Drilling and cutting device for stainless steel product machining

A cutting device, stainless steel technology, applied in the direction of feeding devices, manufacturing tools, metal processing equipment, etc., can solve the problems of large space occupation, single cutting or drilling function of the device, high cost, etc., to improve stability and reliability, improve The effect of processing efficiency and processing quality, flexible and convenient operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

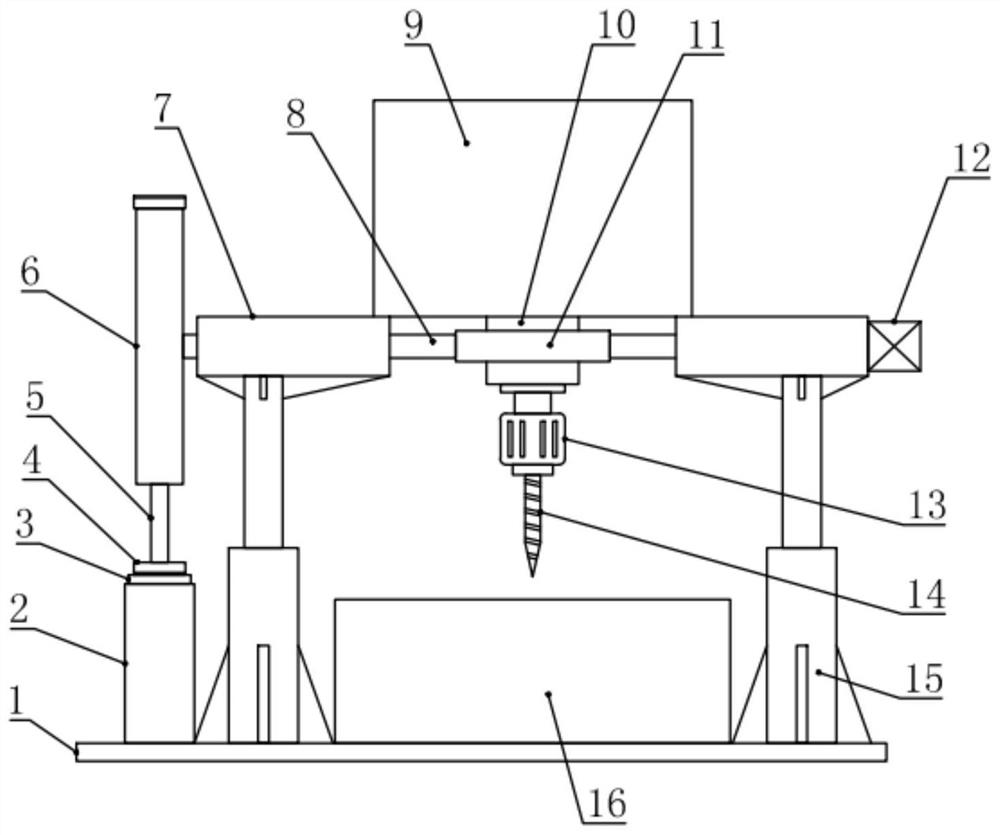

Embodiment 1

[0018] see Figure 1-2 , in an embodiment of the present invention, a drilling and cutting device for processing stainless steel products includes a base 1, a support base 2 and a processing table 16, the support base 2 and the processing table 16 are installed and fixed on the base 1, and the processing table The top of 16 is also fixed with a rotating support assembly through a plurality of telescopic cylinders 15. The middle part of the rotating support assembly is fixed with a double-axis extension motor 10, and the output shafts on both sides of the double-axis extension motor 10 are respectively detachably equipped with drill bits. 14 and a cutting wheel 17, one end of the rotating support assembly is also equipped with an overturning motor 12 for driving the biaxial extension motor 10 to perform 180° flipping, and the other end of the rotating support assembly is also installed with a motor for turning the biaxial extension The motor 10 is a positioning assembly for pos...

