LED two-face integral multi-specification intelligent machine for FPC board feeding

A multi-specification and integrated technology, which is applied to the device for coating liquid on the surface, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of difficult manual production, high labor intensity of employees, low production efficiency, etc., and achieve reduction The effect of manual labor intensity, reduction of skill requirements, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

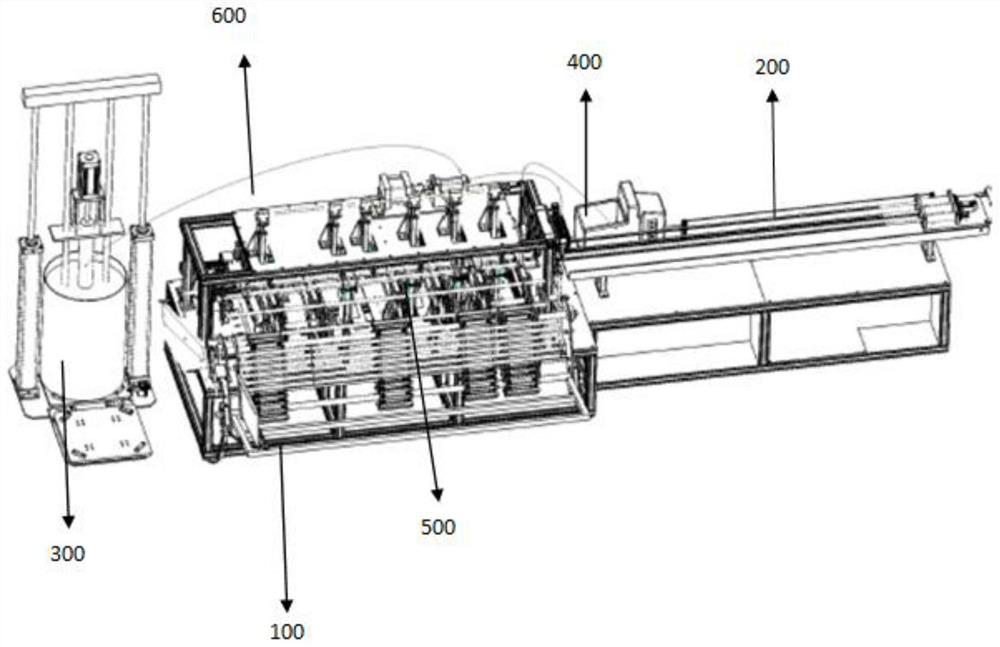

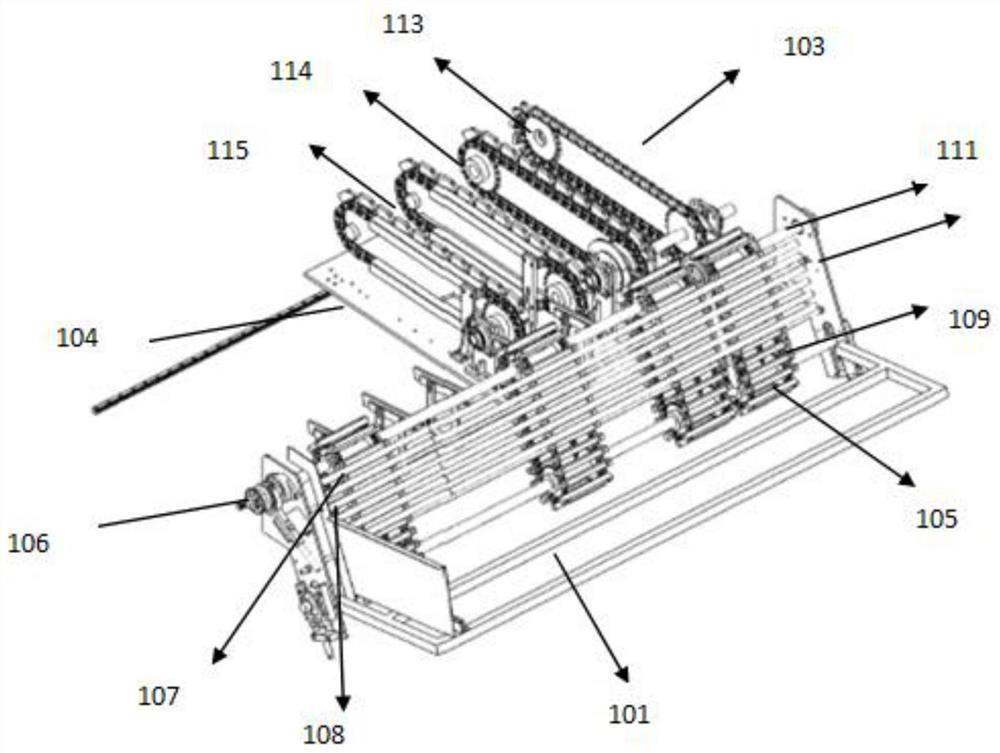

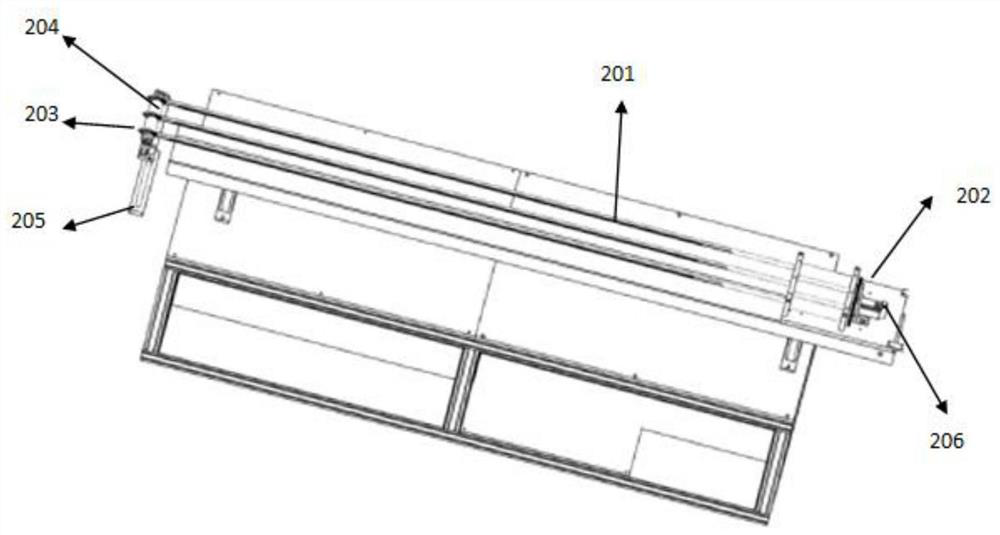

[0032] Such as figure 1 As shown, the present invention discloses a multi-standard intelligent FPC board machine with two sides integrated into one LED, including an upper tube mechanism 100, an upper FPC board mechanism 200, an upper thermally conductive glue mechanism 300, an upper FPC board fixing glue mechanism 400, and an FPC board sticking mechanism 500, down tube mechanism 600. The upper tube mechanism 100 is arranged at the front end of the FPC board sticking mechanism 500, and is mainly used for storing the film tubes that enter the FPC board, and transports the film tubes from the storage tank to the FPC board to wai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com