A waste residue collection device for waste incineration and its use method

A technology of waste incineration and collection device, applied in separation methods, combined devices, chemical instruments and methods, etc., can solve the problems of insufficient treatment of heavy metals in fly ash, full of danger, environmental pollution, etc., and achieve low prices and reduce pollution. , the effect of good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

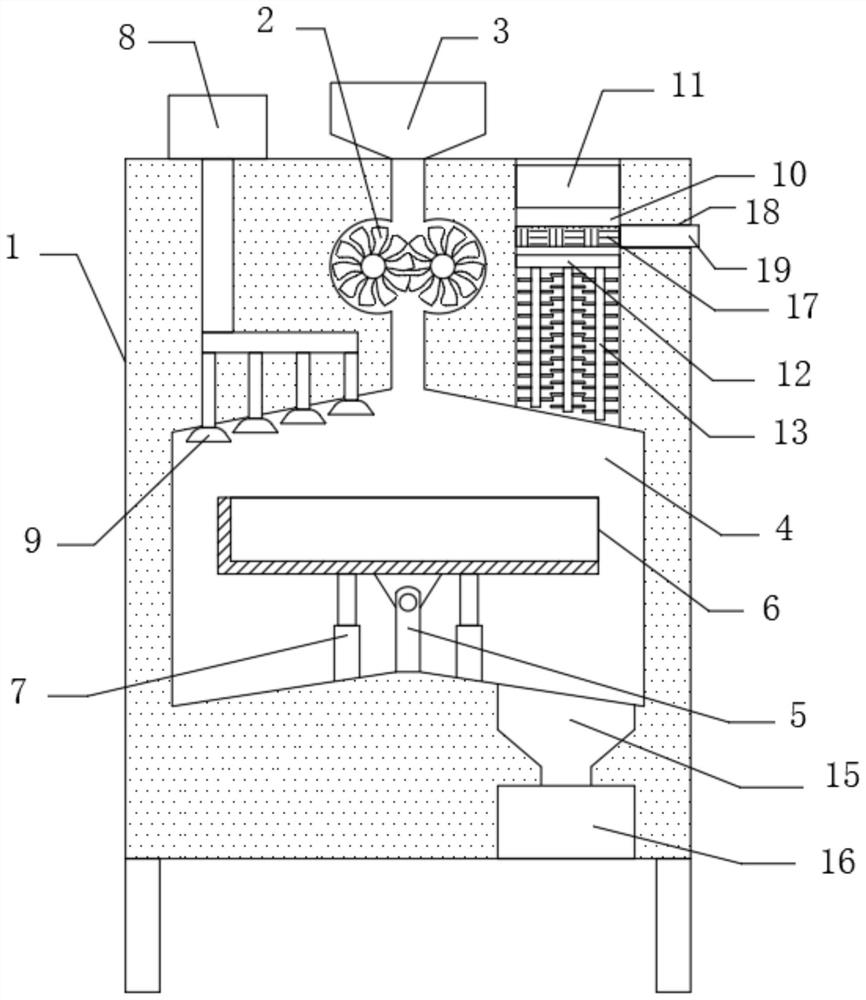

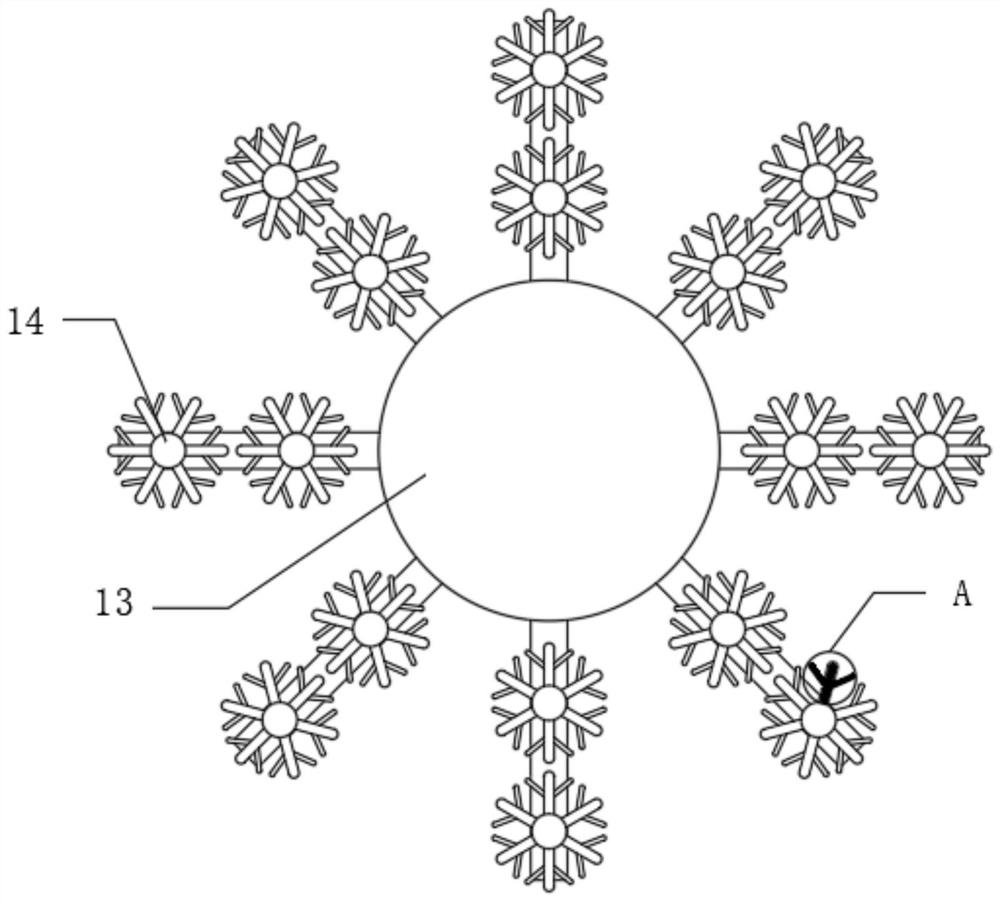

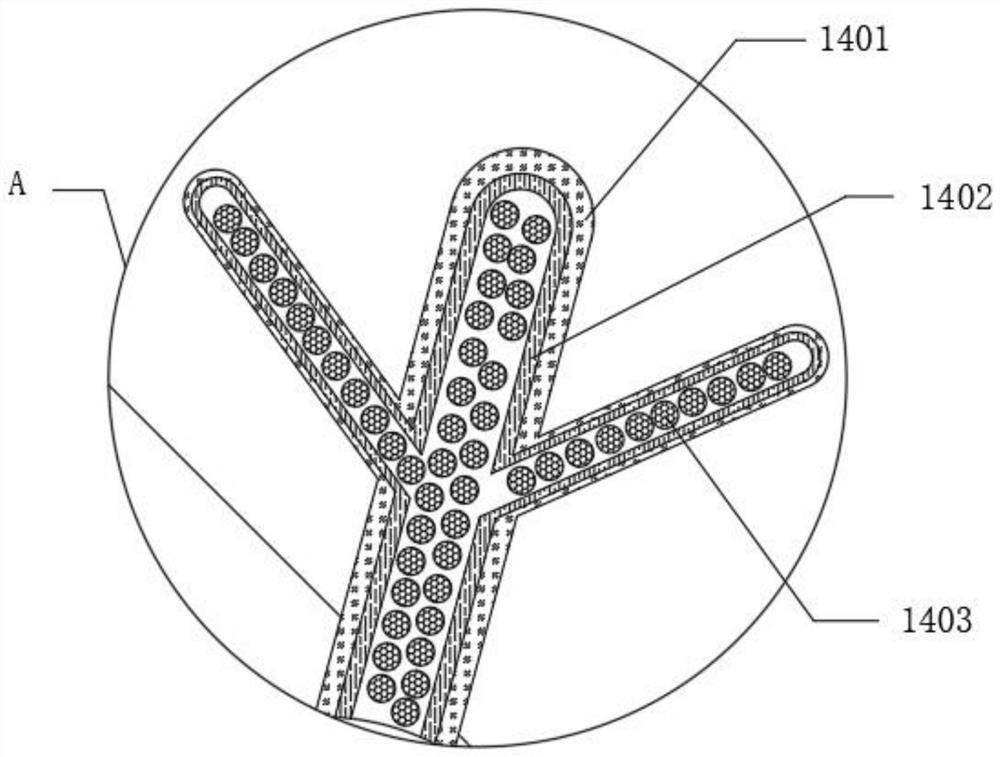

[0043] see Figure 1-5 , a waste residue collection device for waste incineration, including a box 1, please refer to figure 1 and Figure 4, the upper part of the box body 1 is provided with a crushing cavity, and two symmetrical crushers 2 are installed on the inner wall of the crushing cavity, and the blades on the two crushers 2 are dislocated. The middle of the body 1 is provided with a separation cavity 4, the bottom inner wall of the separation cavity 4 is inclined, and the bottom of the separation cavity 4 is inclined to both sides respectively. The inclined bottom allows the solid slag to fall into the blanking cavity 15 smoothly. In order to prevent the fly ash from falling into the blanking cavity 15 when it is blown up, and the separation cavity 4 is communicated with the crushing cavity, the bottom inner wall of the separation cavity 4 is fixedly connected with a bracket 5, and the upper end of the bracket 5 is rotatably connected with a material holding table 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com