Embodiment 2

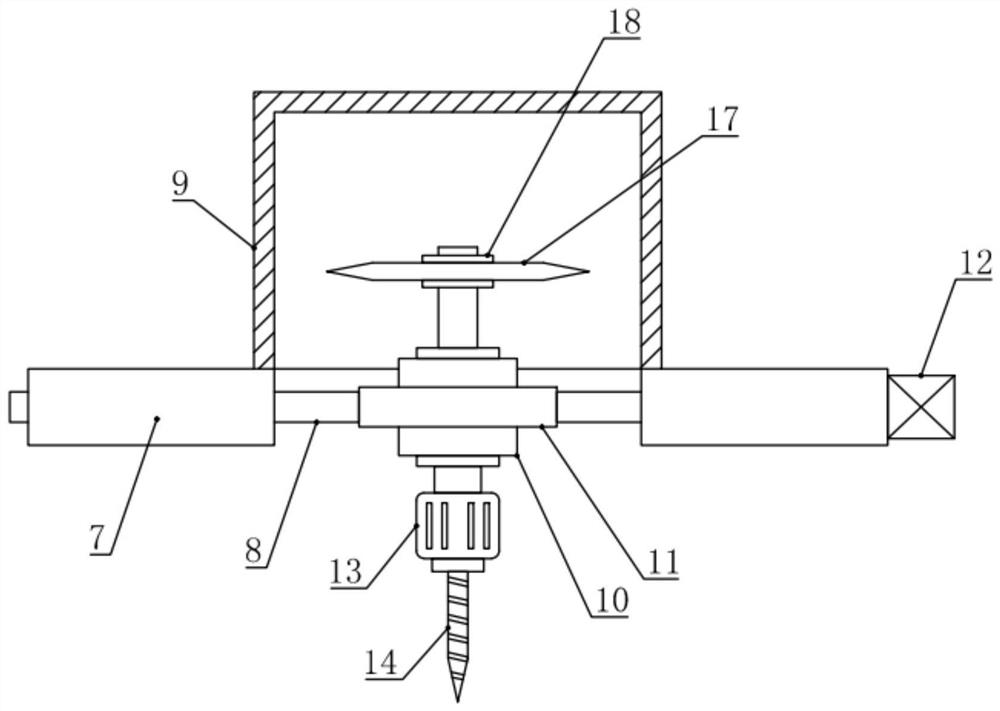

[0021] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

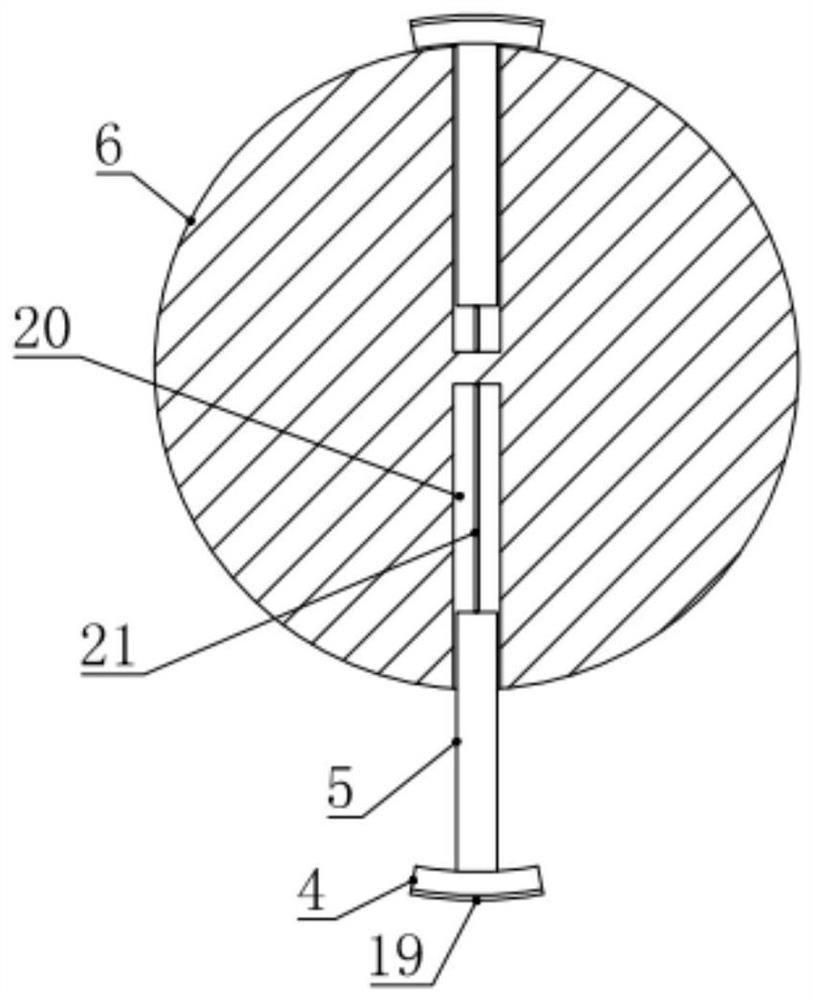

[0022] In this example, if figure 1 , 2 As shown in and 4, the rotating support assembly includes a support cylinder 7, a support shaft 8 and a motor fixing ring seat 11, two of the support cylinders 7 are arranged horizontally, and a The supporting shaft 8, the opposite ends of the two supporting shafts 8 are installed and fixed with a motor fixing ring seat 11, and the biaxial extension motor 10 is installed and fixed on the motor fixing ring seat 11; the lower sides of the two supporting cylinders 7 A telescopic cylinder 15 is respectively installed and fixed, and the lower end of the telescopic cylinder 15 is fixed on the base 1. Through the cooperation of the support shaft 8 and the motor fixing ring seat 11, the biaxial extension motor 10 can be stably rotated and supported, and the telescopic cylinder 15 can drive the rotational support Components move up and down.

[0023] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com