Long flow plate heat exchanger

A technology of plate heat exchanger and long process, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of restricting the popularization and application of heat exchangers, and the inability to effectively collect condensate, so as to achieve the benefit of The effect of integrated installation and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings. The embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

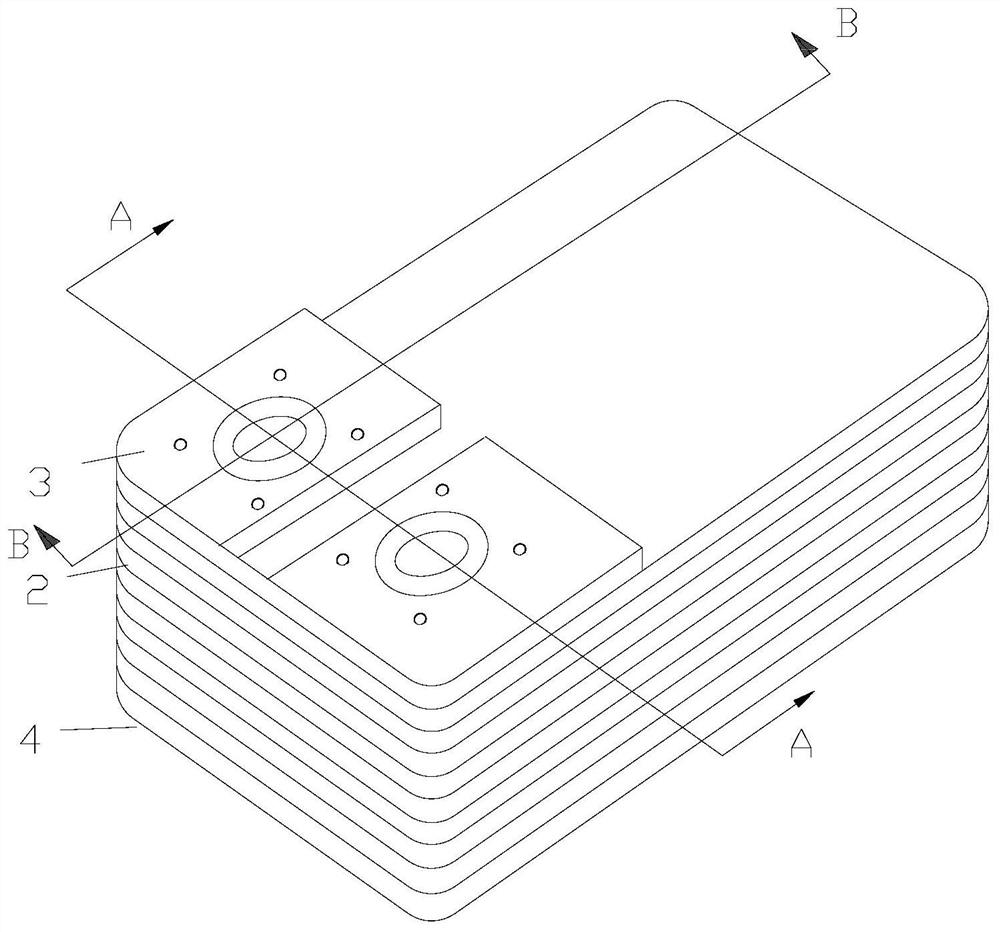

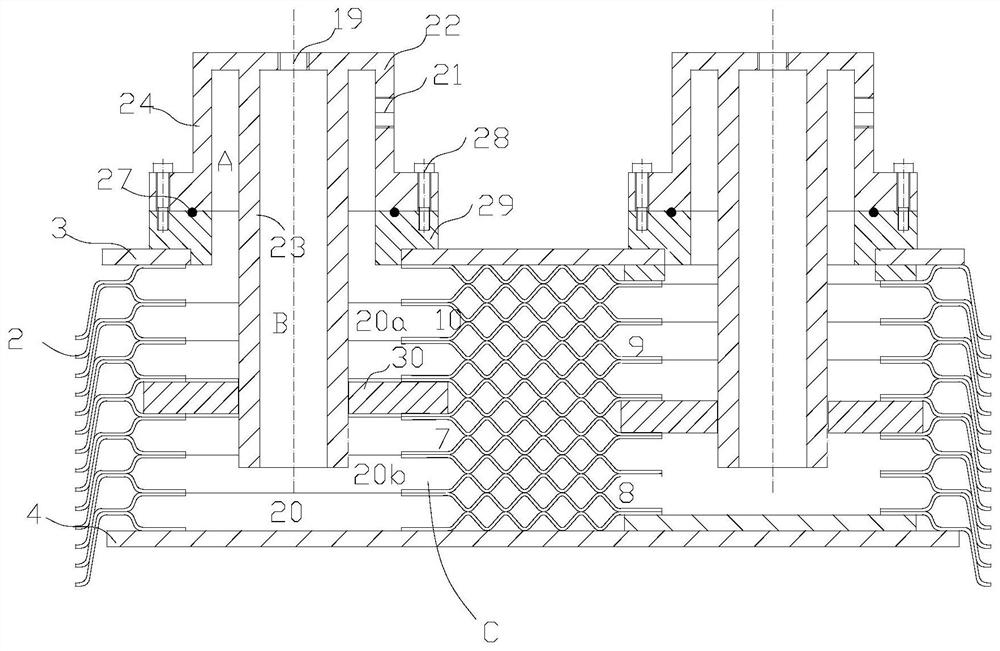

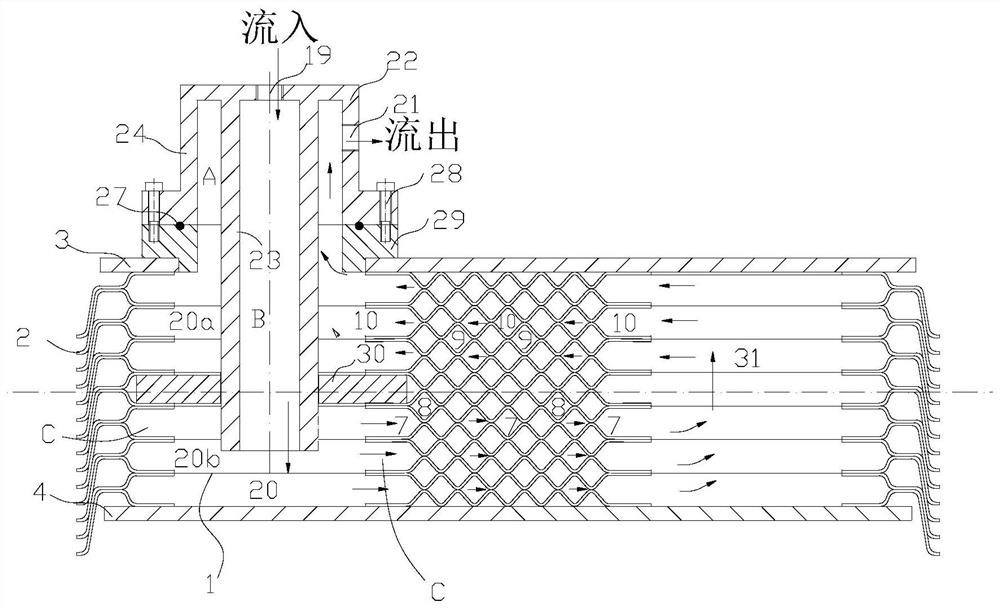

[0030] The plate heat exchanger of this embodiment includes an upper end plate 3, a lower end plate 4, and a series of heat exchange plates 2 neatly laminated between the upper and lower end plates, and a heat exchange flow layer is formed between adjacent heat exchange plates 2, which are relatively Adjacent heat exchange fluid layers do not interfere with each other, and the heat exchange fluid layers through which two heat exchange fluids flow are arranged alternately up and down, that is, all heat exchange fluid layers serving the same heat exchange fluid are arranged at intervals. Furthermore, each heat exchange plate 2 includes a flanging, a heat exchanging area and four corner holes 1, and through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com