Unloading frame for logistics cargo transport

A technology of cargo transportation and logistics, which is applied in the directions of transportation and packaging, loading/unloading, roller tables, etc., which can solve the problems of providing buffers for goods, failing to meet the needs of use, and poor unloading effects. It achieves simple structure, good unloading effect, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

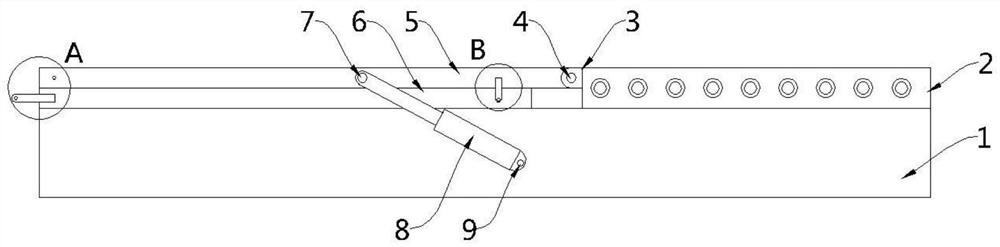

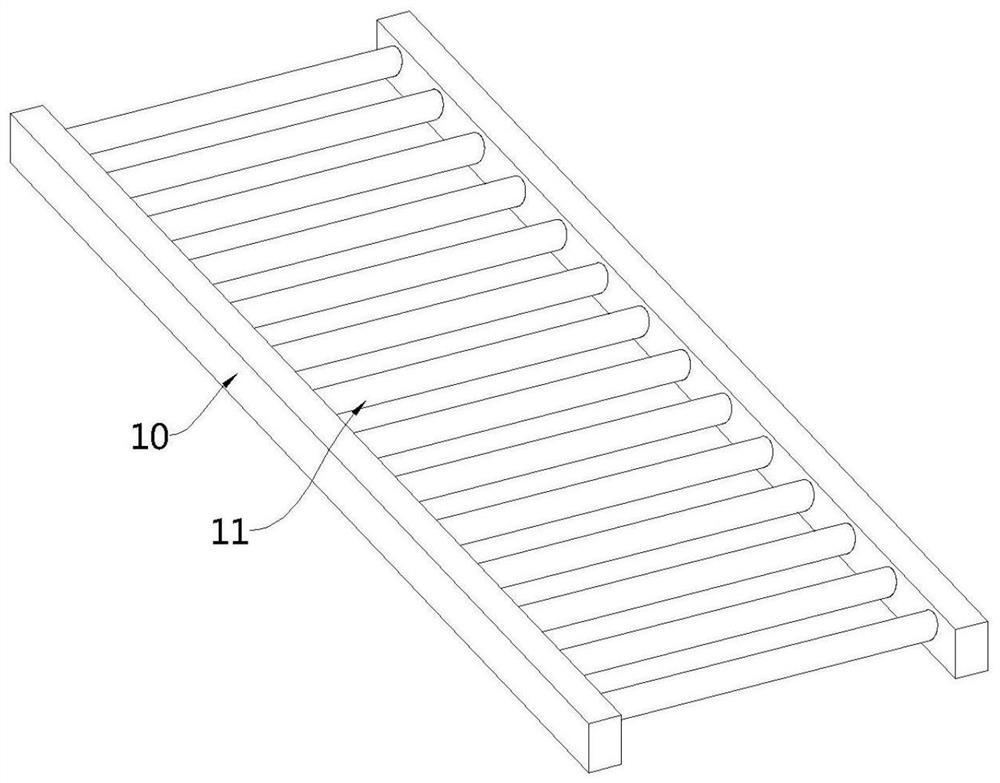

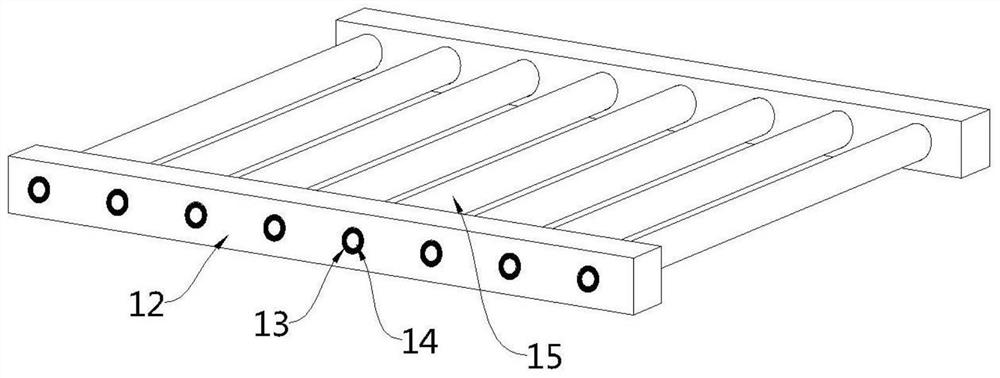

[0026] see Figure 1-3 , this embodiment provides an unloading rack for logistics cargo transportation, including a base 1, a deceleration assembly 2 is provided on one side of the upper part of the base 1, and a first unloading assembly 5 is provided on the other side, and the first unloading assembly 5 is provided The assembly 5 is rotatably connected to one side of the deceleration assembly 2, and the front and rear sides of the base 1 are symmetrically provided with a power assembly 8 for driving the first unloading assembly 5 to rotate upwards. Specifically, the deceleration assembly includes 2 Two sets of second support side plates 12 fixedly arranged on the upper part of the base 1, the two sets of second support side plates 12 are oppositely arranged, and a number of equal intervals are arranged between the two sets of second support side plates 12 along the length direction. The second roller shaft 15, the two ends of each group of the second roller shaft 15 are rotat...

Embodiment 2

[0036] see Figure 4-5 , an unloading rack for logistics cargo transportation. Compared with Embodiment 1, the side wall of the end of the first supporting side plate 10 corresponding to the second unloading assembly 6 in this embodiment is fixedly provided with a first fixing rod 16, so One end of the first fixing rod 16 extends to the side of the first supporting side plate 10, and the first fixing rod 16 is provided with a first through hole 17, and the corresponding first supporting side plate 10 side of the first unloading assembly 5 The wall defines a first concave hole 18 corresponding to the first through hole 17 .

[0037] When the second unloading assembly 6 is extended to one end of the first unloading assembly 5, the first fixing rod 16 extends to the side of the first supporting side plate 10 corresponding to the first unloading assembly 5, and the first through hole 17 and The positions of the first concave holes 18 are aligned, and a pin is inserted from the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com