Steel structure warping degree detection device

A detection device and warpage technology, applied in the direction of measuring devices, optical devices, measuring instruments, etc., can solve the problems of low detection accuracy, high requirements for the physical condition of inspectors, and inability to meet the detection of in-use equipment, and achieve expanded detection range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

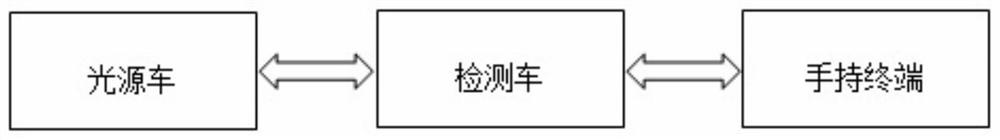

[0027] The principle of the steel structure warpage detection device of the present invention is as follows: figure 1 As shown, including light source vehicle, detection vehicle and handheld terminal,

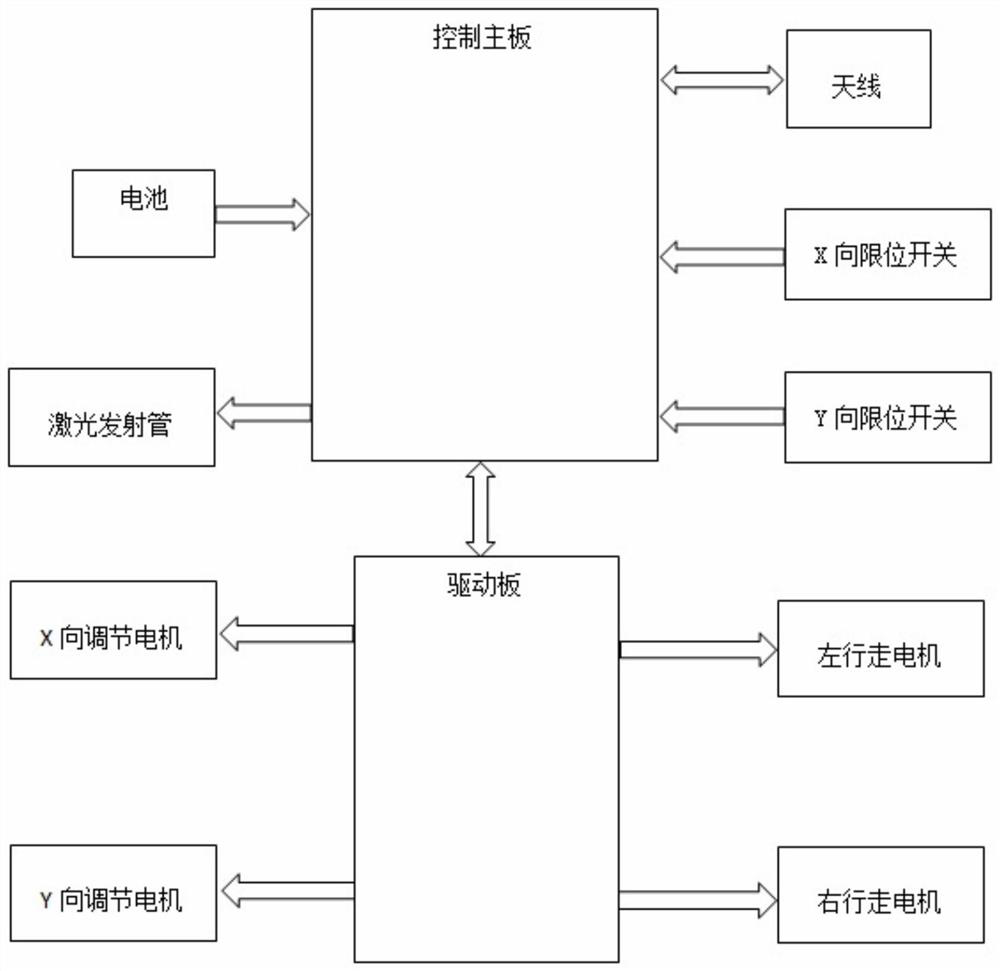

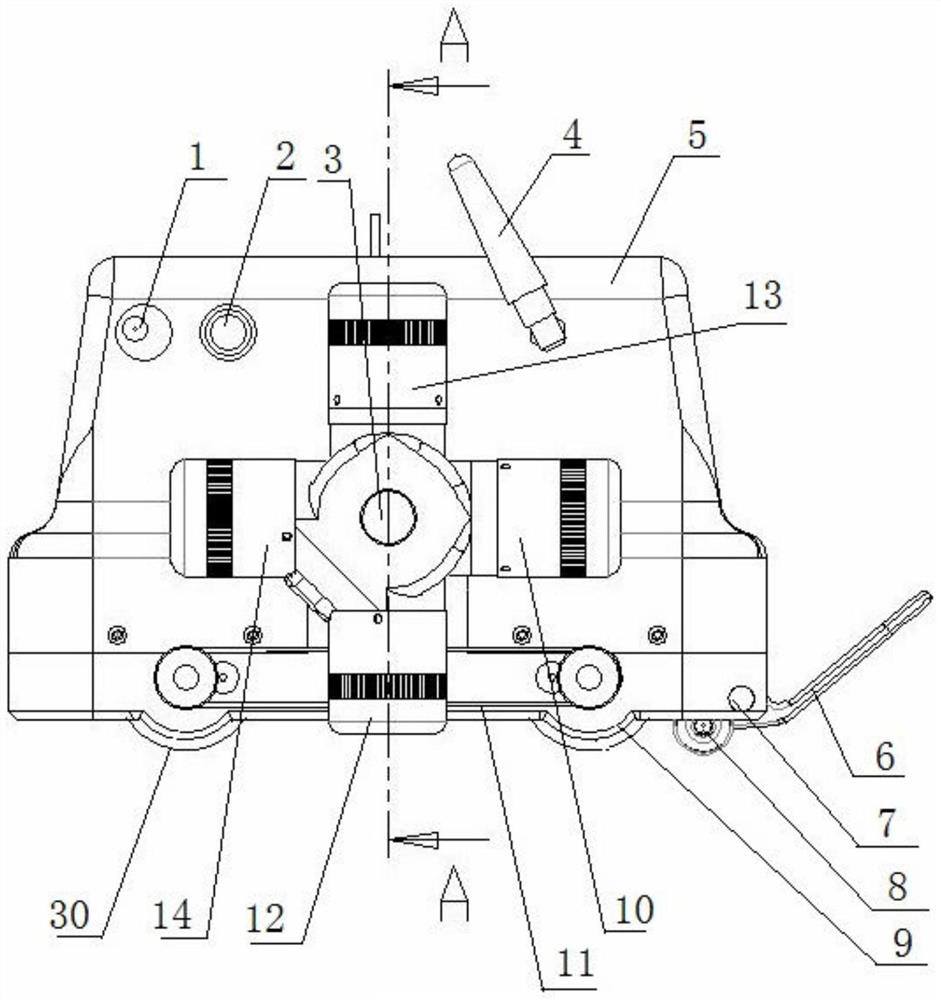

[0028] The hand-held terminal is electrically connected with the control board 39 of the detection vehicle. A laser tube 20 is installed in the laser tube sleeve fixing cavity 62 in the light source car, a laser emission port 3 is provided at the front of the light source car, a light source car control main board 60 is arranged in the light source car, and the light source car control main board 60 is connected to the laser tube 20; The light spot position sensor 32 is installed inside, and the detection car control board 39 is installed in the detection car, and the detection car control board 39 is connected to the light spot position sensor 32; the light source car control board 60 communicates with the detection car control board 39 through the light source car antenna 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com