Supercritical carbon dioxide coal-fired boiler system and its flue-air coupling three-dimensional circulation process

A carbon dioxide, coal-fired boiler technology, applied in the direction of non-flammable liquid/gas transportation, combustion chamber, combustion type, etc., can solve the problem of protecting supercritical carbon dioxide boilers prone to over-temperature areas and supercritical carbon dioxide boiler furnaces in a large range. Problems such as increased wall temperature and difficulty in controlling the air volume attached to the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

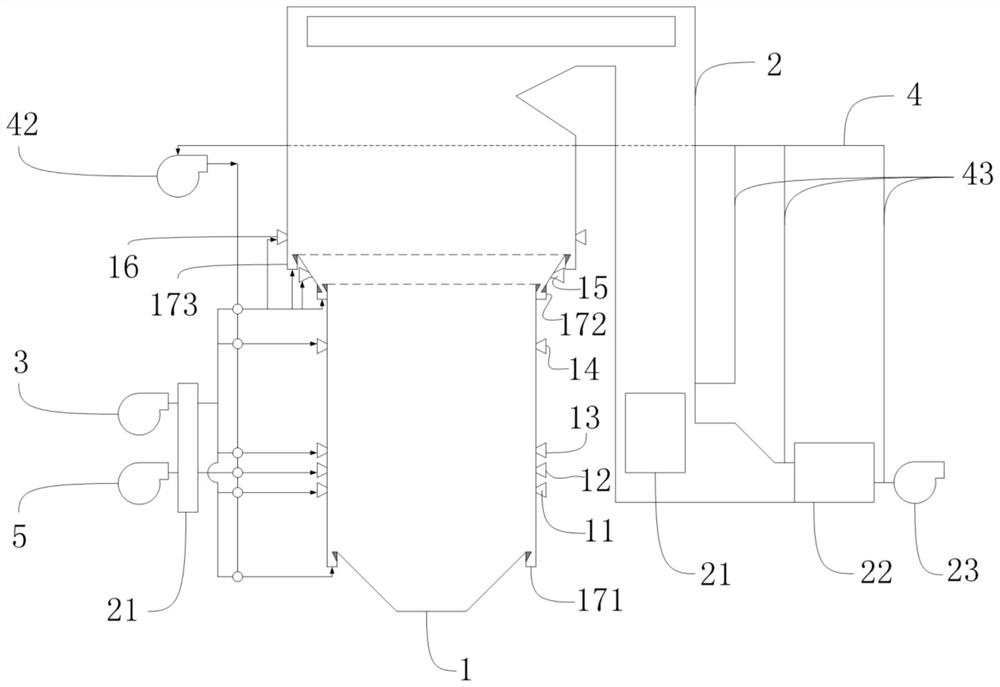

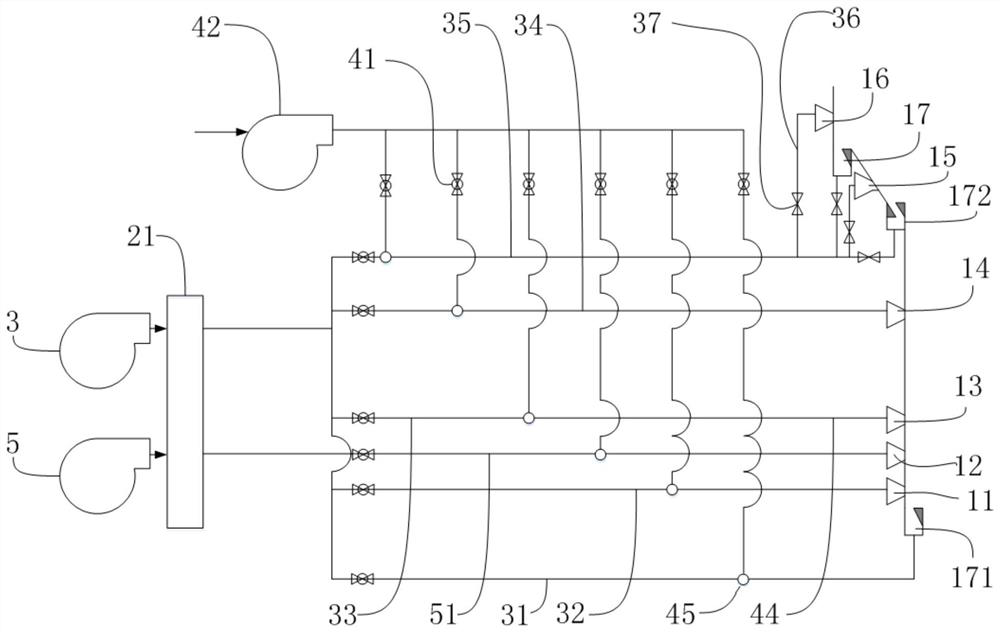

[0078] The supercritical carbon dioxide coal-fired boiler described in this embodiment adopts a Π-type furnace, and the furnace of the Π-type furnace includes a small furnace section, an intermediate transition section and a large furnace section sequentially connected from bottom to top, and the diameter of the large furnace section is a small furnace 1.2 times that of the section, the middle transition section is a truncated cone, the cross-sectional area of the middle transition section gradually increases from bottom to top, and the angle between the side wall and the horizontal plane is 45°, and the small furnace section is equipped with The lower combined air nozzle, the connection between the small furnace section and the middle transition section is provided with a middle combined air nozzle, and the connection between the middle transition section and the large furnace section is provided with an upper combined air nozzle.

[0079] The small furnace section is provid...

Embodiment 2

[0082] Different from Example 1, the supercritical carbon dioxide coal-fired boiler mixes 50% of the recirculation flue gas flowing through the recirculation fan with the SOFA wind under the condition of 70% THA, and 50% of the recirculation flue gas is mixed with the SOFA wind. Primary wind, secondary wind and OFA wind are mixed. Among them, the air volume ejected from the upper combined air nozzle 173 is 5% of the sum of the primary air, secondary air, and recirculated flue gas air volume, and the air volume ejected from the middle combined air nozzle 172 is 5% of the primary air, secondary air, and recirculated smoke. 10% of the sum of air volume, and the air volume ejected from the lower combined air nozzle 171 accounts for 20% of the sum of primary air, secondary air, and recirculation flue gas air volume, measuring the small furnace section, intermediate transition section and large furnace section of the boiler The maximum wall temperature, which measures the boiler com...

Embodiment 3

[0084] Different from Example 1, the supercritical carbon dioxide coal-fired boiler mixes 60% of the recirculation flue gas flowing through the recirculation fan with the SOFA wind under the 45% THA working condition, and 40% of the recirculation flue gas is mixed with the SOFA wind. Primary wind, secondary wind and OFA wind are mixed. Among them, the air volume ejected from the upper combined air nozzle 173 is 5% of the sum of the primary air, secondary air, and recirculated flue gas air volume, and the air volume ejected from the middle combined air nozzle 172 is 5% of the primary air, secondary air, and recirculated smoke. 5% of the sum of air volume, and the air volume ejected from the lower combined air nozzle 171 accounts for 15% of the sum of primary air, secondary air, and recirculation flue gas air volume, measuring the small furnace section, intermediate transition section and large furnace section of the boiler The maximum wall temperature, which measures the boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com