Reduction furnace

A reduction furnace and reduction tank technology, applied in the furnace, furnace bottom, furnace and other directions, can solve the problems of low safety, complicated operation, easy material jamming, etc., to ensure stability and accuracy, improve processing efficiency, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

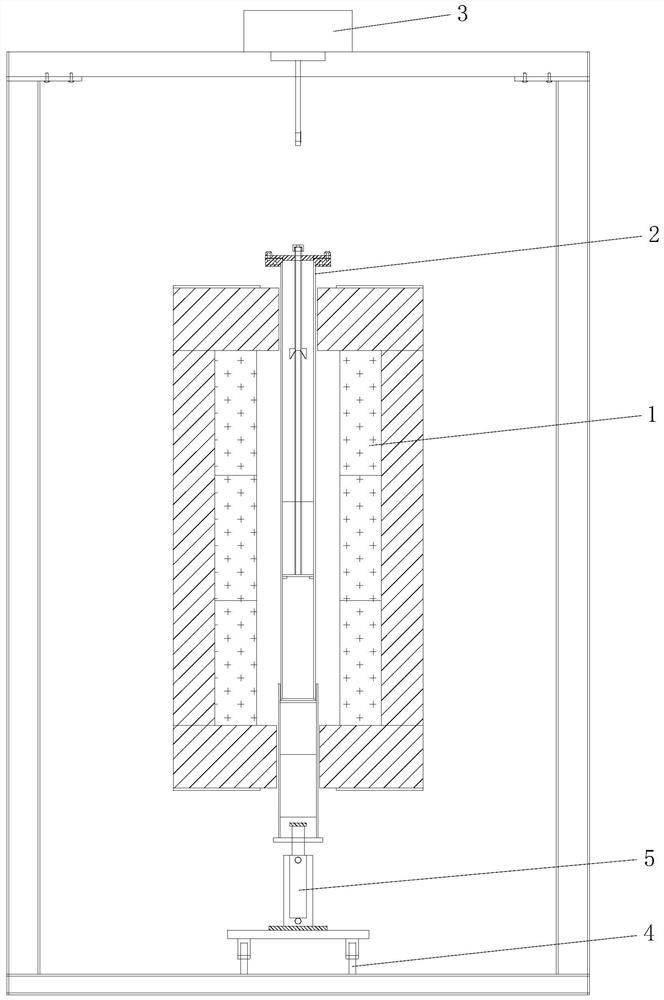

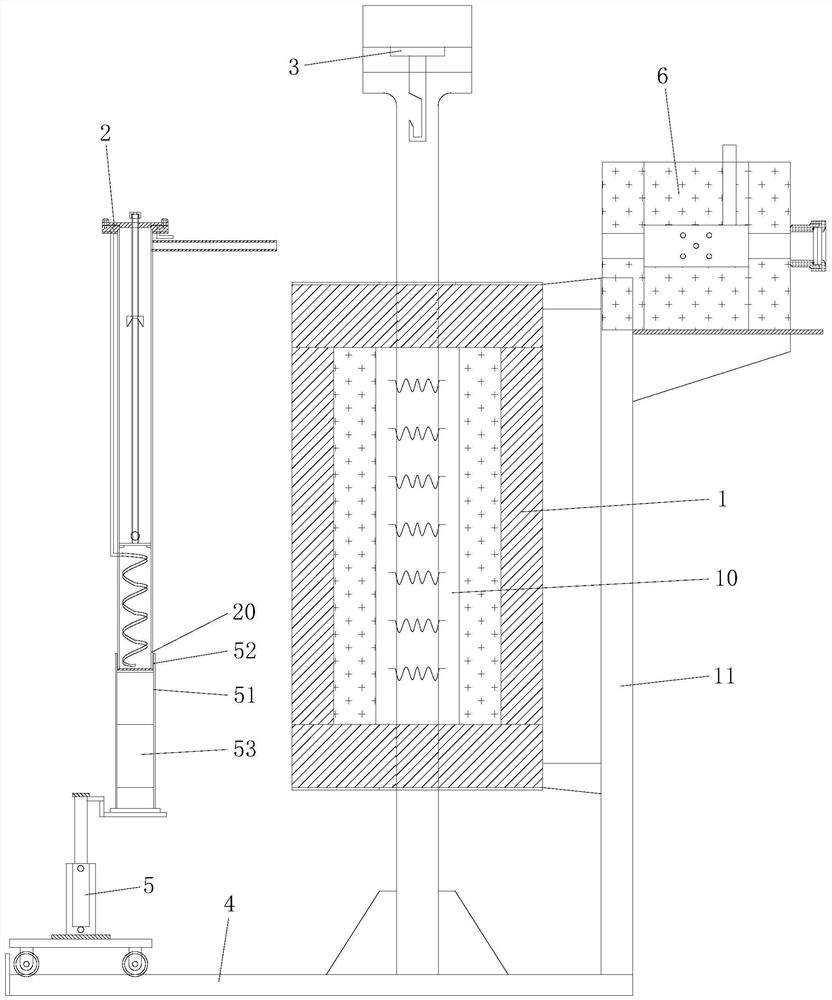

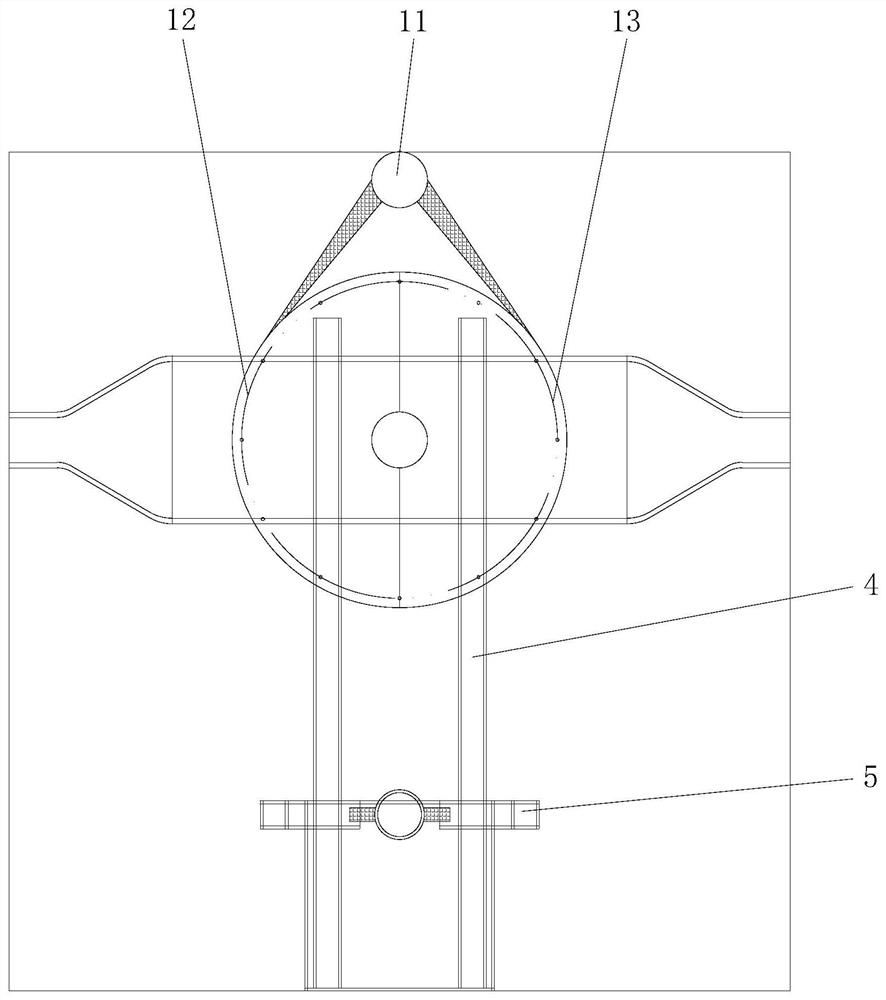

[0032] like Figure 1 to Figure 4 As shown, the reduction furnace of this embodiment includes a heating furnace 1, a reduction tank 2 and a hanging weighing device 3. The heating furnace 1 has a furnace 10 that can be opened and closed, and the hanging weighing device 3 is fixedly arranged on the furnace 10. The upper part is used to hang the reduction tank 2 in the furnace 10, and the reduction furnace also includes a function for moving the reduction tank 2 into the furnace 10 and hanging the reduction tank 2 on the hanging weighing device 3 and lifting the reduction tank 2 from the Take off on the hanging weighing device 3 and move out the loading and unloading tank device of the furnace 10. In this reduction furnace, a hanging weighing device 3 is fixed above the furnace 10 for hanging the reduction tank 2 in the furnace 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com