Valve train of internal combustion engine

A technology for valve trains and internal combustion engines, which is applied in the directions of machines/engines, connecting components, mechanical equipment, etc., and can solve problems such as complicated switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

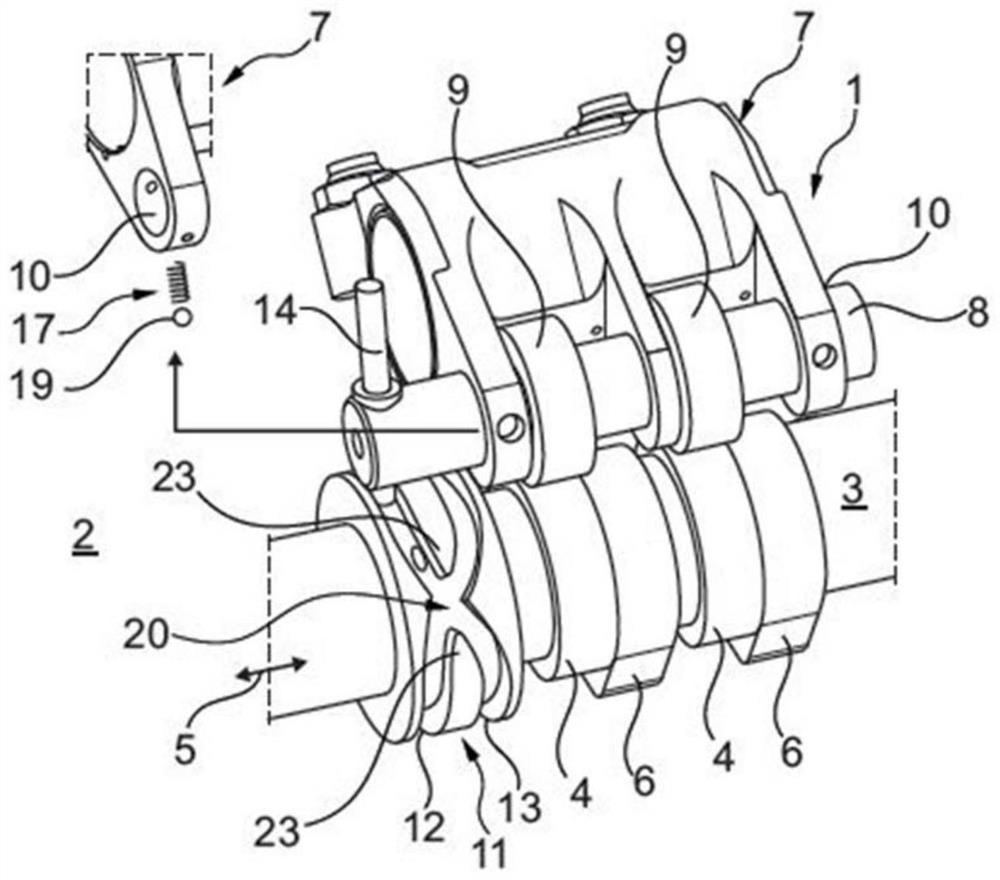

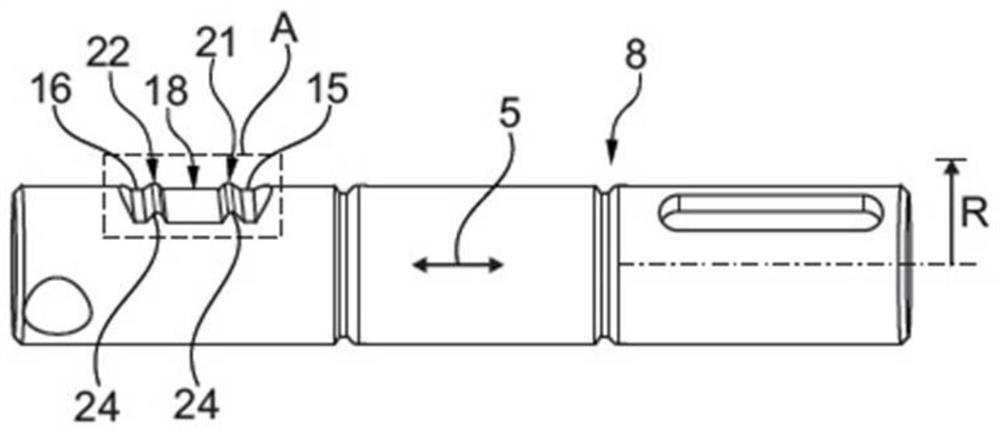

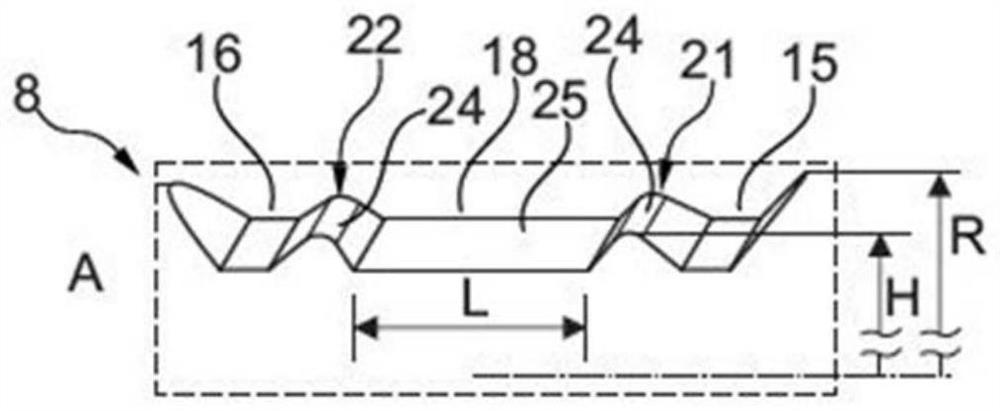

[0027] according to figure 1 According to the invention, a valve train 1 of an internal combustion engine 2 , not shown in detail, has a camshaft 3 comprising a first cam 4 and a second cam 6 adjacent to the first cam 4 in the axial direction 5 . A rocker arm assembly 7 is also provided which includes displacement bolts 8 (see also figure 2 and image 3 ), the displacement bolt 8 is adjustable in the axial direction 5 between at least two positions, and at least one cam roller 9, where two cam rollers 9 are mounted to the displacement bolt 8 in an axially fixed and rotatable manner. The displacement bolt 8 is thus mounted on the associated bearing lug 10 of the rocker arm assembly 7 . A guide profile 11 comprising a first guide track 12 and a second guide track 13 is arranged on the camshaft 3 . A switching pin 14 is additionally arranged in the displacement bolt 8, the switching pin 14 optionally engaging the first or the second guide rail 12, 13 (according to figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com