Winding device for multi-layer uniform winding, control system and control method thereof

A winding device and control system technology, which is applied in the field of automatic cable winding equipment, can solve problems such as cable overlapping and locking wires, and achieve less signal lines between circuits, flexible and reliable installation, and regular cable arrangement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

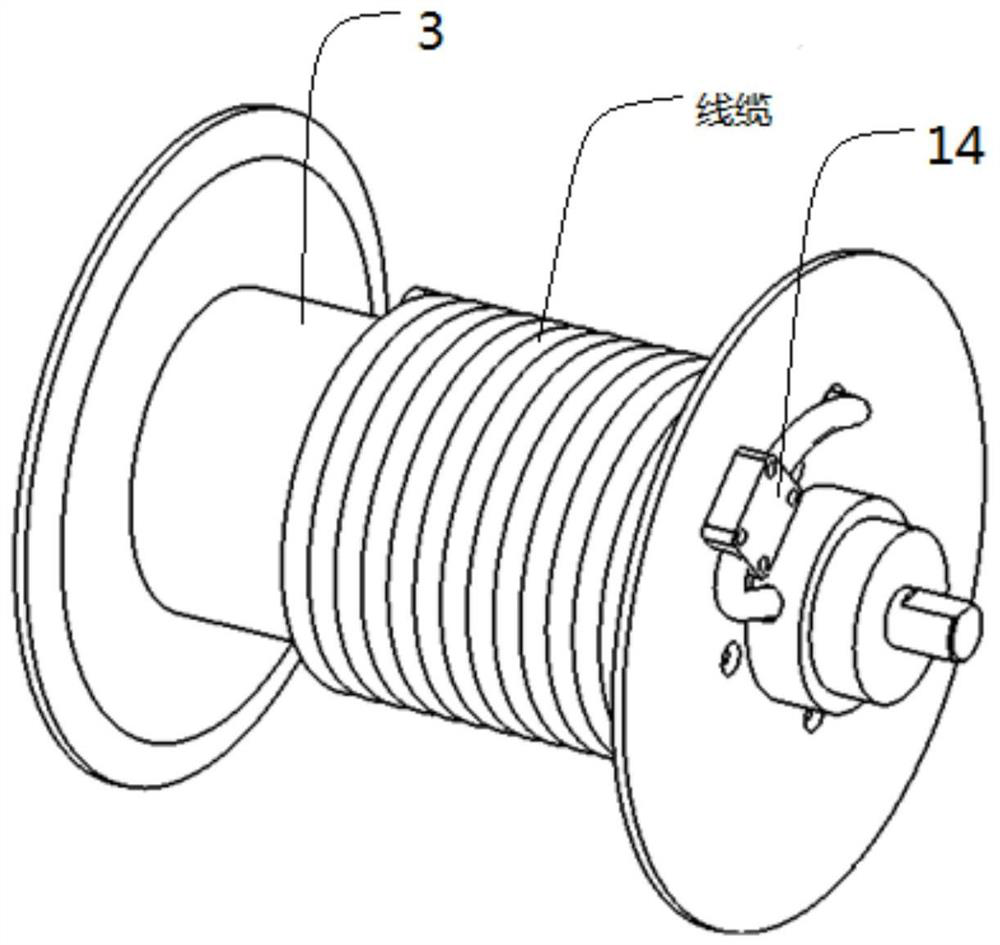

[0057] This embodiment provides a winding device for multi-layer uniform winding, such as Figure 1-3 As shown, it includes the frame 1 and the wire feeding wheel 2 installed on the frame 1 in sequence, the conductor card 13, the router, the cable drum 3, and the wire feeding that drives the wire feeding wheel 2, the router, and the cable drum 3 respectively. Wheel motor 8, screw mandrel motor 9 and cable drum motor 10. The router includes a threaded mandrel 4 installed on the frame 1 and a wiring wheel 6 mounted on the threaded mandrel 4 through a wiring slider 5 . The router also includes a polished rod 11 installed on the frame 1 , and the wiring slider 5 is slidably connected to the polished rod 11 and screwed to the threaded rod 4 . A photoelectric switch sensor 7 is also installed on the corresponding frame 1 on both sides of the wiring wheel 6, and the photoelectric switch sensor is used in conjunction with the photoelectric contact plate 12 provided on the wiring slid...

Embodiment 2

[0060] This embodiment provides the control system of the above winding device on the basis of Embodiment 1, so as to realize the precise control of the operation of each motor of the winding device and achieve the purpose of neat and orderly winding arrangement.

[0061] Such as figure 1 As shown, the control system of the winding device for multi-layer uniform winding provided in this embodiment includes a motor drive module group, a photoelectric signal acquisition module 19, and a main control unit electrically connected to the motor drive module and the photoelectric signal acquisition module 19 respectively. Module 15. The motor drive module group is used to control the operation of the wire feeding wheel motor 8, the screw motor 9 and the cable drum motor 10, and feeds back the collected motor signals to the main control module; the photoelectric signal acquisition module is used to collect the photoelectric signal sent by the photoelectric switch sensor. Switching ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com