Quality monitoring system for power cable production and manufacturing

A quality monitoring and power cable technology, which is applied in closed-circuit television systems, measuring electrical variables, signal transmission systems, etc., can solve the problems that the qualified rate of cable production cannot be further improved, cannot be supervised in an all-round way, and can reduce manual monitoring The effect of reducing costs, improving production safety, and improving production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

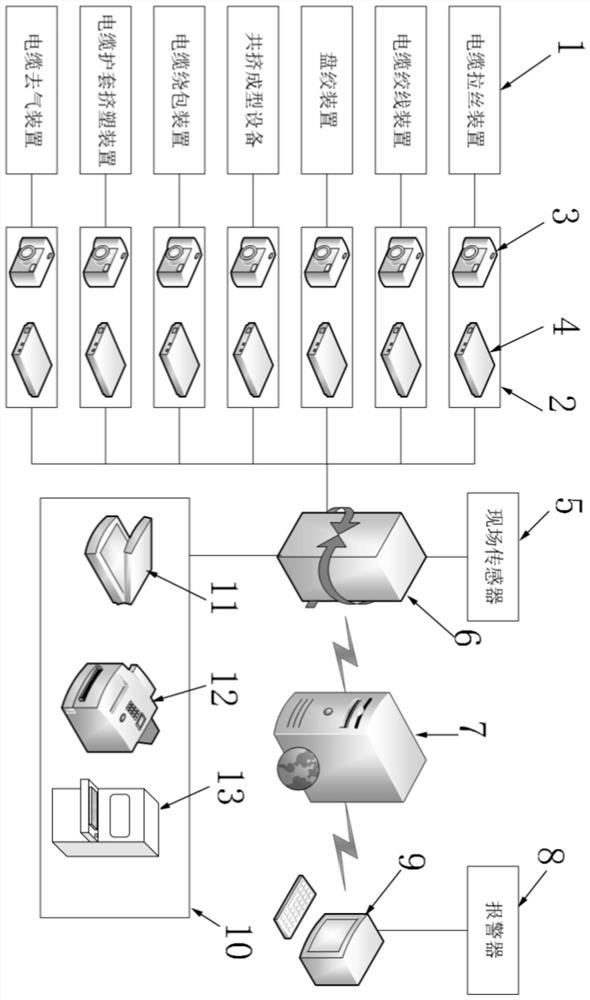

[0027] A quality monitoring system for power cable production and manufacturing, used for quality monitoring of cable production equipment 1, such as figure 1 As shown, the quality monitoring system includes a cable detection device, a cloud server 7, a field sensor 5 for obtaining production site environmental information, a wireless network module 6, an alarm 8, a control terminal 9 and multiple monitoring terminals 2. The cable production equipment 1, the cloud server 7 and the alarm 8 are connected to the control terminal 9, and the monitoring terminals 2 are respectively set at the cable production equipment 1.

[0028] During the power cable production process, the cable production equipment 1 is a cable drawing device, a cable stranding device, a twisting device, a co-extrusion molding device, a cable wrapping device, a cable sheath extrusion device, and a cable degassing device, which are arranged in sequence. The cable production equipment 1 of the invention is all co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com