A kind of dedusting equipment for mine and its using method

A technology for dust removal equipment and mines, which is applied in mining equipment, mechanical equipment, dust prevention, etc. It can solve the problems of fixed absorption range of the gas collection pipe, inability to adapt to dust removal, and increase, so as to improve the dust removal effect, improve dust absorption performance, and improve The effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

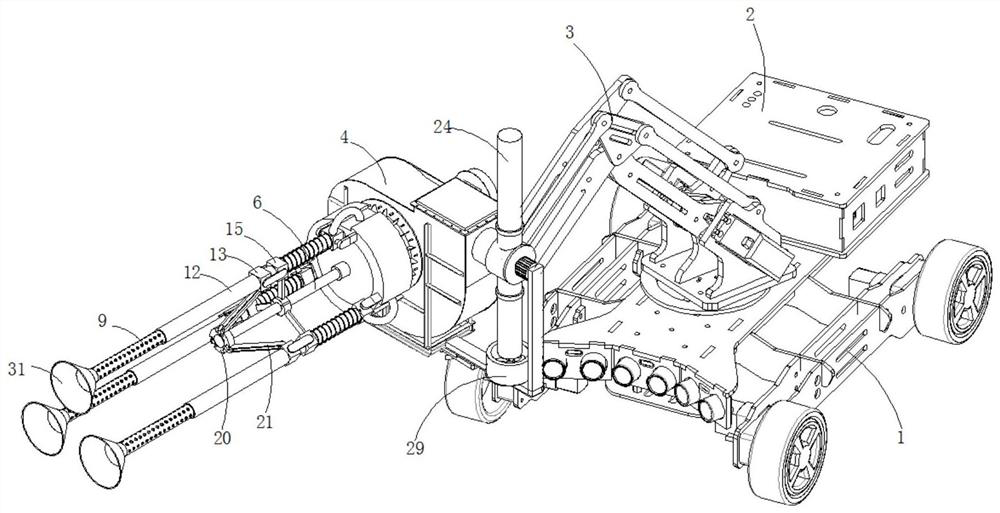

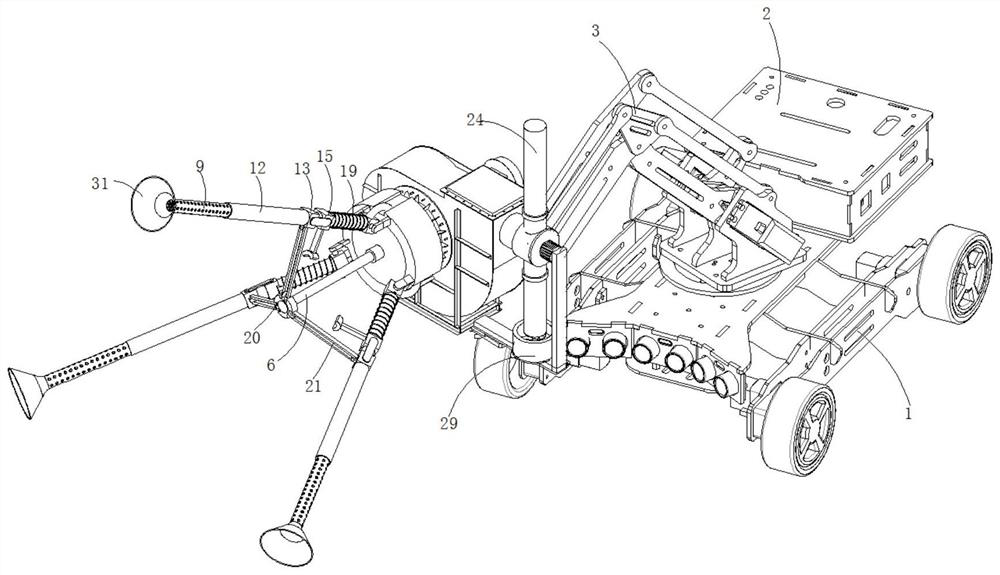

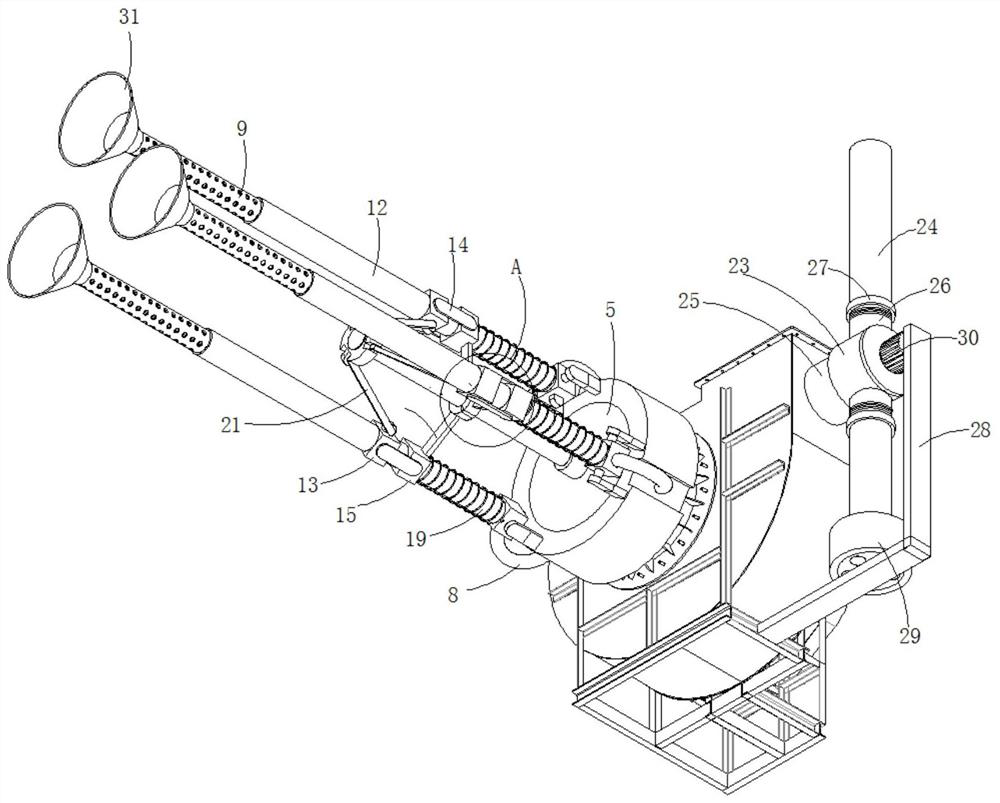

[0038] refer to Figure 1-6 , a kind of dust removal equipment for mines, including car body 1, PLC electric control box 2 and mechanical arm 3, PLC electric control box 2 and mechanical arm 3 are installed on the car body 1, and the moving end of mechanical arm 3 is fixed through a bracket There is a centrifugal fan 4, the air inlet of the centrifugal fan 4 is fixedly connected with a sealing plate 5, the middle part of the sealing plate 5 is equipped with a telescopic cylinder 6, and the edge of the sealing plate 5 is movably connected with an evenly distributed air cylinder 7, and the air cylinder 7 and A snakeskin hose 8 is communicated between the air inlets, and the end of the air duct 7 away from the snakeskin hose 8 is fixedly connected with an air collecting pipe 9, and the air collecting pipe 9 is provided with evenly distributed air collecting holes 10, and the air collecting pipe 9 The inner wall is fixed with a spirally arranged wind deflector 11, and the wind def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com