Material packaging machine and work method thereof

A packaging machine and material technology, applied in the direction of packaging, pressurized/gasification packaging, etc., can solve the problems of unstable steps, low degree of automation, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

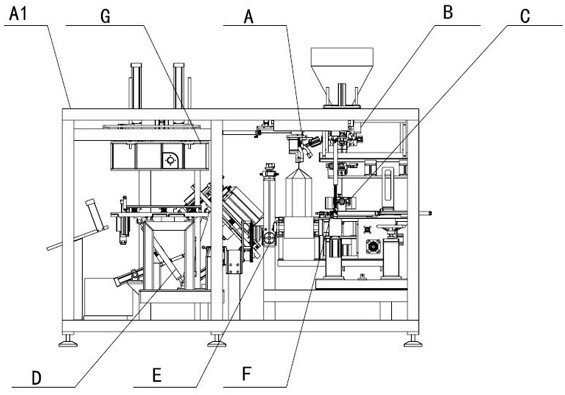

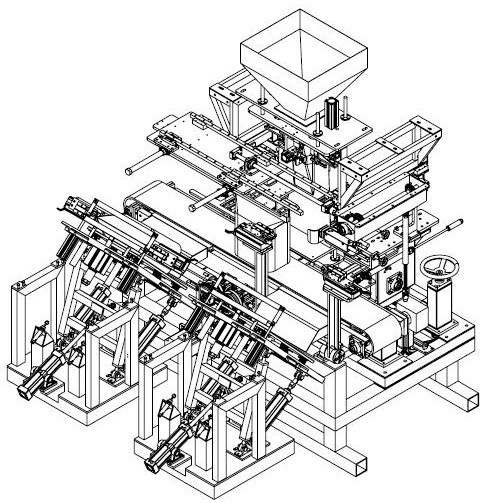

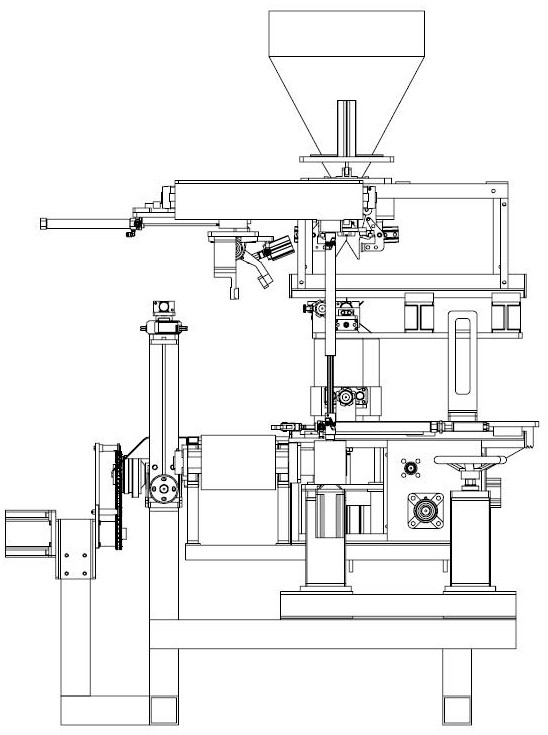

[0050] Such as Figure 1~32 As shown, the material packaging machine includes a material bag filling and clamping mechanism B, a material bag moving clamp C is provided under the material bag filling and clamping mechanism, and a bag clamping port is provided on the side of the material bag filling and clamping mechanism The moving mechanism A moves the material bag to the flipping bag gripping mechanism F through the turning manipulator mechanism E on the side of the bag gripping mouth moving mechanism, and a vacuum chamber mechanism G is arranged above the turning bag gripping mechanism.

[0051] In the embodiment of the present invention, the material bag filling and clamping mechanism includes a support plate B1 installed on the frame A1, and a filling cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com