Continuous oil tube fracturing and downhole throttling producing integrated process tubular pile and method thereof

A process string and tubing technology, applied in the field of coiled tubing fracturing and downhole throttling production integrated process string, can solve the problem that gas wells cannot be downhole throttling, improve liquid carrying capacity, reduce input cost, sit reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

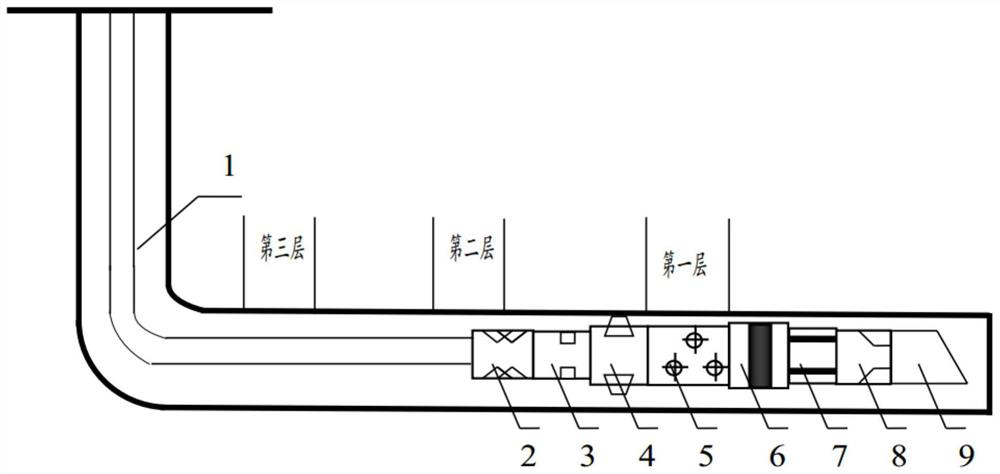

[0031] Such as figure 1 As shown, a coiled tubing fracturing and downhole throttling production integrated process string of the present invention includes a coiled tubing 1, a connector 2, a shearing handle 3, a casing collar positioner 4, a hydraulic injector 5, Packer 6, sliding sleeve seat 7, hydraulic delivery tool 8 and downhole restrictor 9. The coiled tubing 1 is connected to the hydraulic pressure drop 3 through the connector 2, the casing collar positioner 4 is connected to the lower end of the shear line 3, the casing collar positioner 4 is connected to the hydraulic jet 5, and the hydraulic jet 5 There is an inner sliding sleeve to block the tunnel, and it can only work normally after the ball is started. The lower end of the hydraulic jet 5 is connected to the packer 6, the lower end of the packer is connected to the sliding sleeve seat 7, and the lower end of the sliding sleeve seat 7 is connected to the hydraulic delivery tool. 8. The lower end of the hydraulic...

Embodiment 2

[0041] refer to figure 1 Embodiments of the present invention are further described:

[0042]An integrated process string of coiled tubing fracturing and downhole throttling production, the process string includes coiled tubing 1, connector 2, shearing handle 3, casing collar positioner 4, hydraulic injector 5, seal Spacer 6, sliding sleeve seat 7, hydraulic delivery tool 8 and downhole restrictor 9. The coiled tubing 1 is connected to the hydraulic pressure drop 3 through the connector 2, the casing collar positioner 4 is connected to the lower end of the shear line 3, the casing collar positioner 4 is connected to the hydraulic jet 5, and the hydraulic jet 5 There is an inner sliding sleeve to block the tunnel, and it can only work normally after the ball is started. The lower end of the hydraulic jet 5 is connected to the K344 packer 6, the lower end of the K344 packer is connected to the sliding sleeve seat 7, and the lower end of the sliding sleeve seat 7 is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com