Sewage treatment and purification equipment

A purification equipment and sewage treatment technology, which is applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of sewage leakage in the treatment of filter devices, and achieve good support effect and good buffer The effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

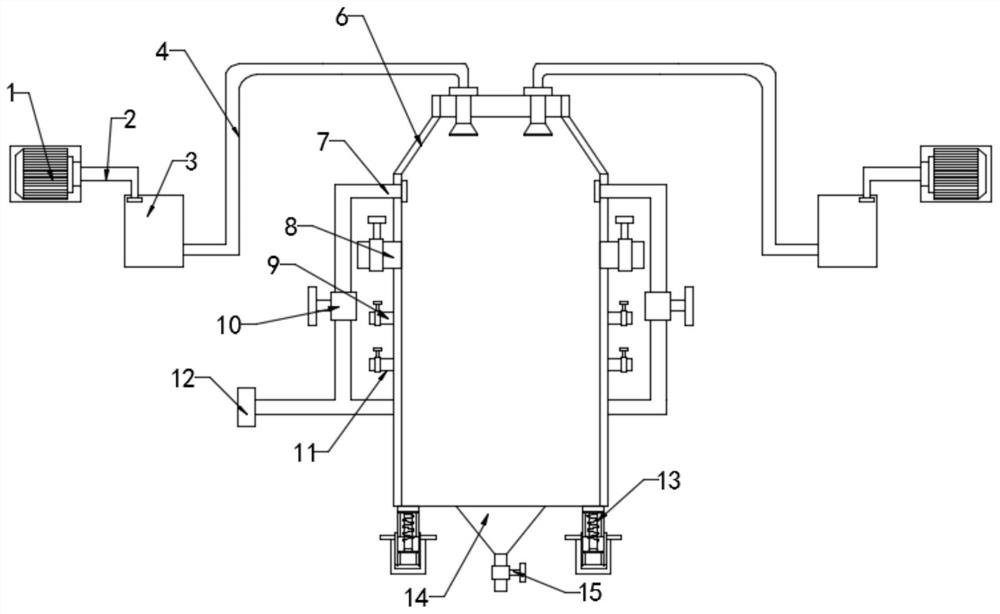

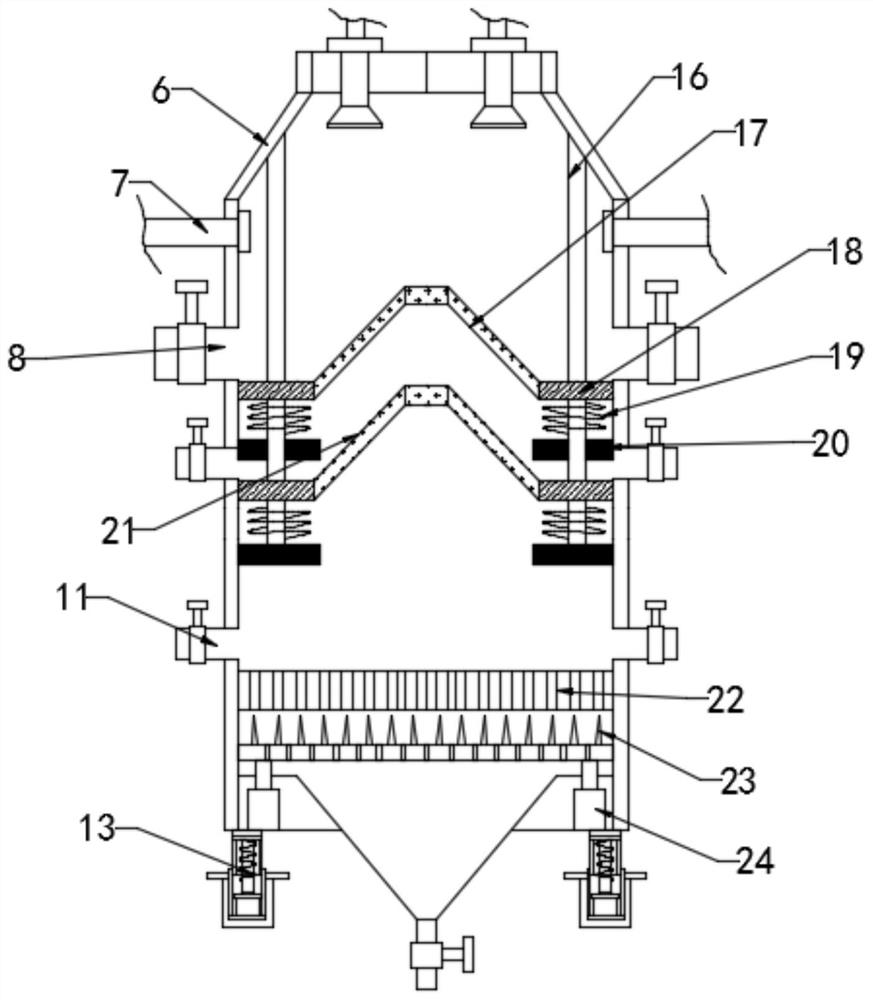

[0019] see figure 1 , in Embodiment 1 of the present invention, a sewage treatment and purification equipment, which includes: a purification equipment body 6, the left and right sides of the top of the purification equipment body 6 are provided with liquid inlet components, and the left and right sides of the upper end of the purification equipment body 6 are connected to the inlet There are two water pipes 7 and two water inlet pipes 7, and water inlet valves 10 are installed on the two water inlet pipes 7, and one end of the two water inlet pipes 7 is connected to the water inlet port 12; the lower end of the purification equipment body 6 is provided with an outlet Sewage pipe, purification equipment body 6 inside is provided with filtering assembly; said purification equipment body 6 is provided with a liquid outlet pipe 14 in the middle of the lower end, and a liquid outlet valve 15 is installed on the liquid outlet pipe 14; the left and right sides of the purification equ...

