Cutter suction dredging device easy to rotate

A telescopic device and turntable technology, which is applied to mechanically driven excavators/dredgers, motor vehicles, transportation and packaging, etc., can solve the problems of high cost and low efficiency of hull rotation, achieve small fluctuations, reduce labor costs, Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

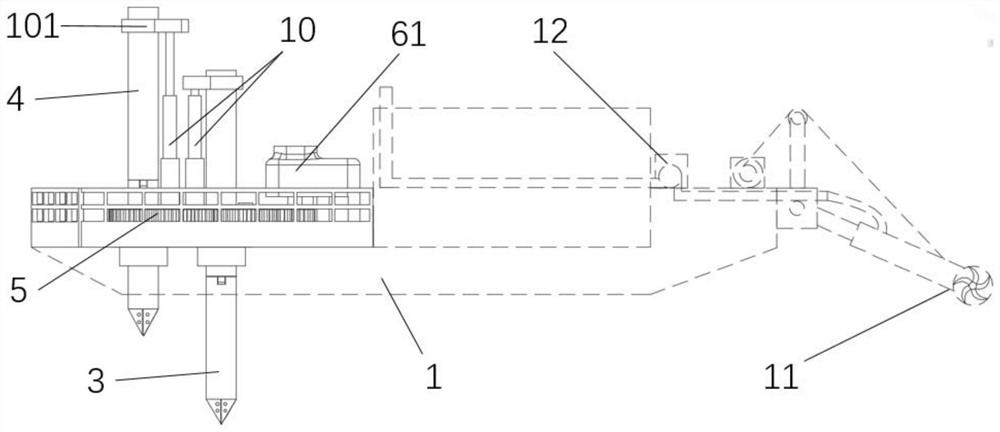

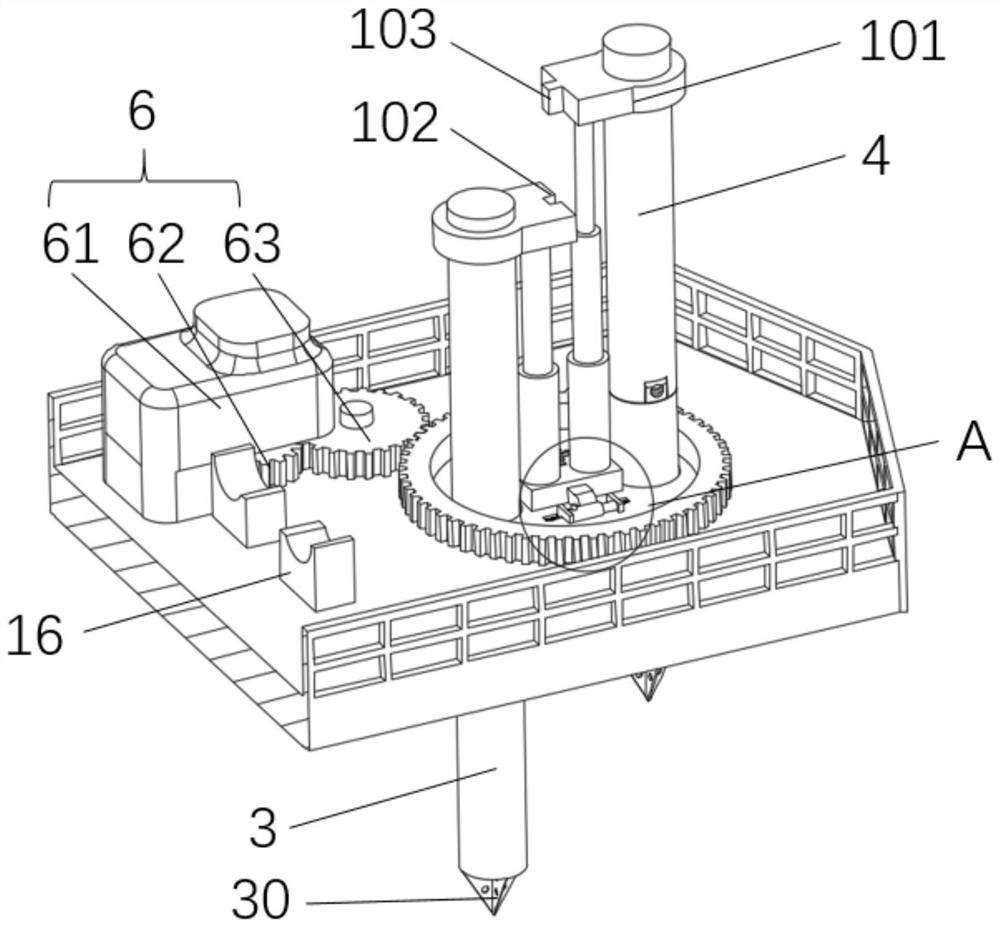

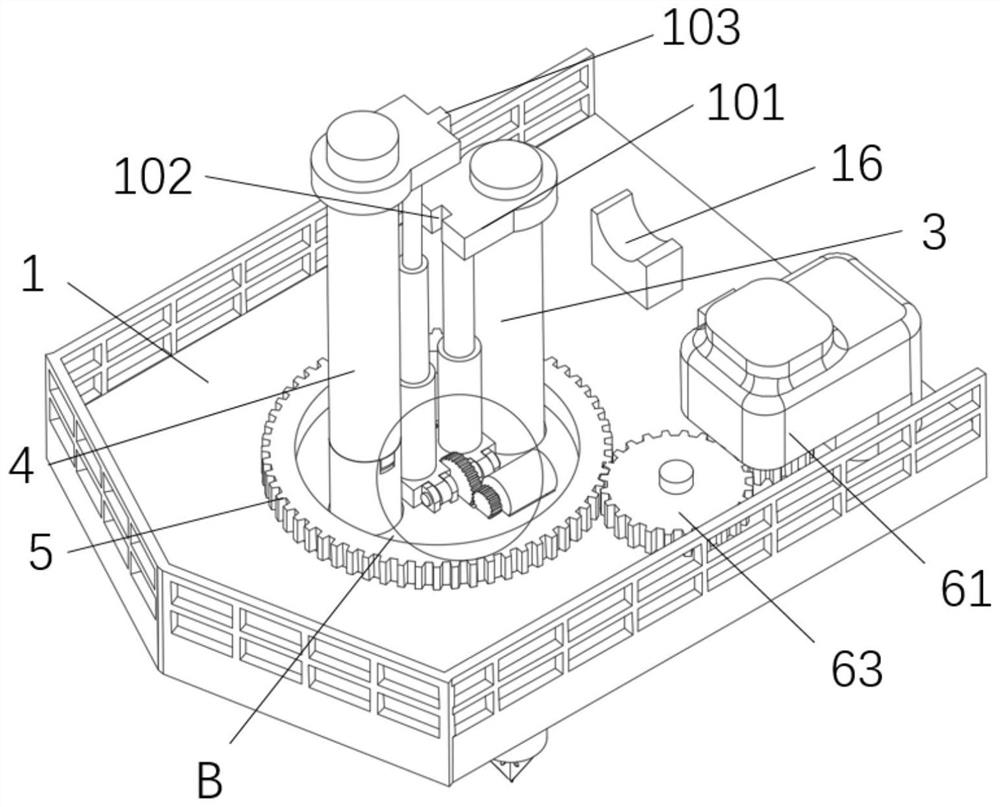

[0038] Such as Figure 1 to Figure 12 As shown, the present invention provides a kind of hinged suction dredging device that is convenient to rotate, comprises hull 1, and one end of hull 1 is provided with hinged suction head 11, and hull 1 is also provided with the mud pump 12 that communicates with hinged suction head 11 , to suck the sludge at the bottom of the river into the pipeline connected to the mud pump 12 by hinge suction head 11; it also includes a turntable 2, which is rotatably arranged at one end of the hull 1; the turntable 2 can be raised and lowered A first positioning pile 3 and a second positioning pile 4 are provided to lower and insert the first positioning pile 3 and the second positioning pile 4 into the bottom of the river for positioning; the turntable 2 is provided with a ring gear 5, and the hull 1 is provided with a driving The power unit 6 that the ring gear 5 rotates drives the ring gear 5 to rotate through the power unit 6, thereby driving the ...

Embodiment 2

