High-precision separation equipment for ores

A high-precision, high-quality equipment technology, applied in the direction of stone processing equipment, solid separation, stone processing tools, etc., can solve the problems that affect the economic benefits of enterprises, limit production breakthroughs, and many operating steps, and achieve high-precision sorting effects. Realize Sorting effect, effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

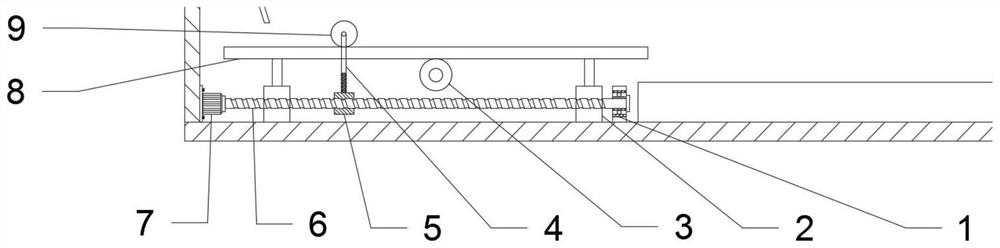

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated by the following examples.

[0028] A kind of ore high-precision sorting equipment, including an integrated sorting box, the integrated sorting box includes a casing 17, the top of the casing 17 is provided with a feeding port 22, and the materials entering from the feeding port 22 fall into the first On the two support plates 19, a lift-type cutter is arranged below the second support plate 19 to lift the material from the slot hole 38 on the second support plate 19 to cut the material for the first time. The push plate 21 moves through the third screen 23, and the finer materials fall from the third screen 23 into the first discharge channel 41, and the thicker materials fall through the third screen 23 from the first inclined plate 24 to the second The unloading channel 44 is limited by the baffle plate 28 that is movable, and a secondary cutting device is arranged above the second unloading channel 44, and the material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com