Extraction fitting for liquid containers

A technology for liquid containers and accessories, applied in the field of extraction accessories for liquid containers, to achieve the effect of increasing the contact surface and reducing the number of pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

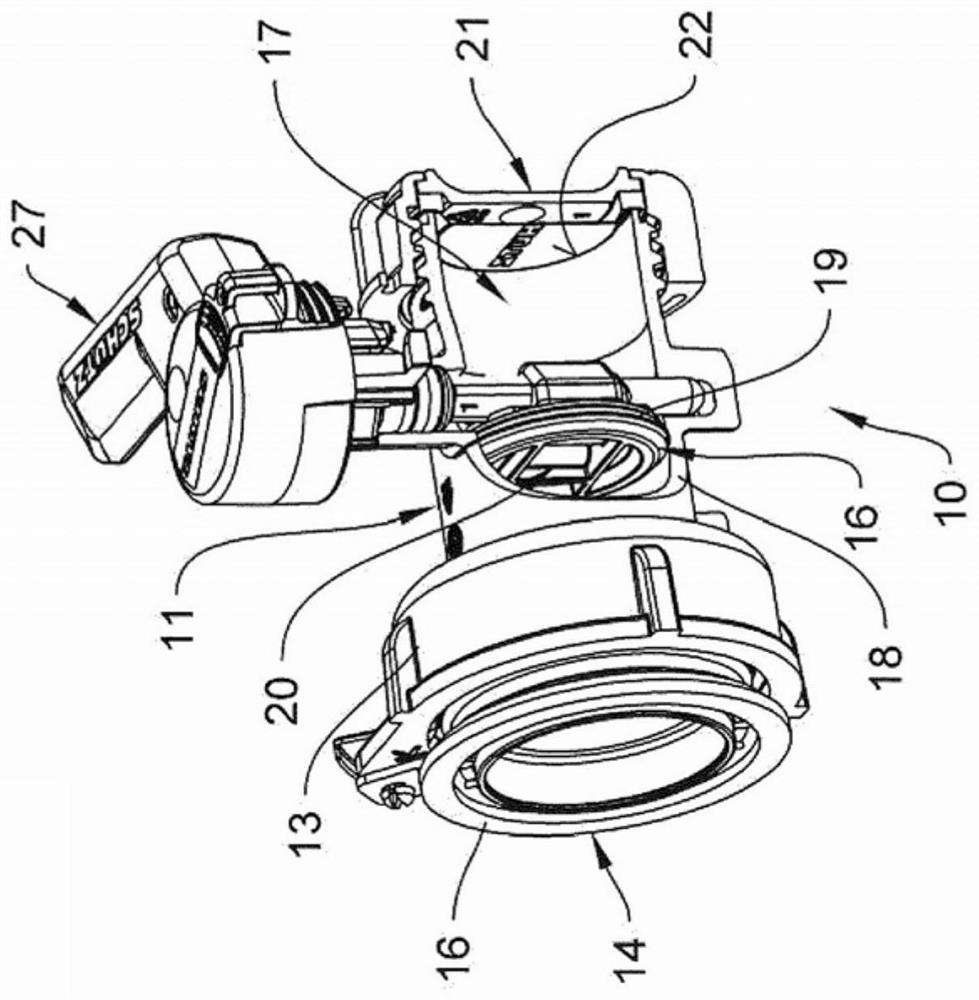

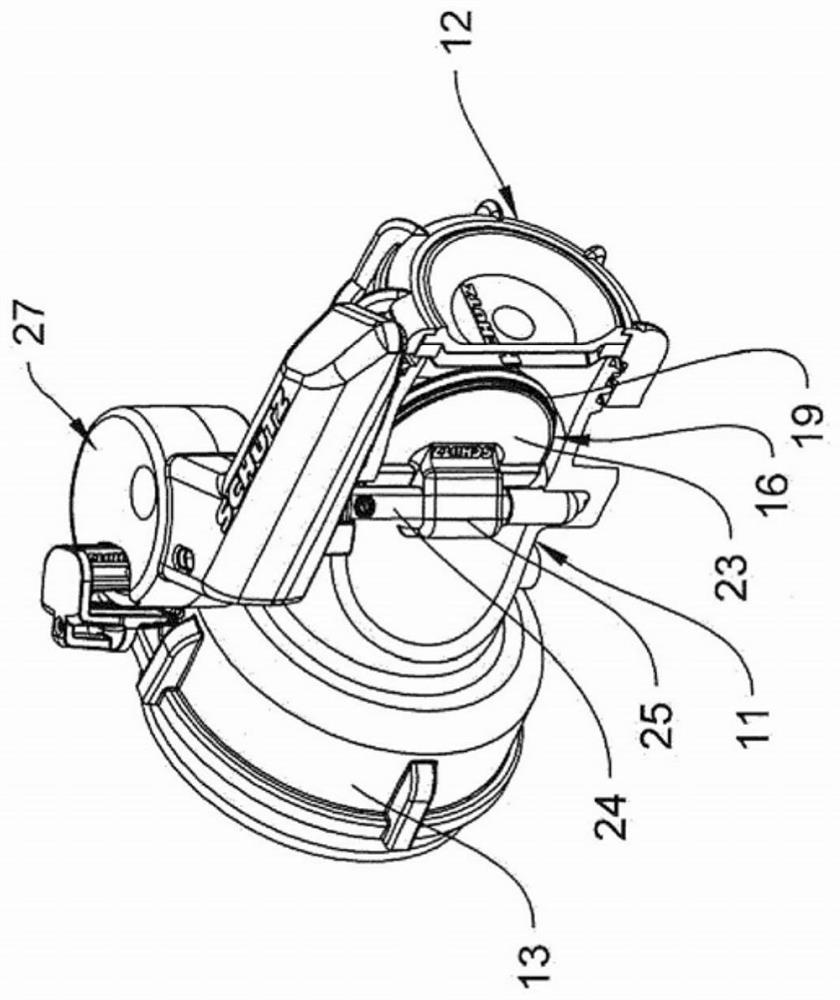

[0028] figure 1 The extraction fitting 10 is shown, which has a fitting housing 11 which is connected at the inflow end 12 by means of a union nut 13 to an outlet connection 14 which is arranged on a liquid container 15 ,exist figure 1 Only the accessory connection area is shown in . as in figure 1 A liquid container 15 of the type shown in is, for example, a container produced in blow molding, which is a component of an Intermediate Bulk Container (IBC) and is arranged as an inner container in a cage arranged on a pallet.

[0029] such as especially figure 2 As shown, in the case of the shown exemplary embodiment, the extraction fitting 10 is formed in combination with the outflow connection 14 formed independently of the liquid container 15 as an assembly unit, which can be connected to the liquid container 15 by means of Between the connection flange 16 of the outflow connection 14 formed as a welded connection and the outflow formed in the liquid container 15 figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com