Clamp for plate compression-shear fracture analysis sample, method thereof and sample

A technology for analyzing samples and fracture tests, which is applied in the direction of analyzing materials, testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, etc., to reduce the compression deformation of sheet metal and change the loading angle , Processing and production convenient and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

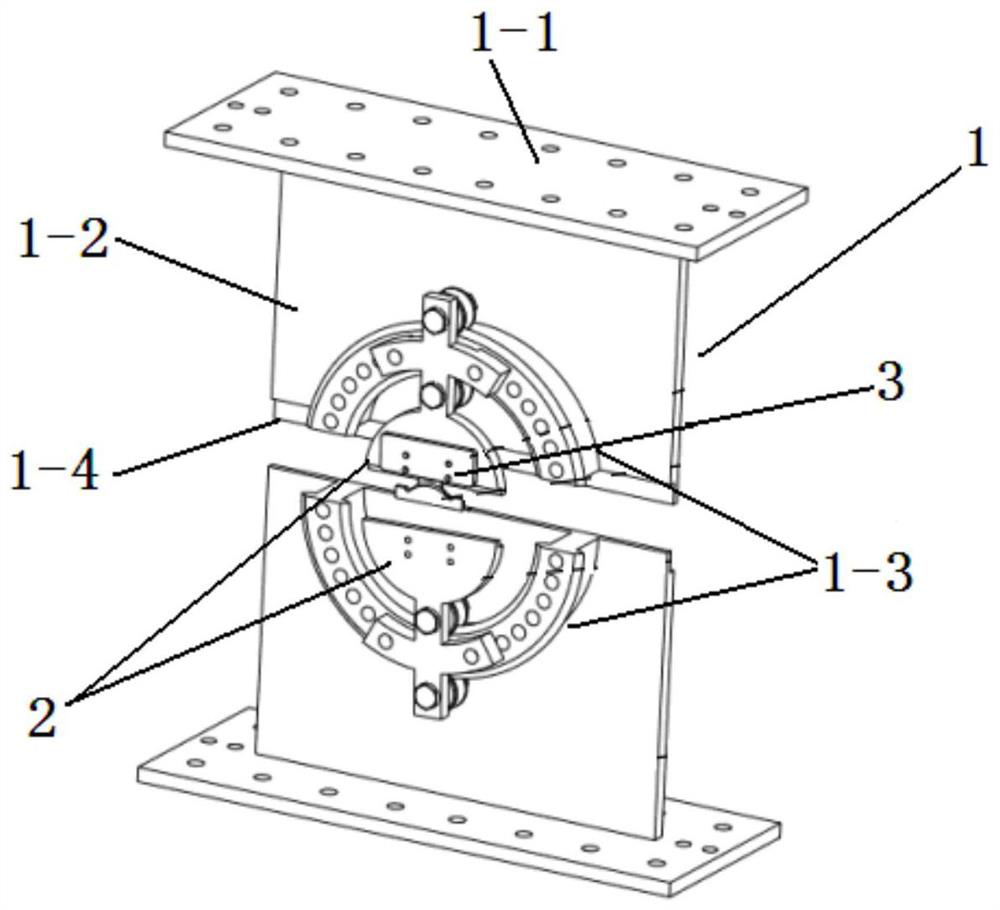

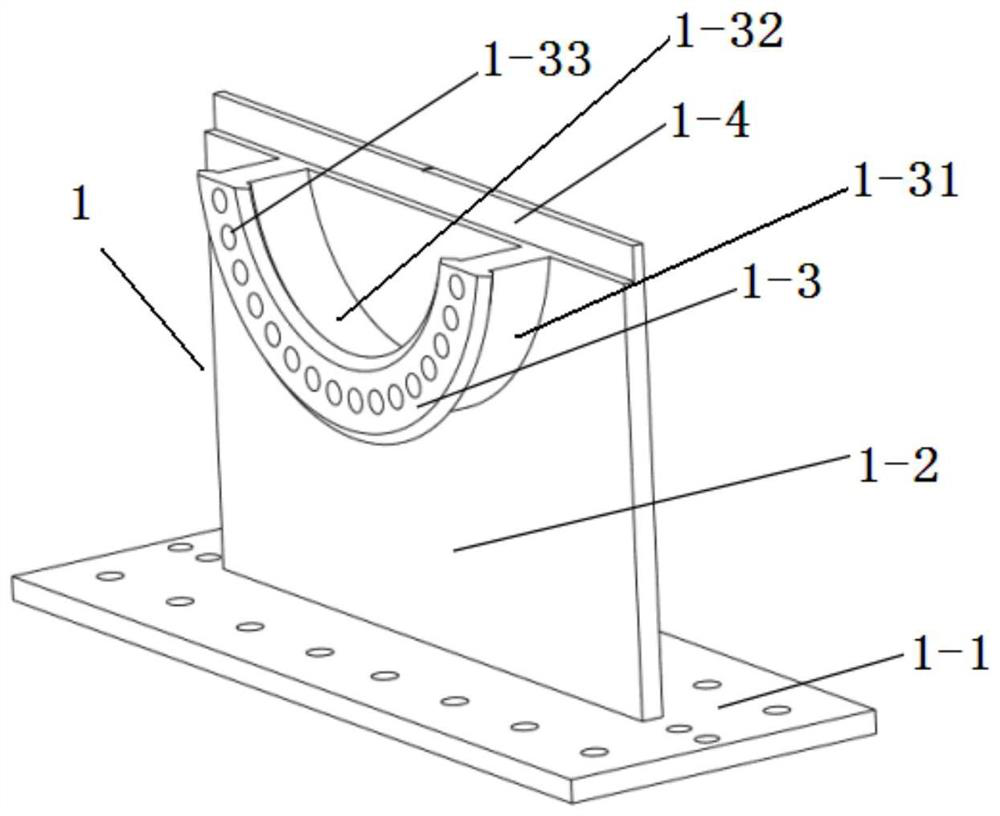

[0042] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0043] like figure 1 As shown, the present invention is a clamp for a sample for plate compression-shear fracture analysis, and the clamp includes;

