Temperature control island for realizing intelligent control based on die-casting production die

A technology of intelligent control and mold temperature, which is applied in the field of mold temperature control, can solve the problems of high manual operation skills, parameter changes, and failure to detect faults in time, so as to reduce manual manual operations, realize automatic control, and avoid product defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

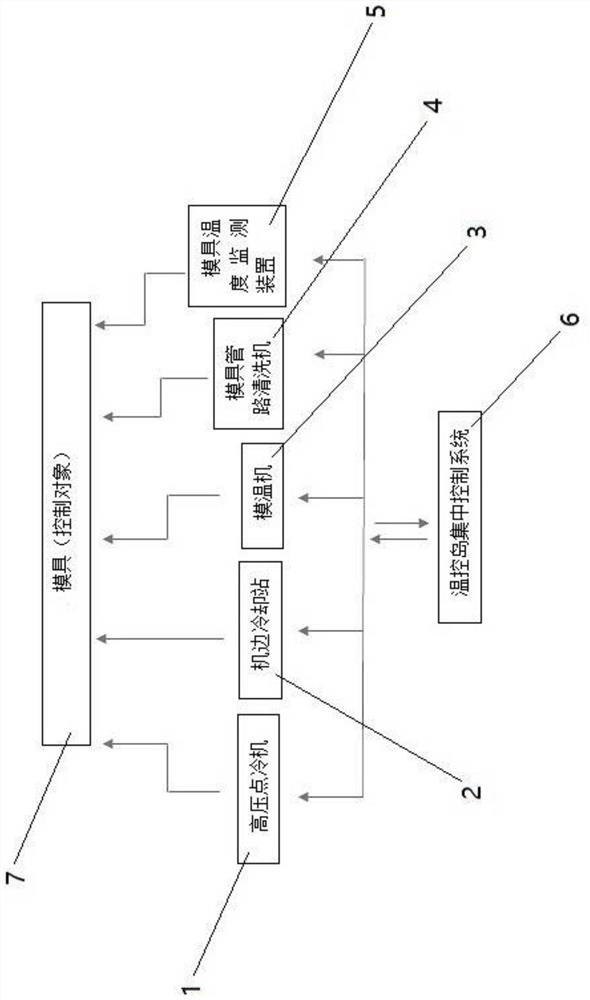

[0021] Such as figure 1 As shown, a temperature control island based on die-casting production molds to realize intelligent control includes a high-pressure point cooler 1, a side cooling station 2, a mold temperature controller 3, a mold pipeline cleaning machine 4, a mold temperature monitoring device 5, and a temperature control Island centralized control system 6 and mold 7, high-pressure point cooler 1, machine side cooling station 2, mold temperature controller 3 are connected to mold 7 through pipelines, mold temperature monitoring device 5 is installed on the side of mold 7, mold pipeline cleaning machine 4 It is connected to the mold 7 through pipelines, and the temperature control island centralized control system 6 is used to collect data from the high-pressure point cooler 1, machine side cooling station 2, mold temperature controller 3, mold pipeline cleaning machine 4 and mold temperature monitoring device 5.

[0022] Preferably, the mold temperature monitoring d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com