Compressor structure and air conditioner comprising same

A technology for compressors and compression parts, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc. It can solve the problems of limited noise reduction technology and limited space in high-pressure chambers, and achieves reduction of high-frequency noise, attenuation of airflow pulsation, Effect of reducing low-frequency impact noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

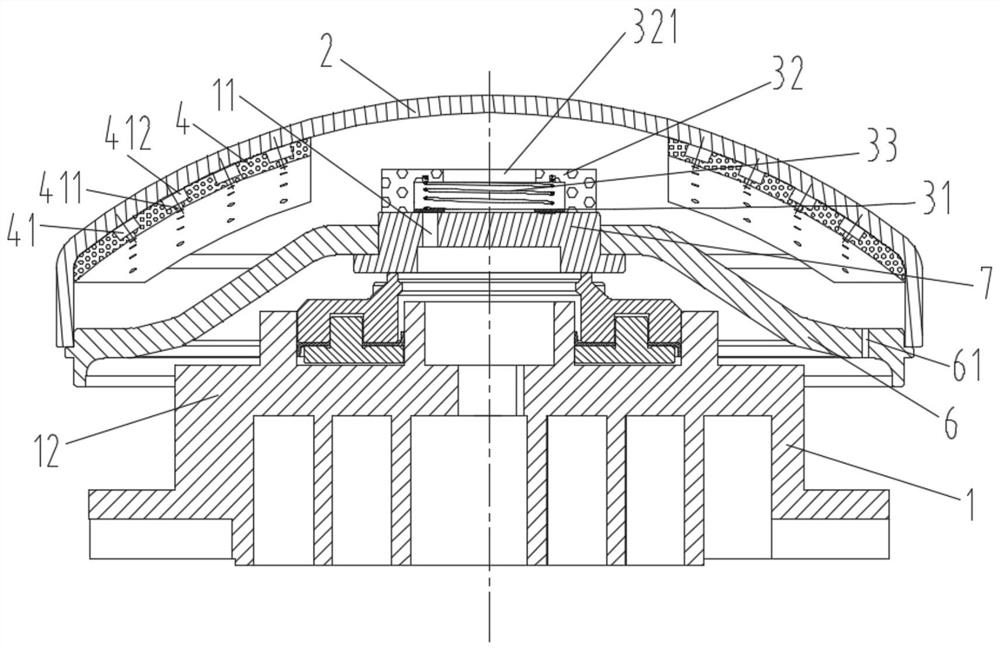

[0045] see in conjunction figure 1 As shown, according to an embodiment of the present application, a compressor structure includes: a compression part 1, and the compression part 1 includes a first exhaust port 11;

