Automatic air supply control system and method for power plant boiler

A technology of air supply system and power plant, which is applied in the control of combustion, combustion method, and air supply adjustment, etc., which can solve the problem of poor adaptability to load and coal type, large disturbance of automatic adjustment of stability and accuracy of air supply, and deviation of oxygen measurement. It can reduce the working intensity and working pressure, reduce the pressure fluctuation of the furnace, and reduce the insufficient combustion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

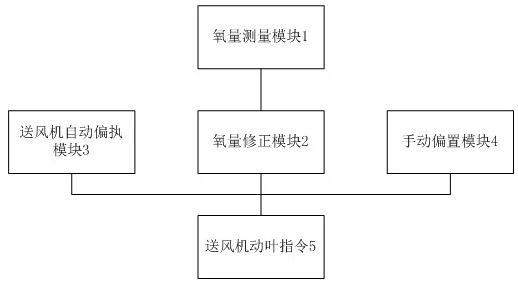

[0031] Such as figure 1 As shown, in this embodiment, an automatic air supply control system for a boiler in a power plant includes an oxygen measurement module 1, an oxygen correction module 2, an automatic blower bias module 3, and a manual bias module 4; The measurement module 1 is connected to the oxygen volume correction module 2, the oxygen volume correction module 2, the blower automatic biasing module 3 and the manual biasing module 4 are connected to obtain the opening command of the air supply rotor blade in the automatic state.

[0032] The oxygen content measurement module 1 includes three oxygen content analyzers installed at the inlets of the air preheater on both sides of the furnace, and the measured values of the oxygen content analyzers are averaged as the actual measured oxygen content of the boiler oxygen content.

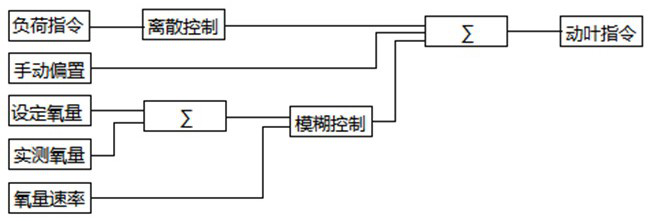

[0033] The oxygen correction module 2 uses a fuzzy control strategy, uses the unit load corresponding to the boiler's optimal oxygen content functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com