A chemical control method during the flushing of the secondary loop during start-up of a nuclear power plant

A chemical control, secondary circuit technology, applied in chemical instruments and methods, nuclear power plants, boiler cleaning control devices, etc., can solve the problems of increasing the flushing time, increasing the consumption of flushing water, and the impact of the flushing construction period, and reducing consumption and effect. Significant, well-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

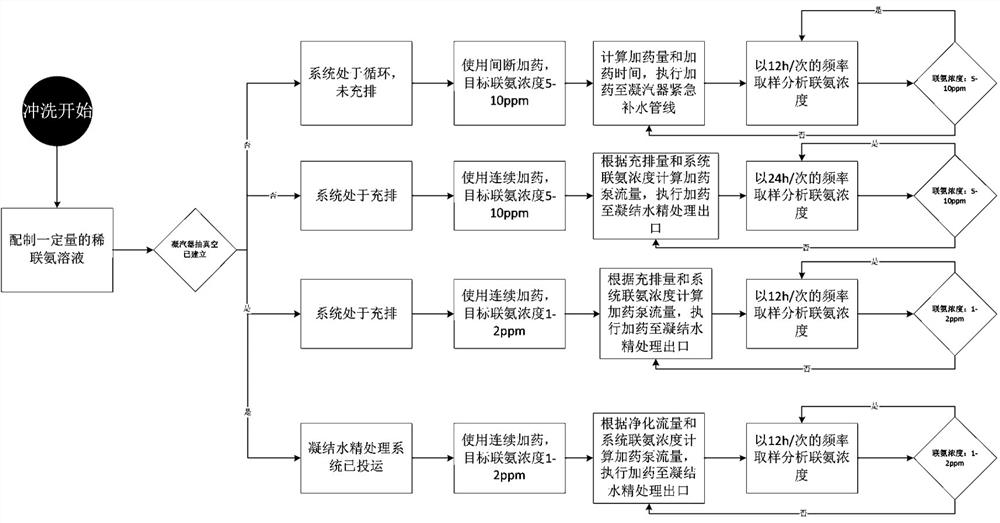

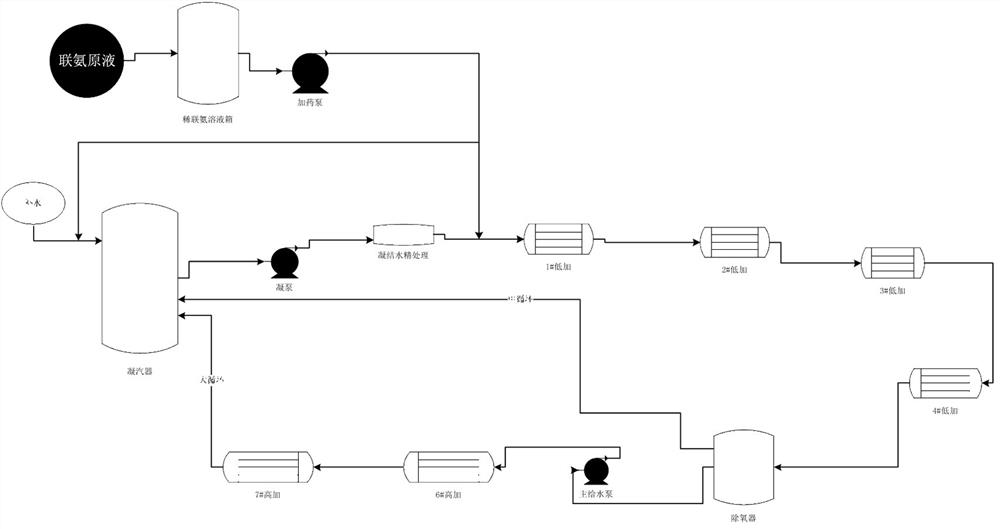

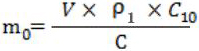

[0100] The specific process of the chemical control method adopted by the present invention is as attached figure 1 As shown, the device of the secondary circuit flushing system is as attached figure 2 As shown, and the chemical control method was carried out in the flushing stage, and the following data indicators were obtained:

[0101] (1) After the No. 1 unit was loaded, the chemical control method was used during the flushing period. After more than ten days of commercial operation, the sewage quality reached the median value of WANO-CPI, which was the fastest record for domestic counterparts;

[0102] (2) After the 101 overhaul was started, the chemical control method was used during the flushing period, and the sewage quality was kept below the median level of WANO-CPI, while the peer power station needed about 7 days of purification time to reach the standard after full power;

[0103] (3) After the No. 2 machine was loaded, the chemical control method was used durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com