Circulating paint spraying line

A paint spraying line and conveying line technology, which is applied in the spraying room, spraying device, liquid spraying device, etc., can solve the problems of wasting manpower, unable to ensure the uniform thickness of workpiece paint, physical harm to operators, etc., and achieve the effect of compact structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

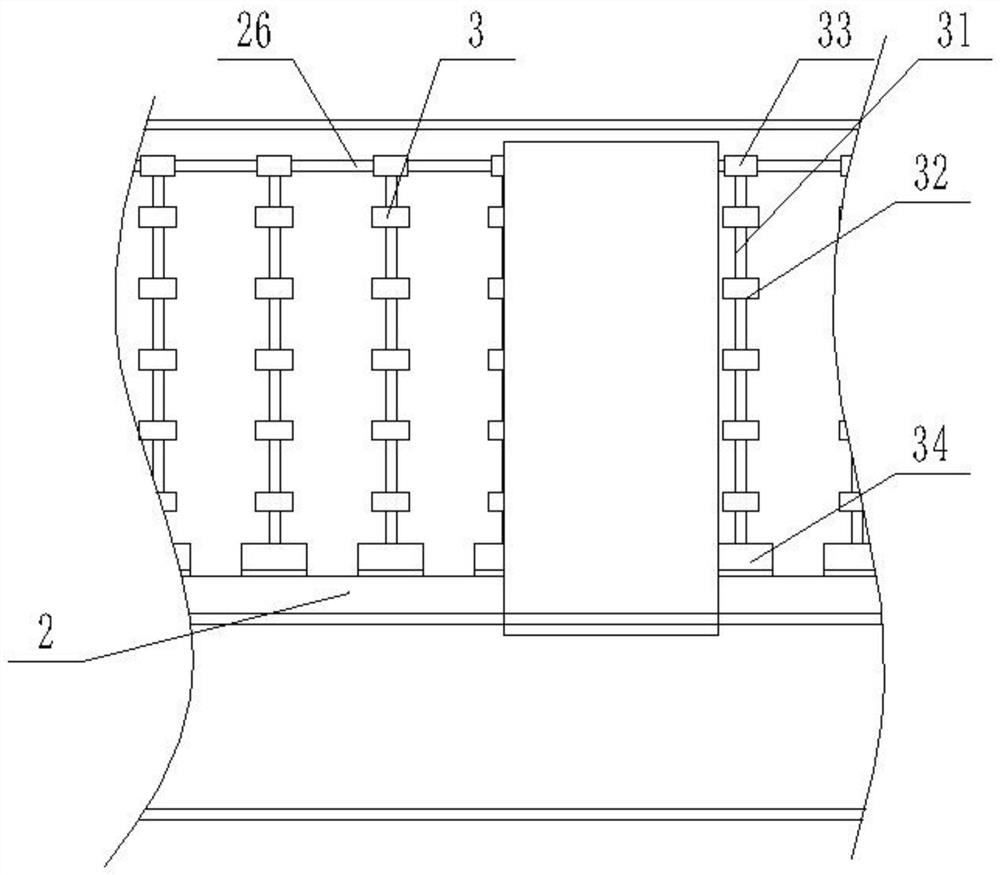

[0024] see Figure 1-4 , a circulating painting line, including a work room 1, a conveying line 2, a spraying device 4 and an air supply device 5,

[0025] The working room 1 is in the shape of a rounded rectangular ring as a whole, and the conveying line 2 is located inside the working room 1. The conveying line 2 includes two parallel conveying rails 21 and a conveying chain 22 running in the conveying rails 21. , the transmission chain 22 is provided with a plurality of positioning sockets 23, the positioning sockets 23 are provided with positioning holes, and the conveying line 2 also includes a transmission rod 25 for carrying objects to be sprayed and a conveying gear 24 to support the objects to be sprayed. The number of transmission rods 25 is half of the positioning sleeve 23, and the two ends of the transmission rod 25 are sleeved in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com