Precipitated sludge cleaning device for sewage treatment

A sewage treatment and cleaning device technology, which is applied to the feeding/discharging device of the settling tank, sedimentation separation, settling tank, etc., which can solve the problems of affecting the use efficiency of the settling tank and the inability to use the settled sludge in the settling tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

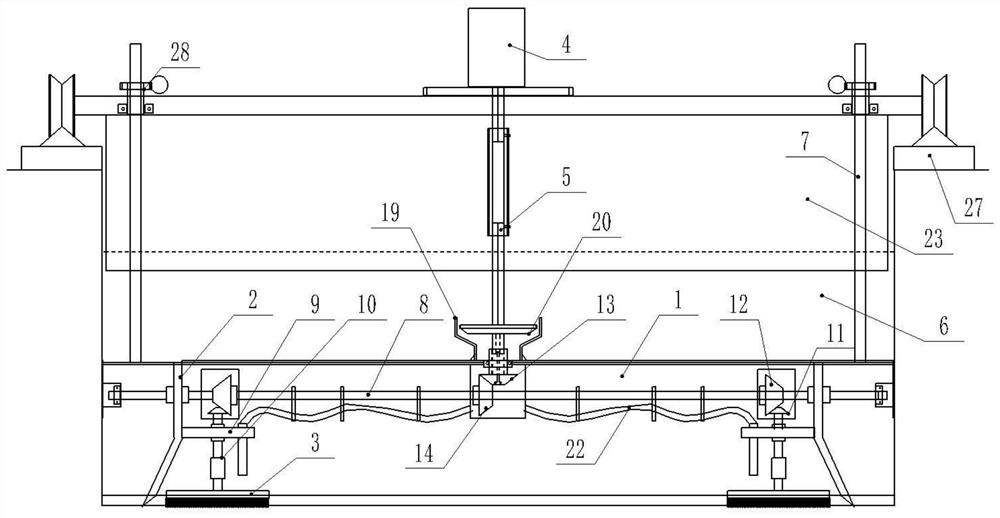

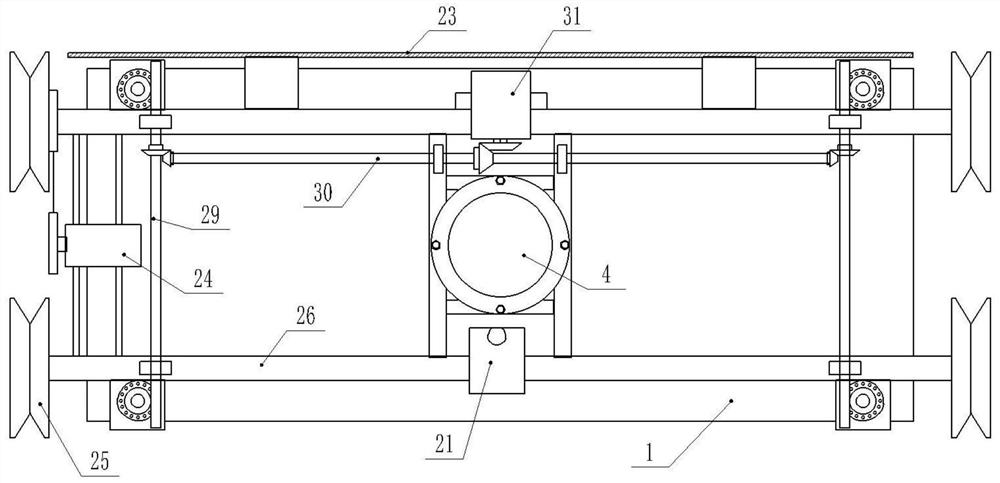

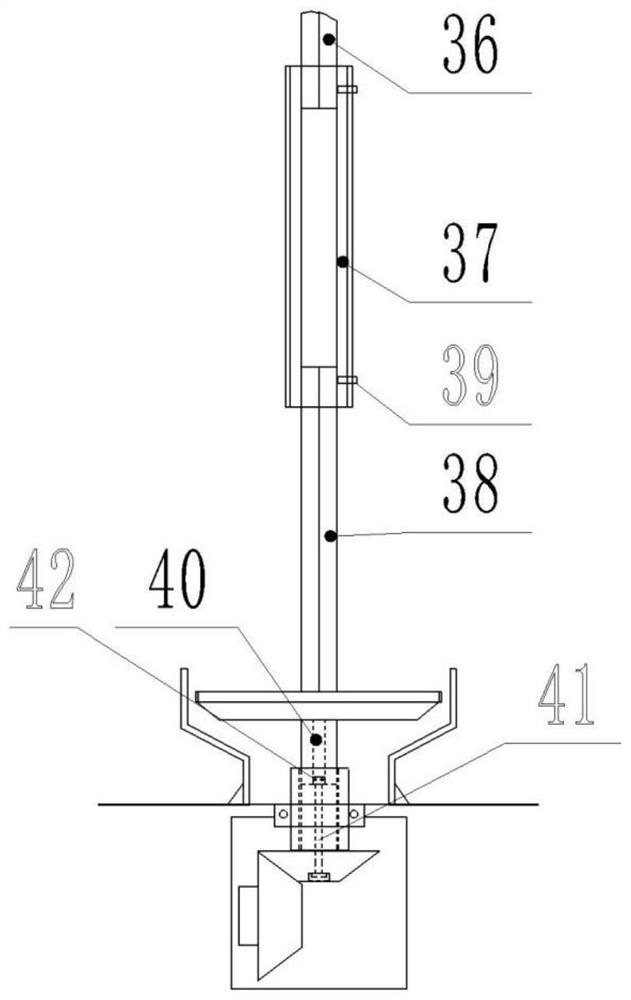

[0039] like Figure 1-8 As shown, a kind of sedimentation sludge cleaning device for sewage treatment of the present invention comprises a walking frame device, a U-shaped buckle cover 1, a buckle cover lifting device, a mud scraper 2, an agitating brush 3 and a mud scraper drive motor 4. The walking frame device is erected above the sedimentation tank 6, the cover lifting device is arranged on the walking frame device, and the four lifting screw rods 7 of the cover lifting device are connected to the U-shaped cover 1, and the U-shaped cover is controlled by the cover lifting device. The U-shaped button cover 1 is lifted; the U-shaped button cover 1 is made of stainless steel plate with a U-shaped structure. The height of the U-shaped button cover 1 is generally set according to the thickness of the sedimentation mud in the sedimentation tank 6. The sedimentation tank 6 mud in the block area is all sealed, and the amount of sewage is reduced as much as possible, and the water ...

Embodiment 2

