Method for extracting, separating and refining salicin from willow

A technology of salicin and willow tree, applied in the field of extraction, separation and purification of salicin, can solve the problems of increasing technical control points, unmentioned product yield, cumbersome production process, etc., to reduce pollution, slow down membrane pollution, and reduce cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

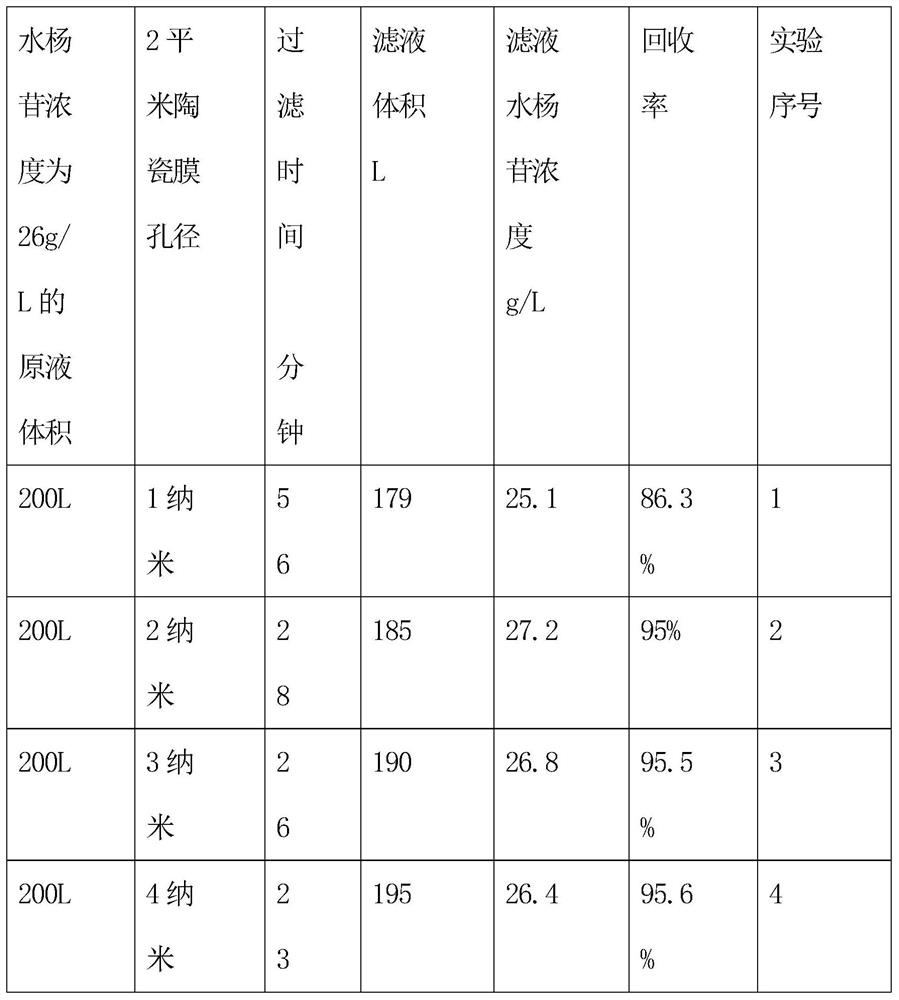

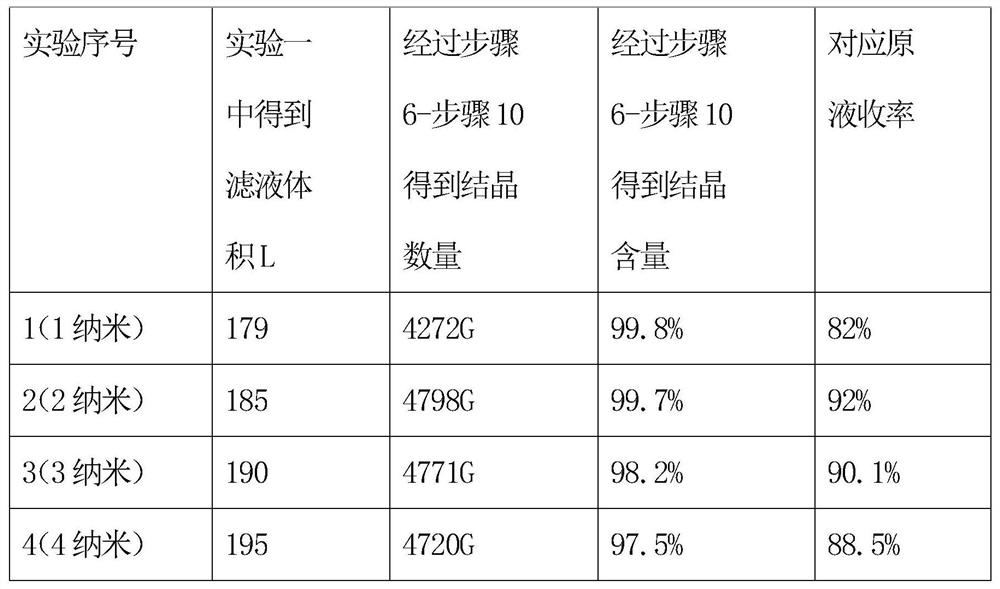

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0024] This specific embodiment adopts following technical scheme: its operating steps are as follows:

[0025] 1. Use white willow bark or fresh willow branches as raw materials, crush them into 20 mesh small granules for later use;

[0026] 2. Put in 8% quicklime by weight of the raw material, stir well and evenly, use a rapid instrument to detect the moisture content of the raw material, and spray an appropriate amount of water to ensure that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com