Microporous activated carbon for urea adsorption and preparation method and application thereof

A kind of activated carbon preparation and activated carbon technology, which is applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems that cannot meet the needs of actual use, low urea adsorption capacity, etc., to simplify development and improve adsorption performance , solve the effect of low urea capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example provides activated carbon and its preparation: KOH and 80-120 mesh coconut shell carbonized material are mixed evenly according to the mass ratio of 1.5, then placed in a tube furnace, heated to 850°C under a nitrogen atmosphere, and heated to 850°C according to the set time of 2.5 h keep warm. After cooling, wash away soluble matter with deionized water, place the obtained solid in 1M dilute hydrochloric acid, heat to 50°C, adjust to weakly acidic pH=6 or so, filter, wash with water until neutral, and store at 110°C After drying, activated carbon was obtained. The pore size parameters were characterized by BET analysis. The pore size parameters of the prepared activated carbon (KOH / C=1.5@850-2.5h) are shown in Table 1.

Embodiment 2

[0030] Using the same method as in Example 1, the difference is that the mass ratio of KOH to carbon material is 2, and the pore diameter parameters of the prepared activated carbon (KOH / C=2@850-2.5h) are shown in Table 1.

Embodiment 3

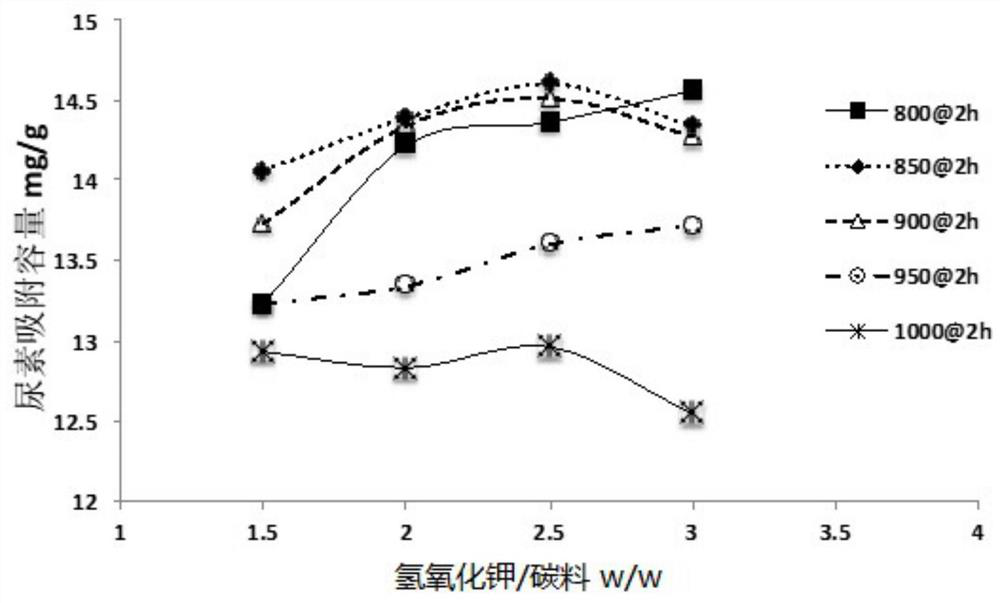

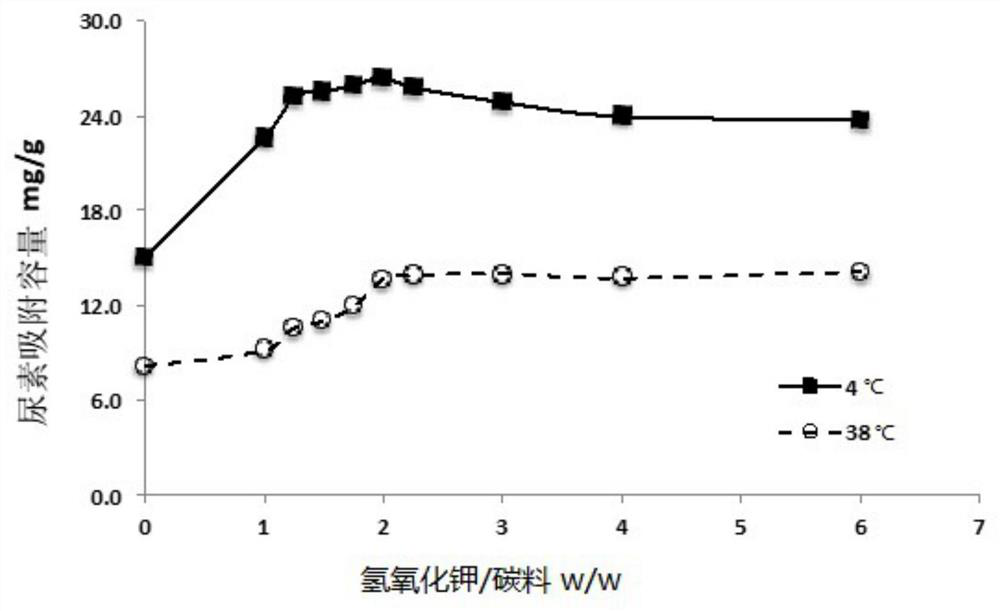

[0032] Using the same method as in Example 1, the difference is that KOH is replaced by CH 3 COOK, prepared activated carbon (CH 3 COOK / C=3@850-2.5h) See Table 1 for pore diameter parameters. The adsorption properties of activated carbon prepared under different conditions to urea are shown in Table 2 and figure 2 .

[0033] Table 1 comparative example and the aperture parameter of embodiment 1~3

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com