Sand washing boat dual-shaft dewatering screen and method

A dewatering screen and sand washing technology, which is applied in the field of dewatering screens, can solve the problems of low dehydration capacity, low processing capacity, and low screening efficiency, and achieve the effects of increasing water flow, large filtering area, and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

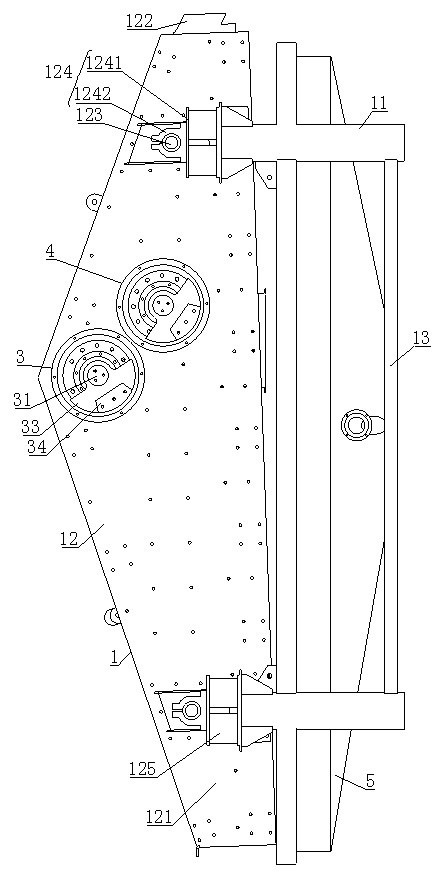

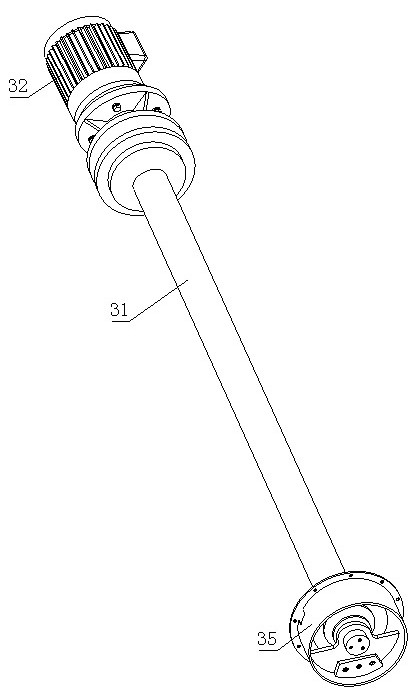

[0032] refer to Figure 1 to Figure 2 , a double-shaft dewatering screen for a sand washing ship, comprising a dewatering screen frame 1, a dewatering screen 2, a first driving shaft assembly 3, a second driving shaft assembly 4 and a water tank 5, and a dewatering screen is installed in the middle of the dewatering screen frame 1 2. The mesh number of the dehydration screen 2 gradually increases from the inlet 121 to the outlet 122. The unique design of the dehydration screen 2 is adopted, and the mesh number of the dehydration screen 2 at the inlet 121 is small, which improves the water flow. Throughput, the dehydration screen 2 at the discharge port 122 has a larger mesh number, finely screens a small amount of water content in the sediment, improves the screening efficiency, and has a large filtration area. The top of the screen 2 is provided with a first drive shaft assembly 3 and a second drive shaft assembly 4, and the dehydration screen frame 1 includes a support colum...

Embodiment 2

[0039] refer to Figure 1 to Figure 2 , a double-shaft dewatering screen for a sand washing ship, comprising a dewatering screen frame 1, a dewatering screen 2, a first driving shaft assembly 3, a second driving shaft assembly 4 and a water tank 5, and a dewatering screen is installed in the middle of the dewatering screen frame 1 2. The mesh number of the dehydration screen 2 gradually increases from the inlet 121 to the outlet 122. The unique design of the dehydration screen 2 is adopted, and the mesh number of the dehydration screen 2 at the inlet 121 is small, which improves the water flow. Throughput, the dehydration screen 2 at the discharge port 122 has a larger mesh number, finely screens a small amount of water content in the sediment, improves the screening efficiency, and has a large filtration area. The top of the screen 2 is provided with a first drive shaft assembly 3 and a second drive shaft assembly 4, and the dehydration screen frame 1 includes a support colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com