A Rigid-Flexible Gripper with Large-scale Adjustable Friction Force

A rigid-flexible, frictional technology, applied in the direction of program-controlled manipulators, manufacturing tools, chucks, etc., can solve problems such as inability to apply to high-load conditions, lack of synergy, slow device response, and avoid insufficient load capacity. Overcome the effect of insufficient load capacity and poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

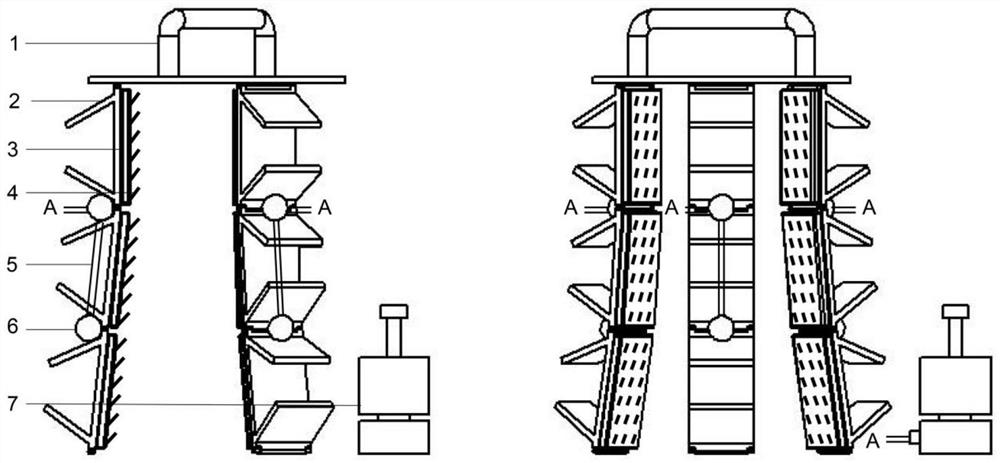

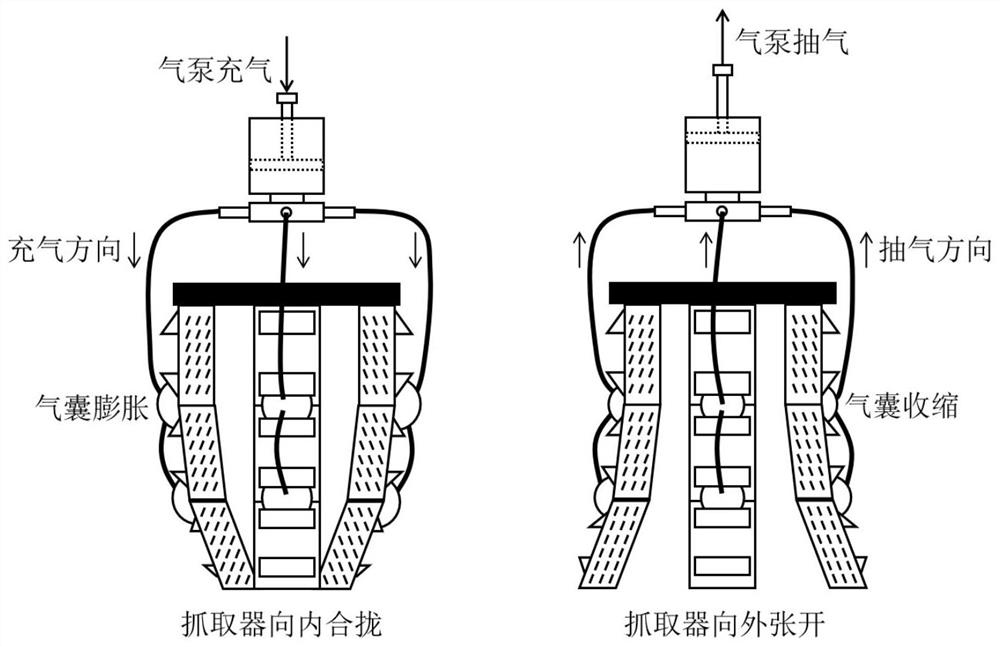

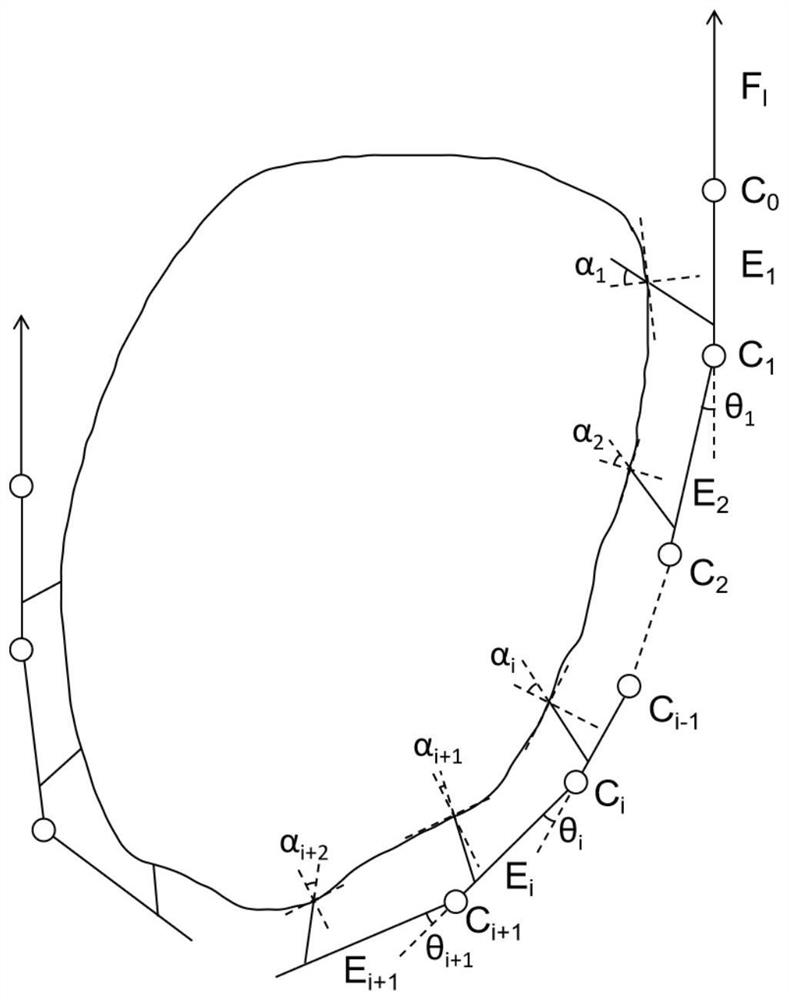

[0041]Please refer tofigure 1 withfigure 2 This embodiment provides a rigid binding apparatus for a wide range of regulatory friction, including a body plate, a handle 1 connected above the body plate, three grab chains connected below the main body plate, three crashes The chain is covered with the object below the main body, in order to capture, the grab chain includes a rigid substrate, used to cover the flexible layer of the object around the object, rigid piercing 4, airbag passage 5, airbag 6 and air pump 7, the handle 1 is inverted U-shape and integral with the main body plate to facilitate the operation of the staff to hold the handle 1, and the three grabbing chains are fixed at the bottom of the main body plate in the main body plate, through three grab links The grabbed object is grasped, and the grabbed chain is gathered by passing the gas to the airbag 6, each rigid substrate gradually rotates so that the flexible layer is surrounded by the object to be grasped, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com