Composite freshness-improving product rich in disodium 5'-ribonucleotide, and texture method of composite freshness-improving product

A technology of disodium nucleotide and disodium guanylate, applied in the fields of food microorganisms, fermentation and freshness enhancement of condiments, can solve the problems of large discharge of three wastes and single ingredients contributing to umami taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

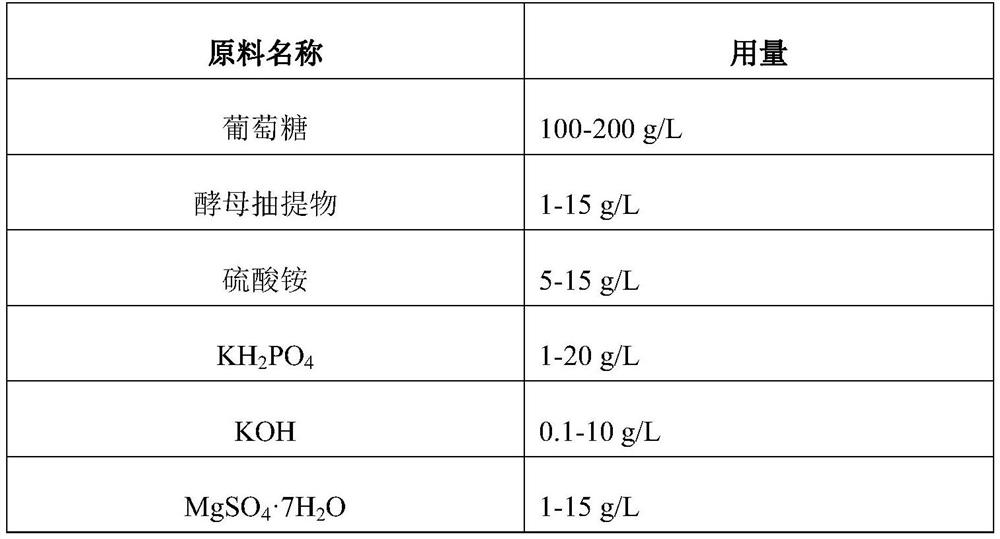

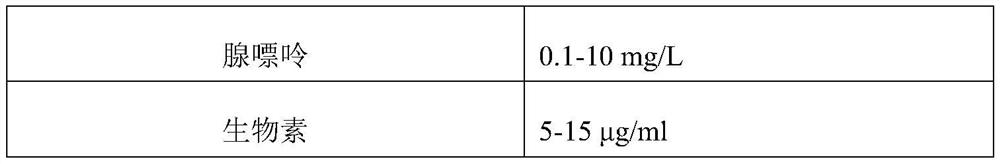

[0021] A compound freshness-enhancing product and texture method rich in disodium nucleotide nucleotides, including fermentation, microfiltration sterilization, enzymatic reaction (specifically GMP texture), concentration, mixing, salting, and drying process, the fermentation refers to Corynebacterium glutamicum, Brevibacterium ammoniagenes, Corynebacterium stagnant, Bacillus amyloliquefaciens, Bacillus subtilis and other strains that produce inosinic acid and guanosine, the strains are 30-37 ℃, pH6.0-8.0, inoculum size 5%-15%, tank pressure 0.05-0.08Mpa, stirring speed 200-1200r / min, ventilation ratio 1:(0.15-0.25) Ferment for 60-150h to get the content It is 3%-18% inosinic acid fermentation broth. Put Bacillus subtilis and other strains capable of producing guanosine under the conditions of 25-45°C, pH 6.0-7.5, inoculum size 5%-10%, tank pressure 0.05-0.08Mpa, stirring speed 200-800r / min Ferment for 40-120 hours to obtain a guanosine fermentation broth with a content of 2%...

Embodiment example 2

[0028]A compound freshness-enhancing product rich in disodium nucleotide nucleotides and a texture method, wherein the microfiltration sterilization refers to heating inosinic acid fermentation liquid and guanosine fermentation liquid at a temperature of 60±10°C to sterilize live, remove the bacteria residue through microfiltration membrane, and obtain inosinic acid filtrate and guanosine filtrate; the enzymatic reaction refers to a kind of phosphotransferase preparation, food grade sodium pyrophosphate and guanosine filtrate, at 30-40 ℃ , pH4.5-6.5 environment to carry out the enzymatic conversion reaction to obtain an enzymatic reaction solution rich in 5'-disodium guanylate; Under the condition of 50-90 ℃ concentrated to the inosinic acid compound paste substance with a dry weight of 50%-70%, the enzymatic reaction solution rich in 5'- disodium guanylate is subjected to negative pressure at -80 to -101kPa Under pressure conditions, concentrate at 50-90°C to a guanylic acid ...

Embodiment example 3

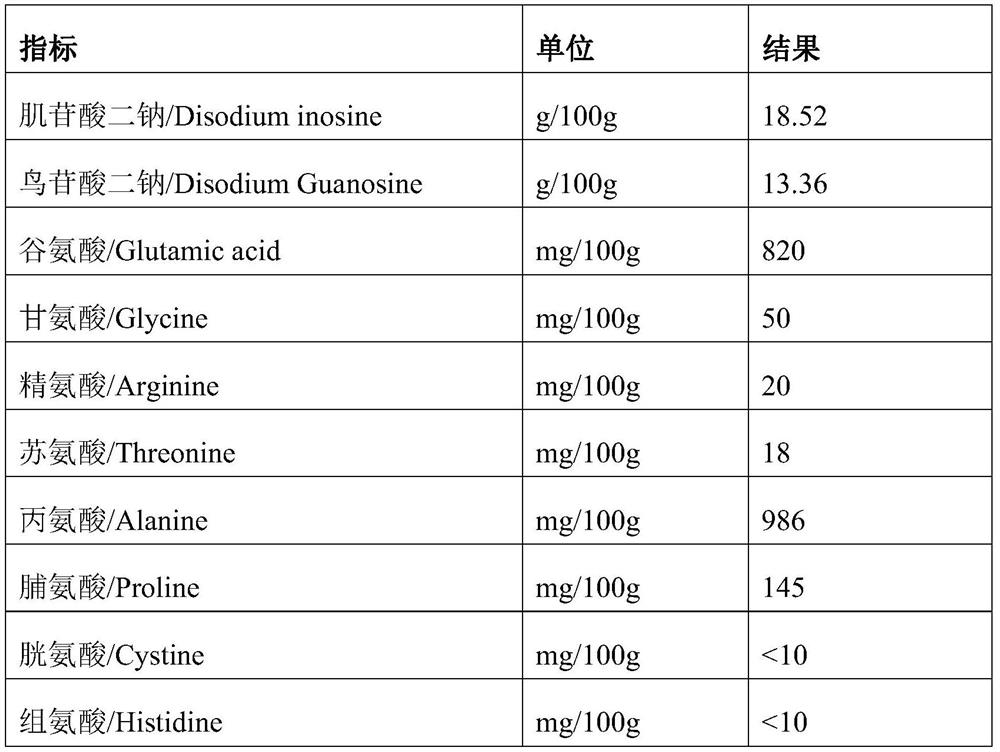

[0032] A compound freshness-enhancing product rich in disodium nucleotide nucleotides and a texture method. The difference from Example 2 is that the mixing is the concentrated inosinic acid compound paste and guanylate compound paste. Mix according to the ratio of dry matter content (2:1) to obtain a new type, compound taste nucleotide disodium (I+G) paste product, which is detected by Agilent high performance liquid chromatography and university gas chromatography. The main nutritional and umami ingredients are composed as follows:

[0033]

[0034]

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com