A heat treatment method for magnesium alloys used in large-scale satellites

A heat treatment method and large-scale technology, which are applied in the field of heat treatment of magnesium alloys for large-scale satellites, can solve problems such as casting deformation, and achieve the effects of reducing casting stress, preventing new deformation, and avoiding casting cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

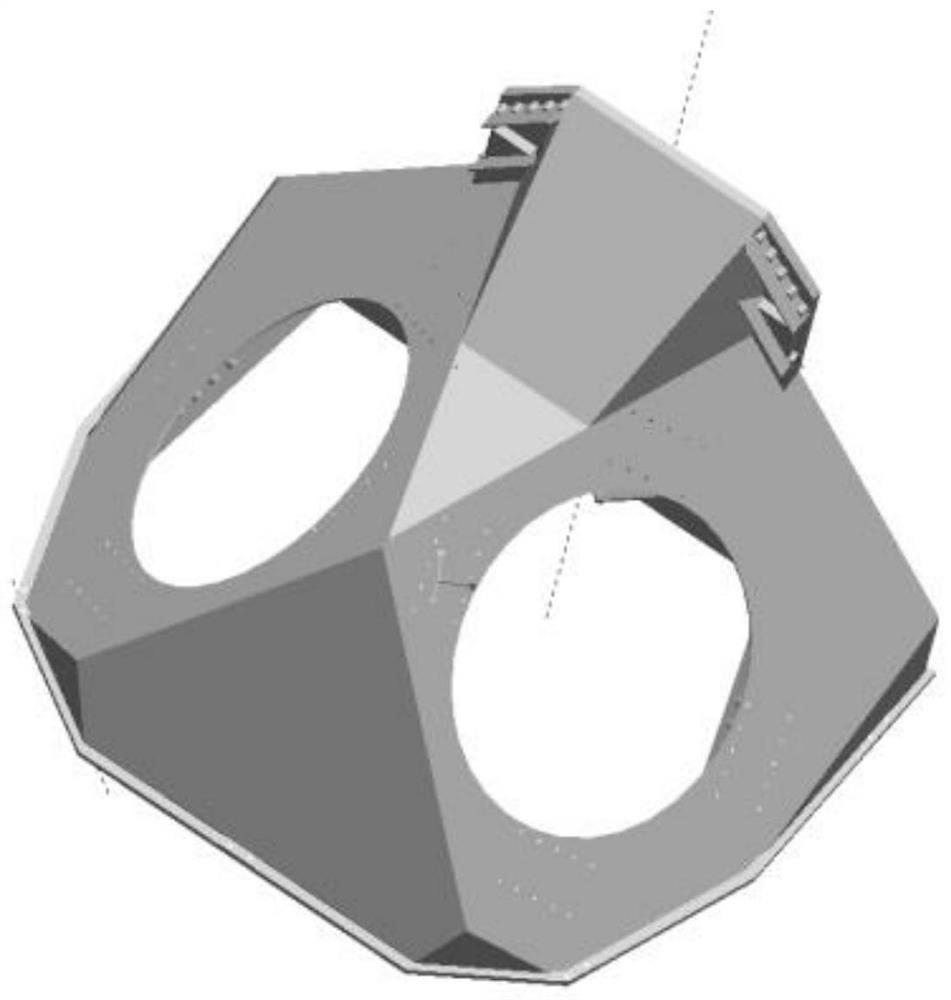

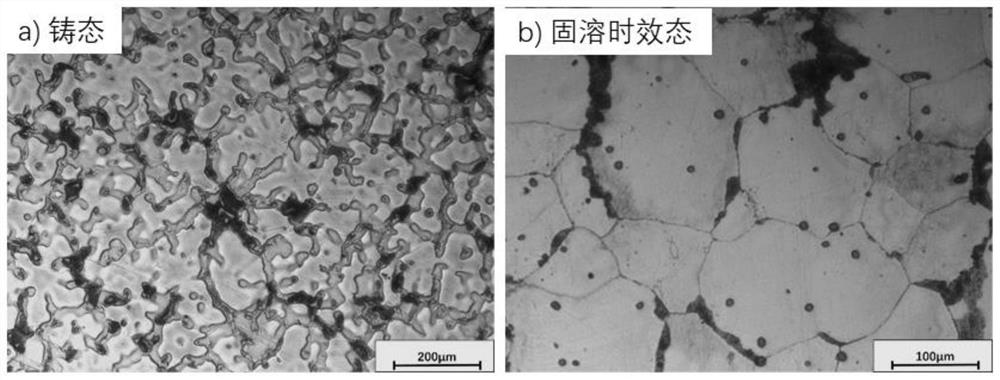

[0046] Cast the momentum wheel bracket with the size of 1389mm×1000mm×900m (the structure diagram is as follows figure 1 , the magnesium alloy includes the following components by mass percentage: Al 8%, Zn 0.4%, Mn 0.2%, Fe 0.02%, Si 0.1%, Ni0.001%, Cu 0.08%, and the balance of Mg) and high rigid thermal conductivity tooling Solution treatment after assembly: first raise the temperature (heating rate: 15°C / min) to 365°C, and keep it at 365°C for 3 hours; then raise the temperature (heating rate: 15°C / min) to 420°C, and keep it at 420°C for 17 hours; Cool the castings and tooling with the furnace to 175°C and then take them out of the furnace and quickly remove them. After unloading, the temperature drops to 35°C; after the solution-treated momentum wheel bracket and the high-rigidity heat-conducting tooling are assembled with high external force, aging treatment: first heat up (The heating rate is 15°C / min) to 180°C, keep the temperature at 180°C for 17 hours, remove the cast...