[0048] like Figure 1-8 As shown, the present invention is a settling sludge cleaning device for sewage treatment. On the basis of Embodiment 1, this embodiment adds the function of cleaning scum, and a scum baffle is hung on one side of the walking frame device 23. The scum baffle 23 is attached to one side of the outer wall of the U-shaped button cover 1 . The scum baffle 23 is inserted in the sewage to isolate the scum on one side, so that when the U-shaped button cover 1 descends into the sewage, the scum collected on one side of the scum baffle 23 will be covered on the U-shaped button cover 1 Inside, when the sludge is subsequently sucked, the scum is sucked and removed together with the sludge, and the walking frame device continuously drives the scum baffle 23 to move in one direction of the sedimentation tank 6, so that the scum will be continuously covered by the U-shaped button 1 is covered and subsequently drawn away, and a filter screen is provided on the lower w...

Embodiment 3

[0050] like Figure 1-8As shown, the present invention is a settling sludge cleaning device for sewage treatment. On the basis of the above-mentioned embodiments, the walking frame device includes a walking motor 24, a pulley 25 and a support shaft 26, which are placed on the edge of the sedimentation tank 6 Guide rails 27 are laid, at least two support shafts 26 are erected on the sedimentation tank 6, pulleys 25 are provided at both ends of the support shafts 26, and the pulleys 25 are slidably arranged on the guide rails 27, and the support shafts 26 are connected and fixed by connecting rods. The traveling motor 24 is connected to at least one pulley 25 through a transmission chain, and the traveling frame device is driven by the traveling motor 24 to move on the guide rail 27 . Walking frame device is exactly a support walking frame, controls walking frame to move on setting guide rail 27 by controlling traveling motor 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com