Instrument source taking point blockage online cleaning method and device

A cleaning method and source point technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve problems such as inaccurate pressure measurement and poor results, and achieve improved benefits, cleaning accuracy and efficiency , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

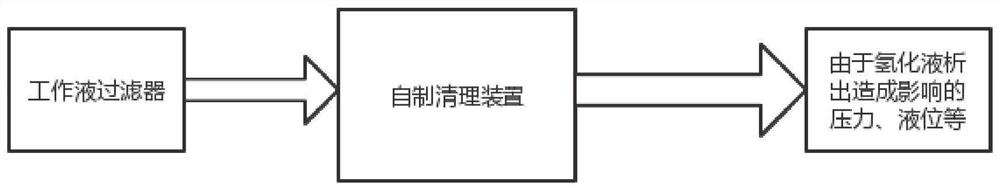

[0021] as attached figure 1 As shown, an online cleaning method for meter source point blockage, including:

[0022] Step S1: Connect one end of the working fluid pipe to the vent pipe of the working fluid filter, and connect the other end to the instrument source point of the equipment to be cleaned;

[0023] Step S2: Open the valve of the vent pipe of the working fluid filter, open the exhaust valve of the working fluid pipe, and use the working fluid to replace the air in the working fluid pipe; When the pressure is consistent with the pressure of the working fluid filter, close the valve of the working fluid filter vent pipe;

[0024] Step S3: Open the valve at the source point of the meter to allow the working fluid to flow into the source point of the meter for cleaning.

[0025] Further, the step S1 is specifically as follows: connect one end of the working fluid pipe to the vent pipe of the working fluid filter, and connect the other end to the instrument source poin...

Embodiment 2

[0034] A cleaning device for an online cleaning method for blockage at the source point of an instrument as described in the above embodiment, comprising: a working fluid filter, a filter vent valve, a working fluid pipe and equipment to be cleaned that are sequentially connected; A ball valve, a pressure gauge and a stop valve are installed. The pressure gauge is set between the ball valve and the stop valve. The outlet end of the working fluid pipe is connected to the working fluid filter through the filter vent valve. The outlet end of the working fluid pipe is connected to the equipment to be cleaned The meter is connected at the source.

[0035] Specifically, an online cleaning method for blockage at the source point of an instrument, a method for disposing of inaccurate pressure caused by the precipitation of hydroanthraquinone under the pressure of the hydrogenation tower, the device used in the method (such as figure 1 Shown) includes 1-working fluid filter (Φ1600*16*2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com