[0044] The bottom plate 1 is used to install the rear splint 2 and connect the testing machine to the rear splint 2;

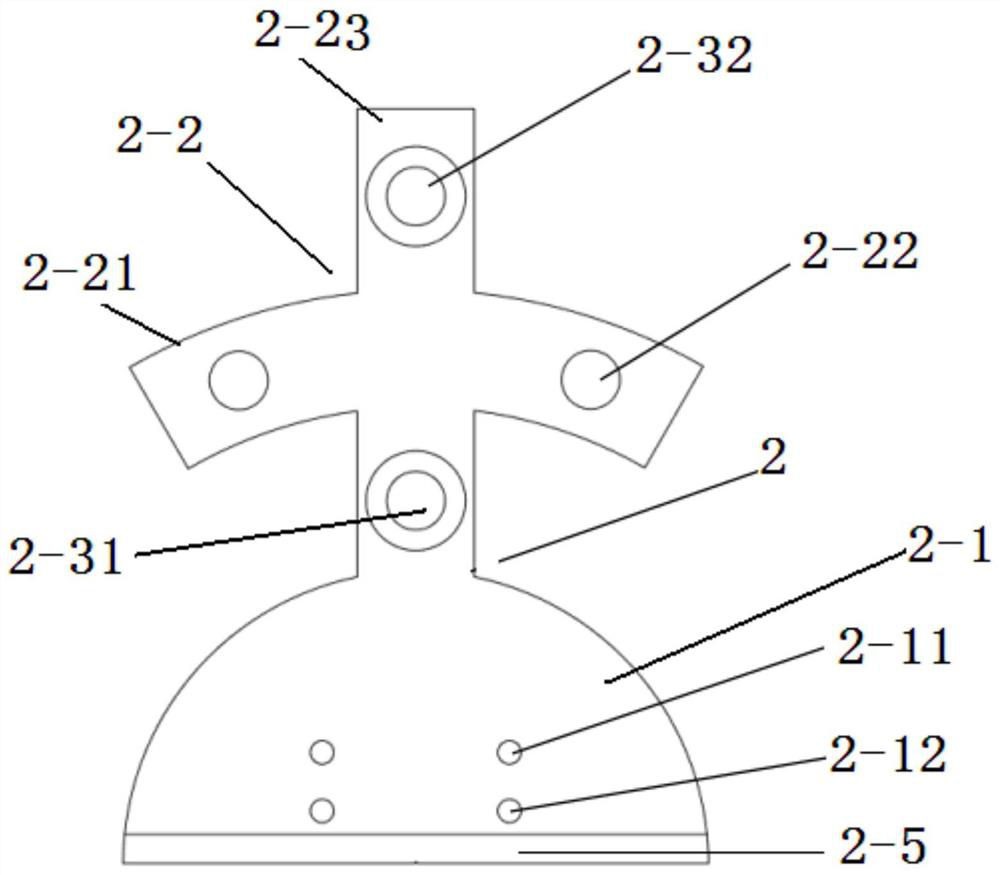

[0045] The rear splint 2 is used to adjust the force angle of the applied force on the sample according to the test requirements;

[0046] The front splint 3 is used to stably fix the sample 5 between the rear splints, so that the force acts on both ends of the sample 5 evenly;

[0047] Wherein, the bottom plate includes an upper bottom plate and a lower bottom plate; the two rear clamping plates are symmetrically arranged at the ends of the upper and lower bottom plates, respectively, and the two front clamping plates are symmetrically arranged at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com