Method for treating high-rise building foundation in non-self-weight collapsible loess area

A technology for collapsible loess and high-rise buildings, which is applied in construction, foundation structure engineering, sheet pile walls, etc. It can solve the problems of high cost and limited improvement of foundation strength, achieve obvious economic benefits, save construction costs, and reduce loess wetness. trapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

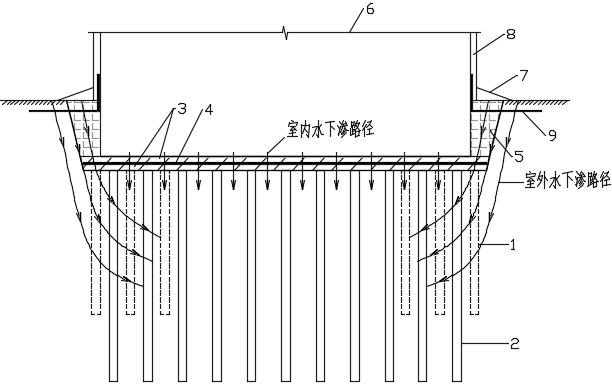

[0024] Such as Figure 1-2 As shown, a non-self-weight collapsible loess region high-rise building foundation treatment method is characterized in that it includes the following steps:

[0025] Step 1: The foundation pit is excavated to the design elevation, and the compaction pile 1 is set up for construction; the compaction pile 1 is set on the outer edge of the foundation not less than 1 / 2 of the thickness of the collapsible soil layer or not less than 5m; the compaction pile 1 The pile diameter is 300-400mm, the pile length exceeds the lower limit of the collapsible soil layer by not less than 0.5m, and the distance between one compacted pile is 2-2.5 times the pile diameter; when the initial pressure of the collapsibility is less than 200kPa, the distance between one compacted pile is 2 times the pile diameter; when the initial pressure of the collapsibility is greater than 200kPa, the distance between 1 compaction pile is 2.1-2.5 times the pile diameter; The thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com