Quick die-filling device and method for sectioning type multi-layer partition plate

A multi-layer clapboard and split-type technology, which is applied in the field of split-type multi-layer clapboard quick-loading devices, can solve the problems of cumbersome operation, inconvenient actual operation, complex structure, etc., and achieves simple operation, complete appearance, and simplification. The effect of the moulding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Combine below Figure 2~6 The embodiments of the present invention will be described in detail.

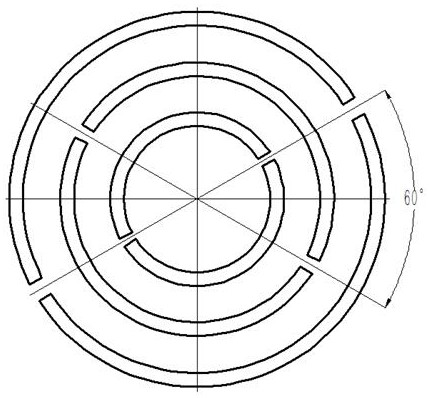

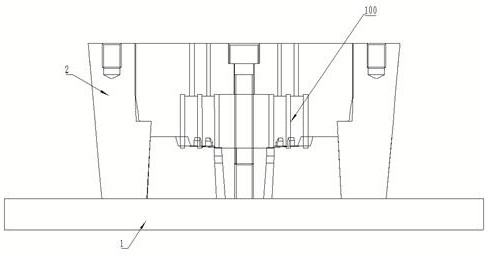

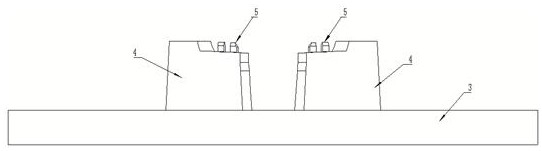

[0028] The split type multi-layer baffle quick-loading device is characterized in that it includes a base assembly 1 for layering and positioning the baffle and an insert assembly 2 which is provided with a flow channel and can be matched with the mold cavity of the product. The radial layers are placed on the base assembly 1 to form circumferential and radial positioning, the gaps of the adjacent layers of the partitions are separated by the base assembly 1 according to a preset angle in the circumferential direction, and the insert assembly 2 is placed on the upper edge of the base assembly 1. Axial clamping diaphragm.

[0029] In the above-mentioned split-type multi-layer baffle fast mold loading device, the baffles 100 are placed on the base assembly 1 in layers in the radial direction to form circumferential and radial positioning, and the gaps between the adjacent la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com