Built-in rotor of surface concept permanent-magnet machine

A permanent magnet motor, surface technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of complex structure permanent magnet shape, increased rotor cost, increased surface loss, etc., to avoid surface Loss, low processing cost, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The built-in rotor of the surface concept permanent magnet motor of the present invention will be further described in detail in conjunction with the accompanying drawings and a preferred implementation example:

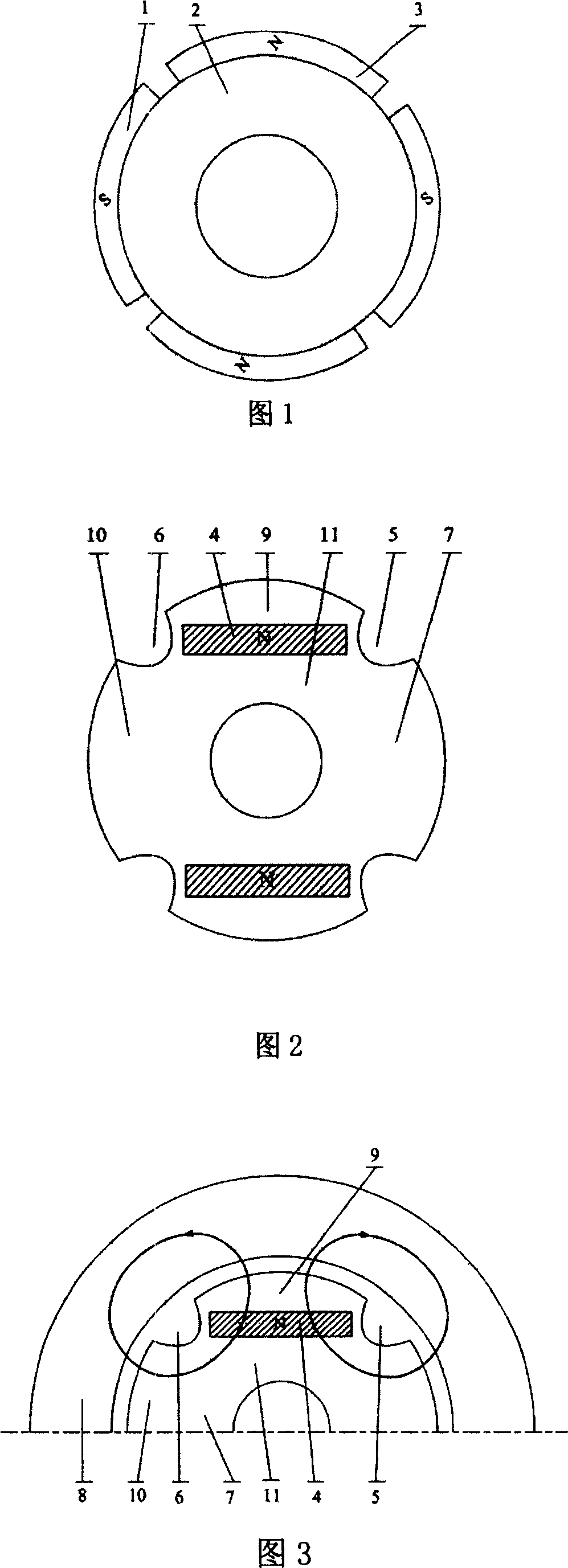

[0028] The surface-type rotor in the prior art is shown in FIG. 1 (taking a four-pole motor as an example), tile-shaped N poles 3 and S poles 1 are alternately placed on the surface of the rotor core 2 .

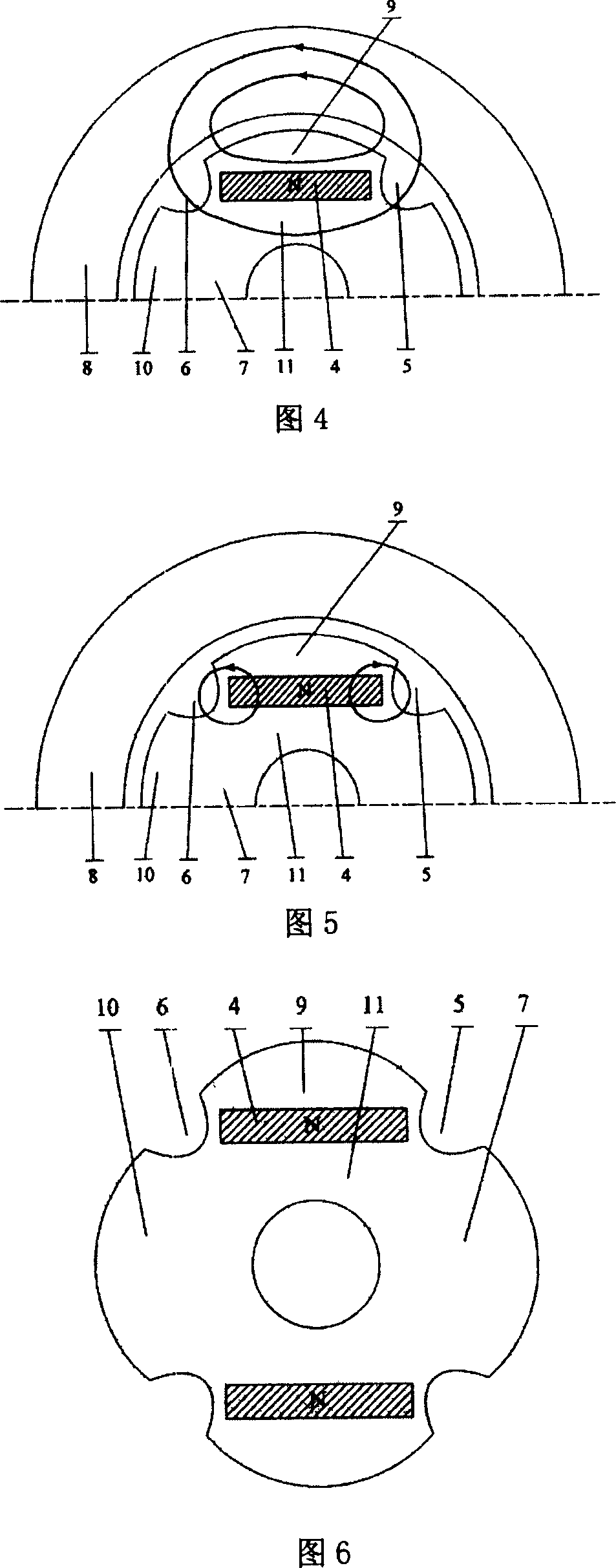

[0029] The built-in rotor of the surface concept permanent magnet motor of the present embodiment is as shown in Figure 2. Compared with the surface rotor structure, the number of permanent magnet blocks is reduced by half, the polarity is the same, and the shape is a regular rectangular permanent magnet 4 (N pole or S poles) are evenly distributed and embedded in the rotor core 7, and pits 5, 6 are set on both sides of each permanent magnet. The path of the direct-axis magnetic circuit is: Starting from the permanent magnet N pole 4, passing through the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com