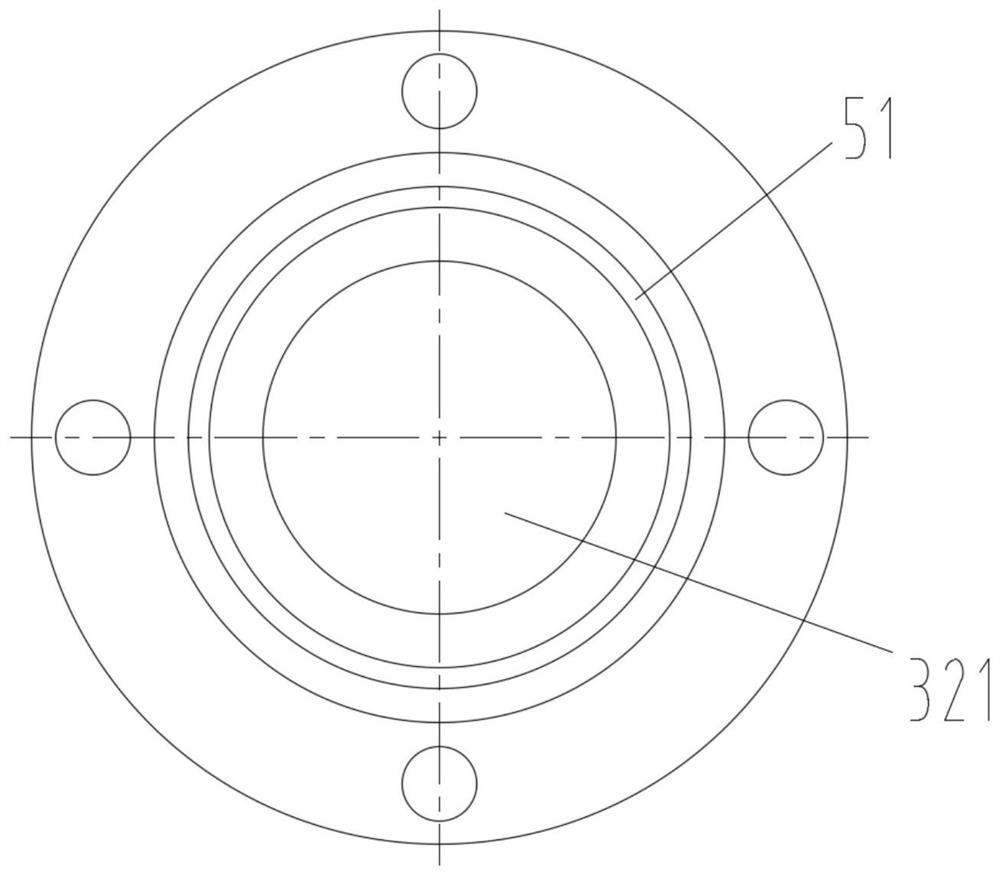

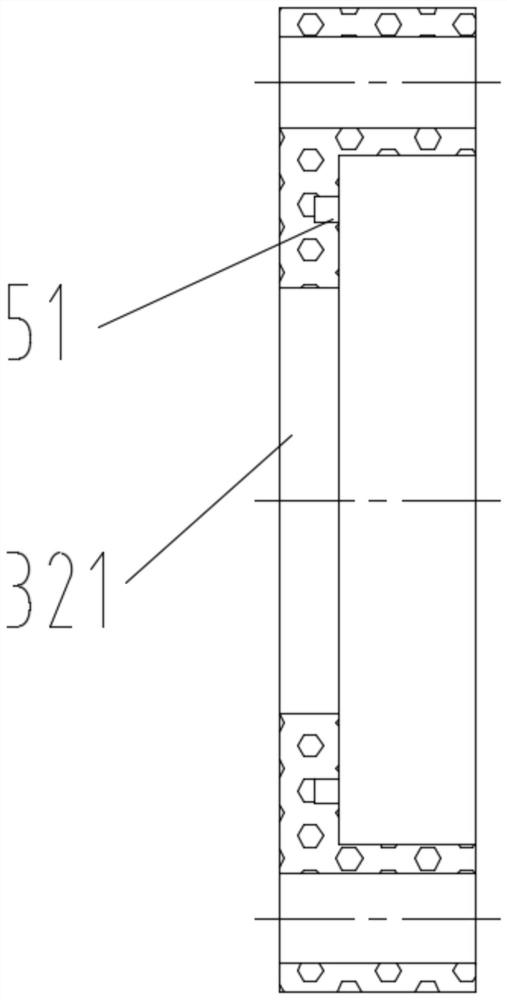

[0046] The compressor structure also includes: a valve plate 31, a valve plate limiter 32 and an elastic member 33; the valve plate 31 is covered on the first exhaust port 11; the valve plate limiter 32 is arranged on the compression part 1, and is connected with The position of the valve plate 31 is corresponding; the elastic member 33 is arranged between the valve plate limiter 32 and the valve plate 31;

[0047] And / or, the compressor structure further includes a shell, the compression part 1 is arranged inside the shell, and the shell includes an end cover 2; the end cover 2 is provided with a second exhaust port 21; the inner surface of the end cover 2 is provided with a drop The noise part 4, the elastic part 33 is arranged between the valve plate limiter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com