Novel ball screw bearing disassembly device

A technology of bearing removal device and ball screw, which is applied in the direction of hand-held tools and manufacturing tools to achieve the effects of improving adaptability, avoiding surface loss and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

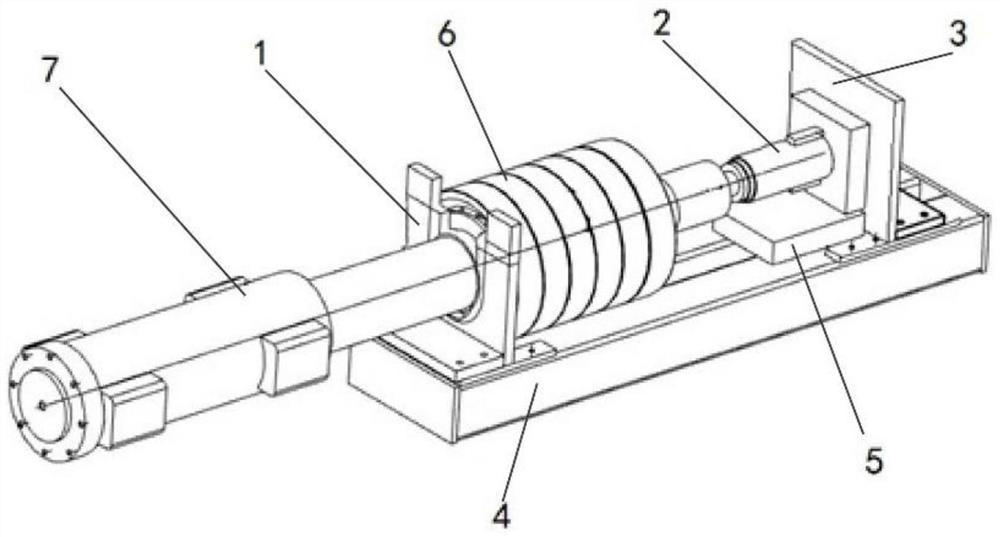

[0022] figure 1 Shown is a new type of ball screw bearing removal device according to the present invention, which includes a tooling base 4 , a front bracket 1 , a rear bracket 3 , an ejection assembly 2 and a backing plate 5 . Lead screw 7 bearing 6 is removed using this device.

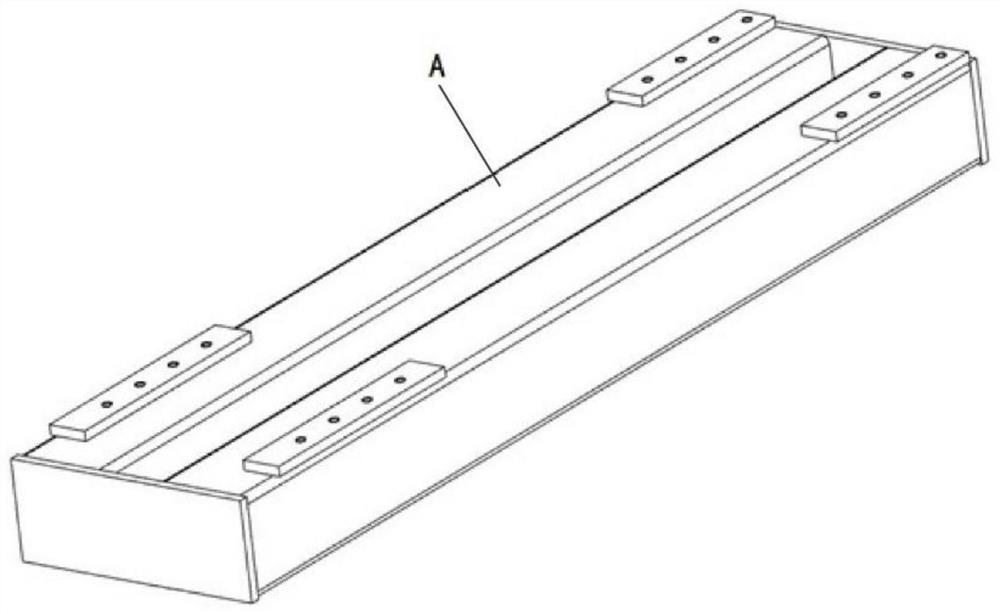

[0023] In this embodiment, the tooling base 4 is a sheet metal part provided with a hollow groove, and the surface A is provided with a plurality of threaded holes at different positions, such as figure 2 shown. The front bracket 1 is provided with a U-shaped groove, and the rear bracket 3 has welded ribs on the back. Both the front bracket 1 and the rear bracket 3 are installed on the tooling base 4 by threaded fasteners according to the size of the lead screw. The front support 1 is parallel to the rear support 3. The distance between the front bracket 1 and the rear bracket 3 can be adjusted through threaded holes fixed at different positions according to requirements.

[0024] Place the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com