Board pulling mechanism of board discharging machine for light wallboards

A light-weight wallboard and board ejector technology, applied in the field of wallboards, can solve problems such as poor use effect, complex structure, and manual turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

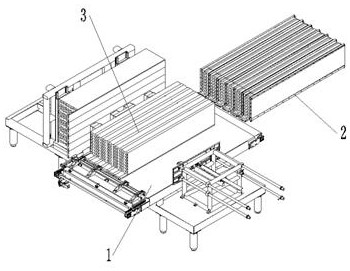

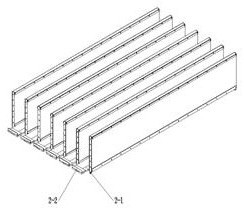

[0032] like Figure 1-7 As shown, a light-weight wallboard ejector, the described ejector 1 is opposite to the mold table 2, and a plurality of light-weight wallboards 3 are placed on the lower formwork 2-1 on the mold table 2 one by one. The lower template 2-1 stretches out a section toward the trigger 1, on which a hanging plate 2-2 is vertically fixedly connected; the trigger 1 includes a chassis 1-1, a flip mechanism 1-2, a pull plate Mechanisms 1-3 and Side Pressing Mechanisms 1-4.

[0033]The turnover mechanism 1-2 is installed on the chassis 1-1, and the turnover mechanism 1-2 includes a first turnover platform 1-2-1, a second turnover platform 1-2-2, and a first turnover platform 1-2-2. The turning platform 1-2-1 and the second turning platform 1-2-2 are all hinged on the underframe 1-1, and the first turning cylinder 1-2-3, The second overturning cylinder 1-2-4, the first overturning cylinder 1-2-3 is connected with the first turnover platform 1-2-1, drives its 90° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com