Embodiment 2

[0022] Further, the number of the liquid inlet assembly is two, and the liquid inlet assembly includes an air pump 1, a liquid mixing tank 3 and an atomizing nozzle 5, the air pump 1 is connected to the liquid mixing tank 3 through the gas delivery pipe 2, and the liquid mixing tank 3 is connected to the liquid mixing tank 3 through the liquid delivery pipe 4 Connected with the atomizing nozzle 5, the atomizing nozzle 5 is arranged inside the purification equipment body 6;

[0023] Put the sewage disinfectant into the mixed liquid tank 3 and start the air pump 1 after mixing evenly. The air pump 1 delivers high-pressure gas to the inside of the mixed liquid tank 3 through the air delivery pipe 2. After the high-pressure gas enters the mixed liquid tank 3, the sewage disinfectant is transported to the The position of the atomizing nozzle 5 inside the purification equipment body 6 is atomized and sprayed, so that the atomized disinfectant is fully stirred and mixed with the sewag...

Embodiment 3

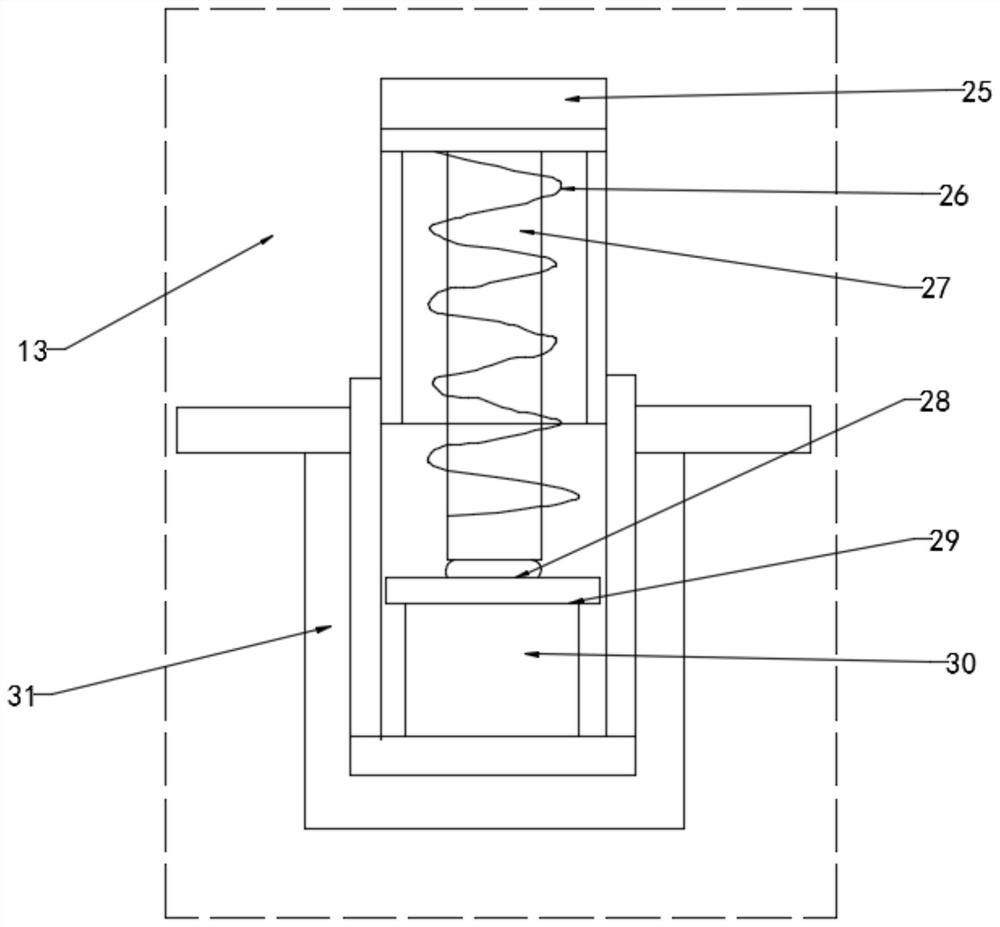

[0031] see image 3 , further, the support assembly 13 includes a buffer cylinder 25 and a buffer base 31, the upper end of the buffer cylinder 25 is connected and fixed to the purification equipment body 6, and the lower end of the buffer cylinder 25 is movably installed inside the buffer base 31;

[0032] Specifically, the buffer cylinder 25 and the second sieve plate 21 are sequentially connected by a spring buffer block 27, a suction cup 28, a protection plate 29 and a spring steel block 30, and a second compression spring 26 is movably installed on the outside of the spring buffer block 27;

[0033] Through the cooperation of the second compression spring 26, the spring buffer block 27, the suction cup 28 and the protective plate 29, the buffer cylinder 25 of severe vibration can realize multiple buffering and shock absorption, and the shock absorption of the purification equipment body 6 installed and fixed at the upper end of the buffer cylinder 25 can be improved. Effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com