Long-distance sub-wavelength grating structure applied to optical phased array transmitting unit

A subwavelength grating and optical phased array technology, applied in the field of optical phased array, can solve the problems of high manufacturing cost, high difficulty and cost, complex structure, etc., and achieve the effects of low cost, simple structure and low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

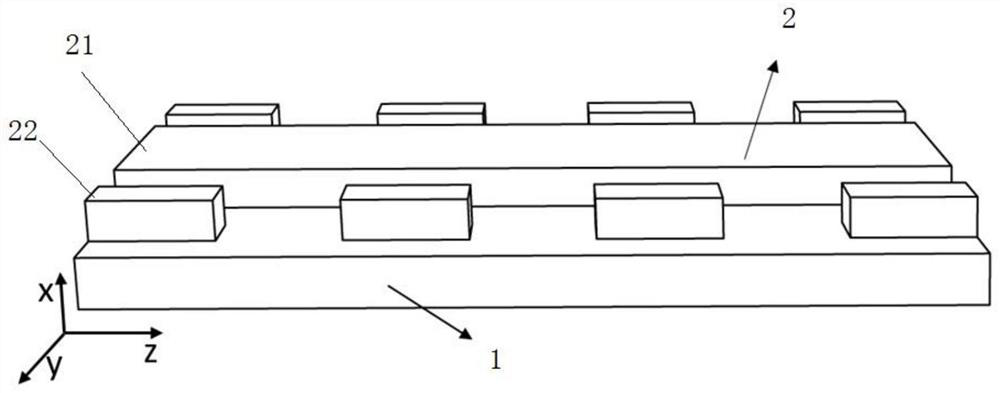

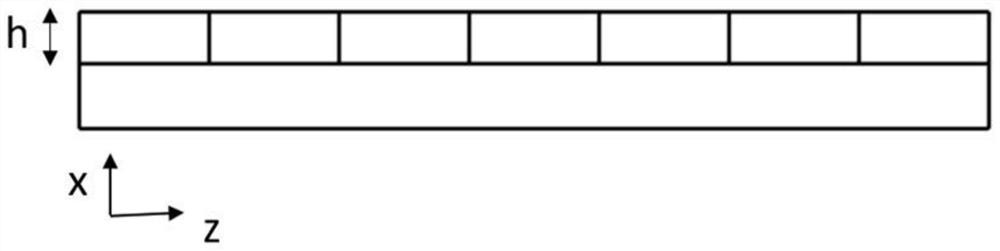

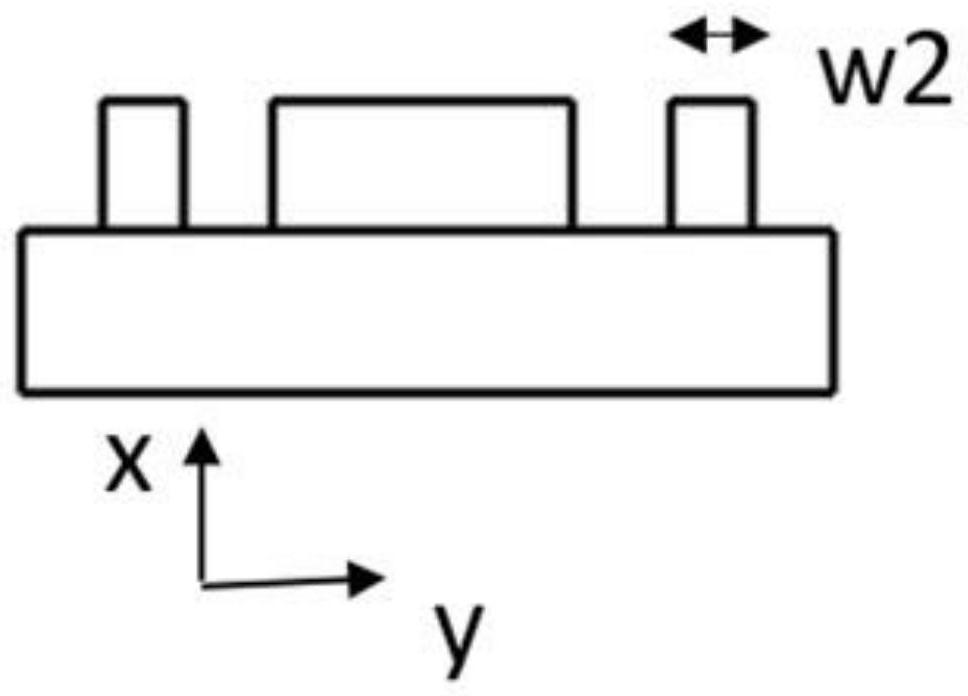

[0022] Such as Figure 1 to Figure 4 As shown, a long-distance sub-wavelength grating structure is used as a transmitting unit to realize a large-aperture optical phased array. The bottom layer is an oxide layer with a thickness of two microns, such as a silicon dioxide layer 1, and the upper layer is A sub-wavelength grating structure 2 of silicon material. The middle part of the structure is a straight waveguide 11 with a width of w1, and the sub-wavelength squares 2 with a width of W2 are periodically arranged along the direction of the waveguide at a distance d between both sides of the straight waveguide 11. The structure is etched on the SOI (Silicon on Insular) platform (not shown in the figure), first etching a layer of silicon dioxide layer 1, and then etching the silicon waveguide above the silicon dioxide layer 1, due to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com