[0045] Such as Figure 5 and Figure 10 As shown, in combination with the technical solution of embodiment 1, in this embodiment, the turntable 2 is provided with an annular semicircular groove 23, and the hull 1 is provided with an annular stopper groove 13 corresponding to the annular semicircular groove 23, and the annular semicircular groove 23 and the annular limiter The bit groove 13 is rotatably connected by the ball 14, so that the turntable 2 can be rotatably arranged on the hull 1, and the position of the first positioning pile 3 and the second positioning pile 4 can be adjusted by the rotation of the turntable 2; when the first positioning pile 3 and the second positioning pile 4 are inserted into the river bottom at the same time, the turntable 2 is fixed, and the power device 6 moves on the ring gear 5 to drive the hull 1 to rotate; when the first positioning pile 3 or the second positioning pile 4 is inserted separately At the bottom of the river, the first posi...

Embodiment 3

[0050] Such as figure 2 and image 3 As shown, in combination with the technical solutions of Embodiment 1 and Embodiment 2, in this embodiment, a groove 102 is provided on the socket portion 101 located on the first positioning pile 3, and a groove 102 is provided on the socket portion located on the second positioning pile 4. 101 is provided with a protrusion 103 corresponding to the groove 102, and the protrusion 103 is slidably matched with the groove 102 to lift the first positioning pile 3 and the second positioning pile 4 to the top through the telescopic device 10, so that the protrusion 103 103 enters into the groove 102 to lock the sleeve part 101 on the first positioning pile 3 and the second positioning pile 4, thereby avoiding the sleeve during the folding process of the first positioning pile 3 and the second positioning pile 4 The problem of rotation of the connecting part 101 arises, which effectively improves the accuracy and stability of the folding.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com