High-speed vacuum positioning centrifuge

A centrifuge and vacuum technology, applied in the field of centrifuges, can solve the problems of air resistance affecting the centrifugation effect, long waiting time, difficult high-speed centrifugation of centrifuges, etc., to achieve the effects of heat avoidance, convenient access, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Embodiment 1: The large synchronous wheel 43 and the synchronous belt 47 are driven by the servo motor 42, and then the small synchronous wheel 46 and the centrifugal rotor 48 on it are driven, and the U-shaped card slot 49 is positioned by the photosensitive position sensor 52, and the centrifuge runs Before, the refrigeration compressor in the refrigeration box 502 starts to work first, so that the refrigeration pipe 501 cools down the rotor chamber 3, and starts to run the centrifuge after reaching the target temperature. move to seal), and at the same time, the lower electromagnetic valve 8 is closed, so that the centrifuge housing 1 is in a sealed state, then the vacuum pump starts to work, and the centrifugal rotor 48 starts to increase the speed at the same time, and rises to the set speed when the vacuum reaches the standard, and maintains The set time, after reaching the set time, the servo motor 42 controls the centrifugal rotor 48 to decelerate, when the speed ...

Embodiment 2

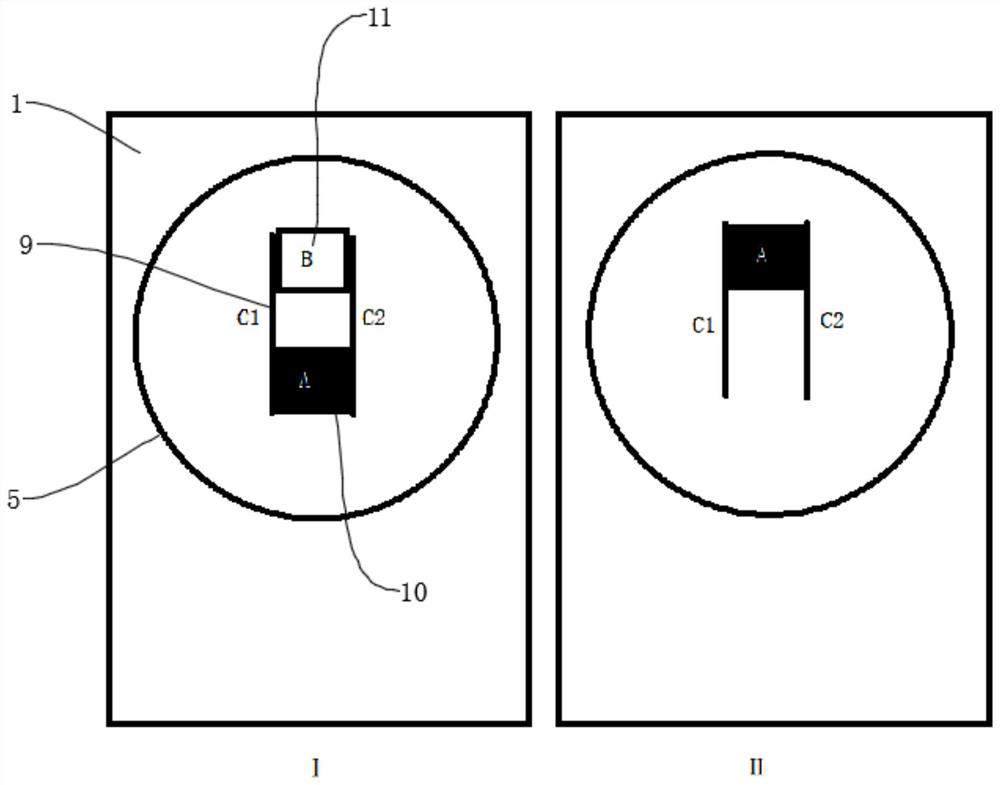

[0032] Embodiment two: if cooperate manipulator E (and manipulator E is the equipment that carries in centrifuge shell 1 in the prior art, for example TG16-WS centrifuge) realize automatic operation, then as Image 6 As shown in middle I, after the slider completely leaves the E part, the manipulator will grab the centrifuge tubes in the 1 and 2 holes in the E range, and then the servo motor will drive the rotor to move to the position of II, 3, 4. The two centrifuge tubes are in the E range, and the manipulator will carry out the grabbing activity again. After grabbing the centrifuge tubes in the 3rd and 4th holes, the servo motor will continue to move, and this cycle will continue until all 12 centrifuge tubes are grabbed, and the manipulator will cooperate with the centrifuge. The operation of the instrument for tube placement is also the same as that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com