Embodiment 2

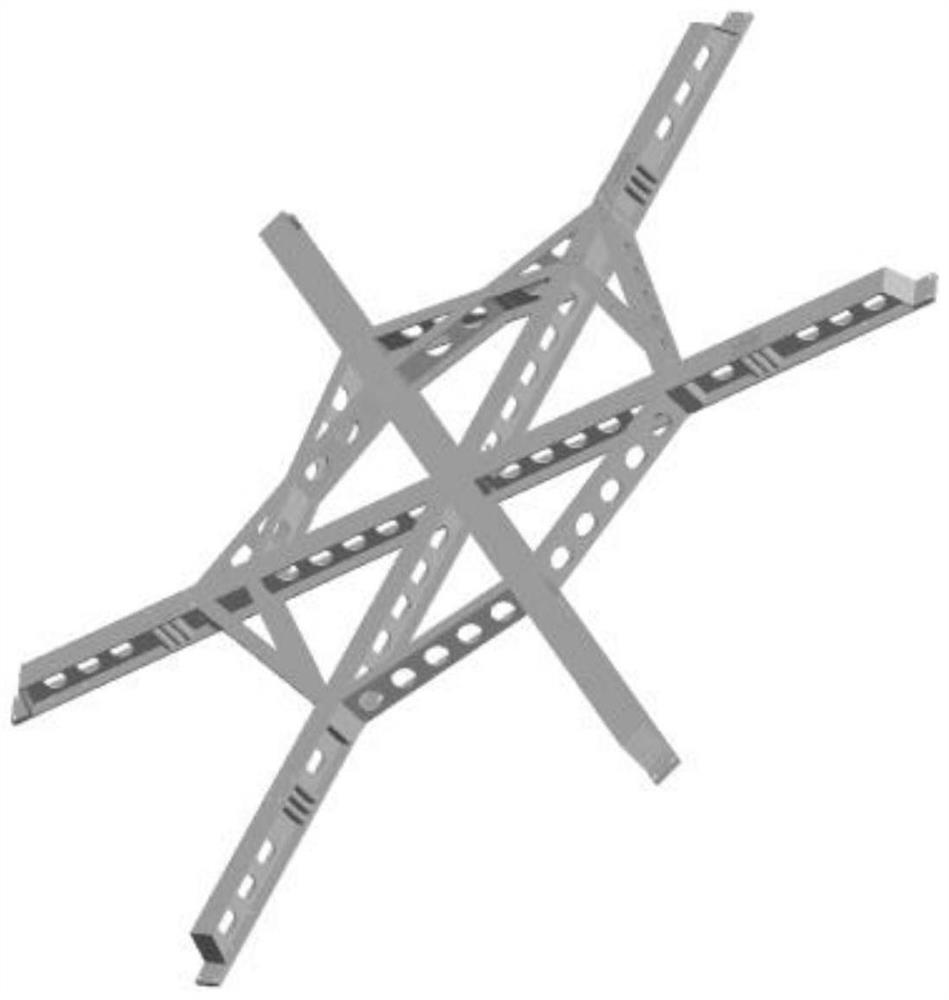

[0049] Change the size to Momentum wheel bottom plate casting (structural schematic diagram as figure 2 , the magnesium alloy includes the following components by mass percentage: Al 8.5%, Zn 0.6%, Mn 0.4%, Fe 0.01%, Si0.15%, Ni0.007%, Cu 0.04%, the balance of Mg) and high rigidity thermal conductivity tooling Solution treatment after assembly: first raise the temperature (heating rate: 20°C / min) to 370°C, and keep it at 370°C for 2 hours; then raise the temperature (heating rate: 20°C / min) to 420°C, and keep it for 12 hours; Castings and tooling are cooled to 190°C with the furnace and then come out of the furnace quickly, and the temperature drops to 25°C after demounting; after the solution-treated momentum wheel bottom plate and the high-rigidity and easy-to-heat-conducting tooling are assembled with high external force, aging treatment is carried out: firstly, the temperature is raised (The heating rate is 20°C / min) to 190°C, keep the temperature at 190°C for 8 hours, ...

Embodiment 3

[0051] A momentum wheel bracket casting (8.5% Al, 0.6% Zn, 0.4% Mn, 0.01% Fe, 0.15% Si, 0.007% Ni, Cu 0.04%, and the balance of Mg) with a size of 1389mm×1000mm×900m and high After the rigid heat-conducting tooling is assembled, solution treatment is carried out: firstly, the temperature is raised (the heating rate is 20°C / min) to 360°C, and the temperature is kept at 360°C for 3 hours; then the temperature is raised (the heating rate is 20°C / min) to 415°C, and the Insulate for 18 hours; finally cool the castings and tooling to 170°C with the furnace and take them out of the furnace quickly. Treatment: first raise the temperature (heating rate is 20°C / min) to 195°C, keep it at 195°C for 16 hours, remove the casting and tooling quickly after they are taken out of the furnace, and the temperature drops to 10°C after removal. Take the standard sample and measure the tensile strength at room temperature as 295MPa, the yield strength as 167MPa, and the elongation as 7.5%.

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com