External drive type sealing element

An external drive and seal technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as infirmity, deformation of sealing rings, abutting, and limited use of range, so as to achieve adjustment at any time and improve abutment sealing degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

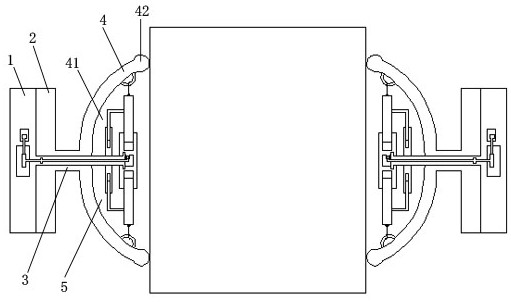

[0020] Such as Figures 1 to 5 As shown, an externally driven seal includes a hard ring body 1, an inner ring body 2, a connecting ring body 3, a sealing ring body 4, and an external adjustment mechanism 5; the hard ring body 1 is installed on the inner side The surrounding outer side of the ring body 2; the surrounding outer middle of the sealing ring body 4 is connected with the surrounding inner side of the inner ring body 2 through the connecting ring body 3; the upper and lower parts of the sealing ring body 4 are curved toward the middle axis Arc-shaped ring structure; the inside of the sealing ring 4 is provided with a built-in annular cavity 41; the upper and lower ends of the sealing ring 4 are respectively provided with abutment rings 42; the abutment rings 42 is made of high elastic rubber material; the external adjustment mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com