Anti-blocking rubber forming device

A rubber molding and rubber molding machine technology, applied in transportation and packaging, dispersed particle filtration, application, etc., can solve the problems of increasing the labor intensity of operators, affecting the continuity of the molding device, and lacking a fast feeding mechanism, and reducing labor. Strength, safe and convenient use, and the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

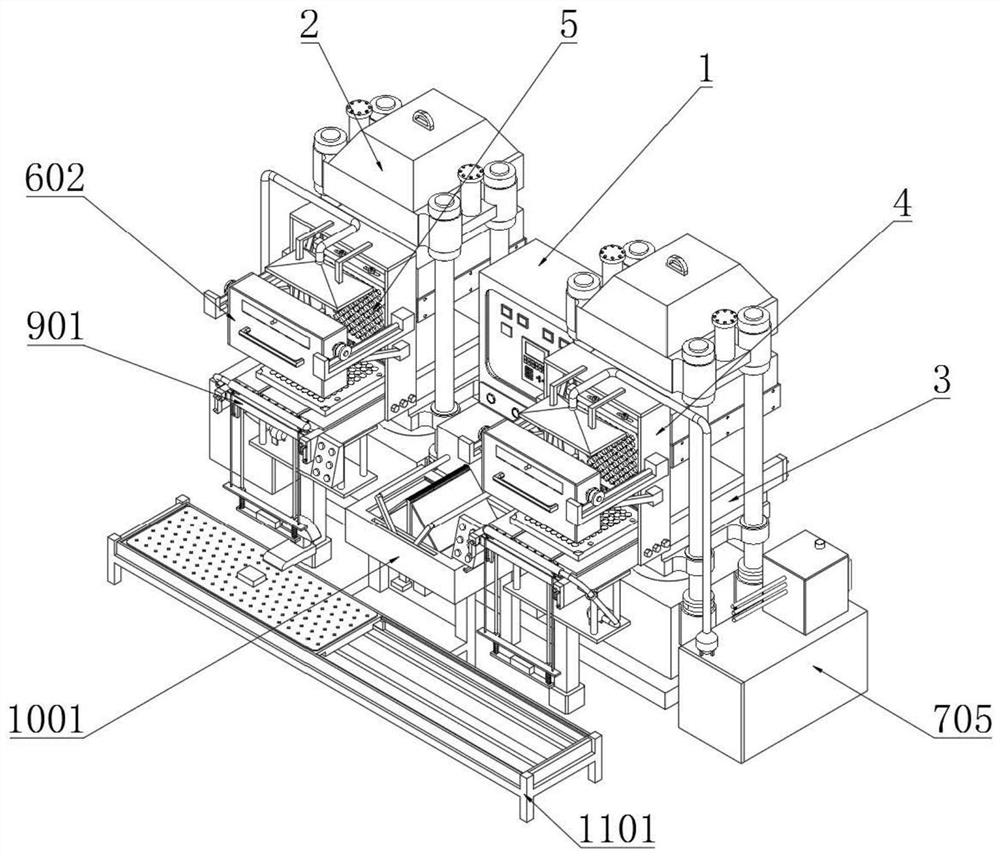

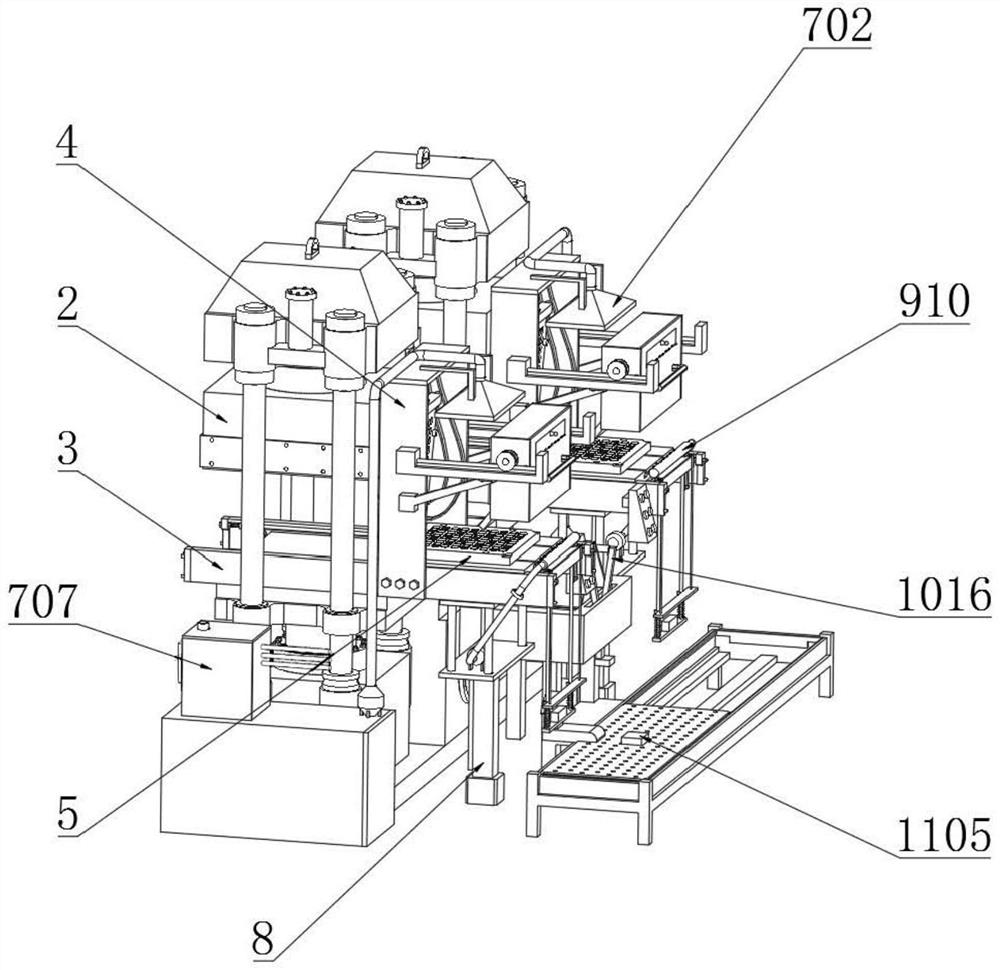

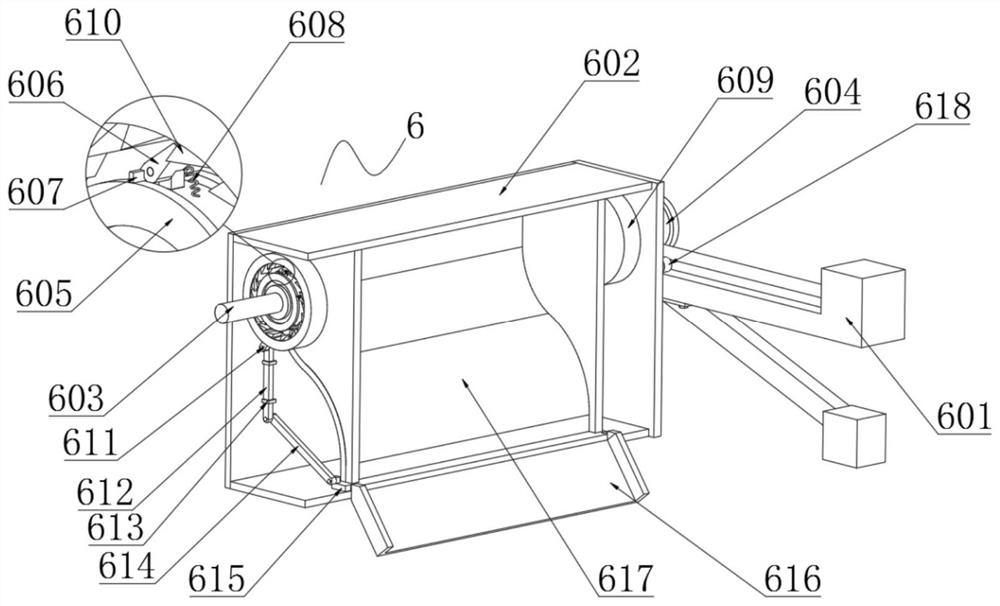

[0035] Example: such as Figure 1-10An anti-blocking rubber molding device shown includes a rubber molding machine control box 1, an equidistant feeding mechanism 6, an exhaust gas treatment mechanism 7, a mold cleaning mechanism 9, a finished product collection mechanism 10, a fast moving mechanism 11, and an exhaust gas treatment mechanism. The side wall of the deodorization box 707 in 7 is fixedly connected with a plurality of electric cleaning push rods 710, the quantity of the electric cleaning push rods 710 is the same as that of the activated carbon filter screen 708, and the output rod of each electric cleaning push rod 710 is fixedly connected with a brush Plate 711, the lower end of the brush plate 711 is fixedly connected with a brush filament 712, and the side wall of the deodorization box 707 is positioned at the lower side and the upper side of the activated carbon filter screen 708, and an inlet pressure sensor 713 and an outlet pressure sensor 714 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com