Production line and forming method for forming cement-based composite river silt multilayer board

A technology of river silt and multi-layer boards, applied in the direction of layered products, ceramic molding machines, molding conveyors, etc., can solve the problems of difficult production of cement boards, difficult multi-layer board production, low production efficiency, etc., to reduce boards Effect of increasing density, increasing strength, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

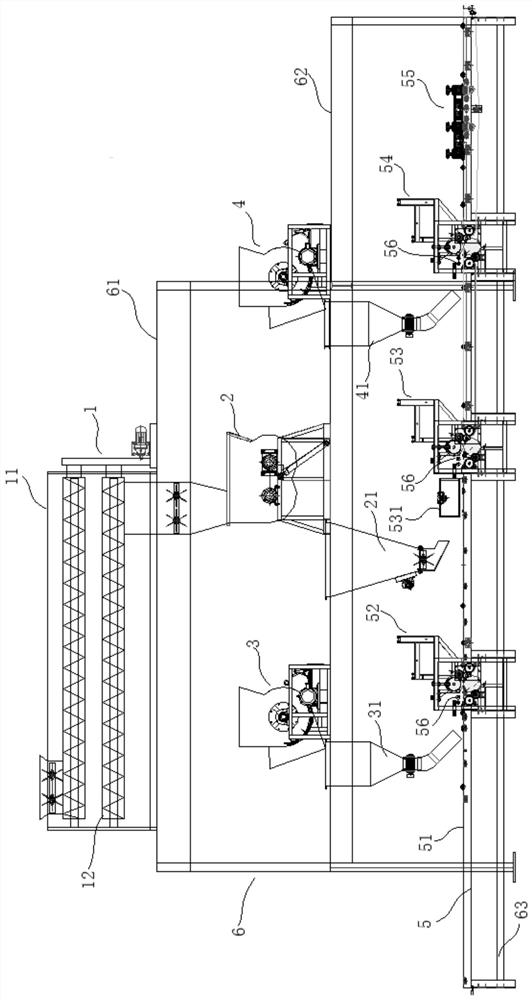

[0042] Such as figure 1 A production line for forming cement-based composite river silt multi-layer boards is shown, including three-layer mounting frame, microwave processing equipment, core material mixer, first fabric mixer, second fabric mixer, core material hopper, first fabric hopper, Second fabric hopper and conveying and laying equipment;

[0043] The layer installation frame includes the first installation platform, the second installation platform and the third installation platform arranged in sequence from top to bottom; the microwave processing equipment is installed on the first installation platform; the core material mixer, the first fabric mixer and the second fabric mixer are all installed on the second installation platform; the feed ports of the core material hopper, the first fabric hopper and the second fabric hopper are all installed on the second installation platform; the conveying and laying equipment is installed on the third installation platform, a...

Embodiment 2

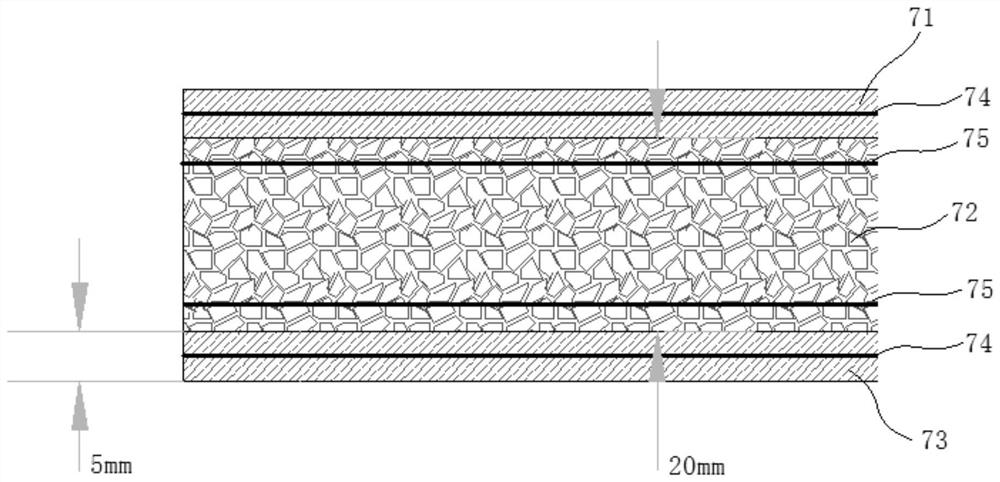

[0048] On the basis of Example 1, the following improvements have been further made: the feeding ends of the first pressing material spreading equipment, the second pressing material spreading equipment and the third pressing material spreading equipment are respectively provided with two vibrating rods, Each diameter is 20mm, the vibration amplitude is 20mm, and the vibration frequency is 150 times / minute, which helps the material flow evenly.

Embodiment 3

[0050] On the basis of Example 2, further improvements are made as follows: a leveling device is provided upstream of the second pressing and spreading device, and the feed end of the second pressing and spreading device is arranged upstream of the leveling device. Because the thickness of the core material layer is relatively thick, a screw leveling device is arranged upstream of the second pressing and spreading equipment.

[0051] Utilize above-mentioned production line, prepare cement-based composite river silt multi-layer board, comprise the following steps:

[0052] 1) Add cement (Albo 525 white cement) and water with a mass ratio of 3.33:1 to both the first fabric mixer and the second fabric mixer, and stir. The mixing speeds of the first fabric mixer and the second fabric mixer are both 350 revs / min, the single mixing time (stirring time of one feeding) of the first fabric mixer and the second fabric mixer is 4 minutes, gets cement mixture;

[0053] 2) Add river silt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com