Manufacturing process for prefabricated wall panels of fabricated building

A prefabricated wallboard and manufacturing process technology, applied in the direction of manufacturing tools, supply devices, unloading devices, etc., can solve problems such as safety hazards, large pores on the surface of prefabricated wallboards, and affecting the structural strength of prefabricated wallboards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

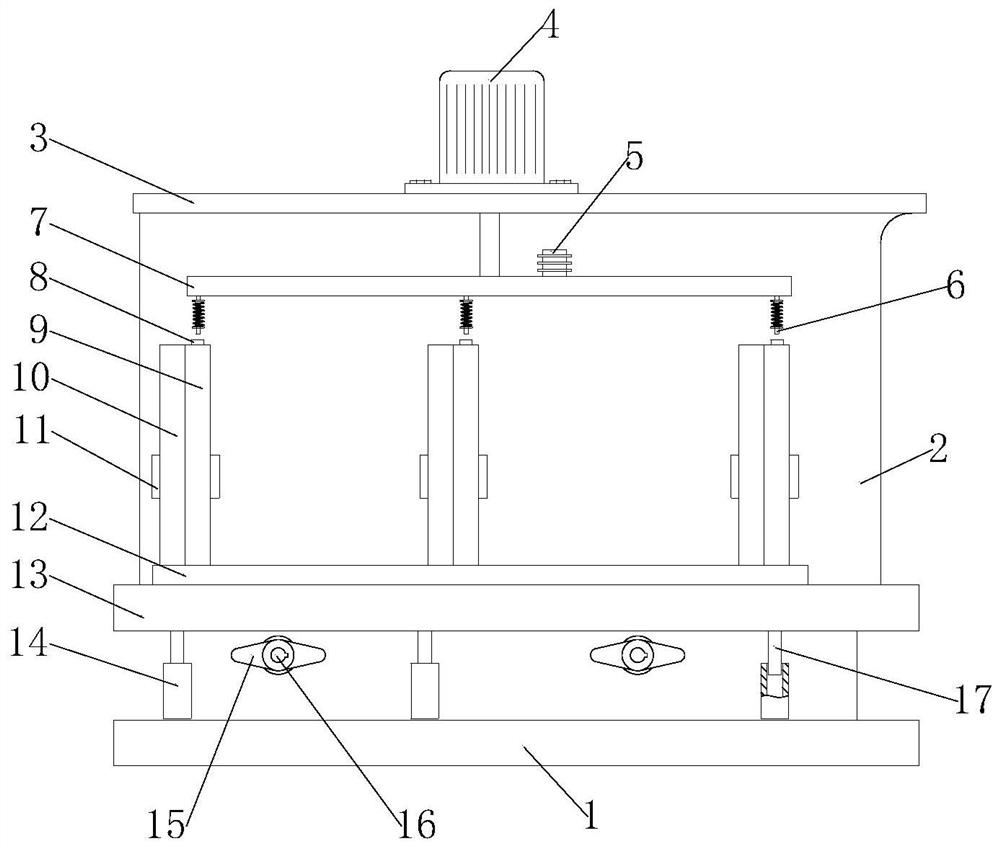

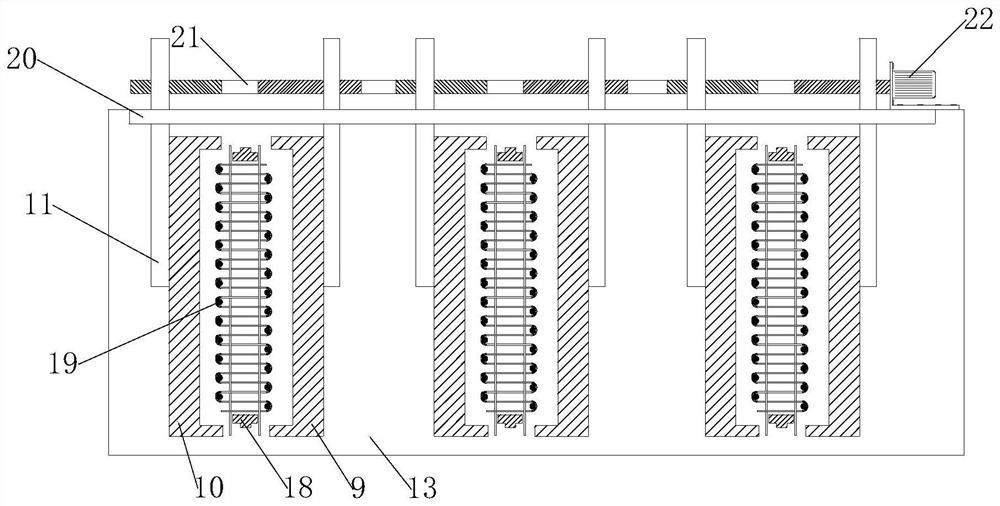

[0043] see Figure 1-11 , which is a schematic diagram of the overall structure of a prefabricated building prefabricated wall panel manufacturing process,

[0044] A manufacturing process of prefabricated wall panels for prefabricated buildings, which is used in building construction. The prefabricated wall panels are obtained by pouring concrete into the steel frame to obtain prefabricated wall panels. After the device has been matched, the prefabricated building wall panel manufacturing device includes a bottom support plate 1. The top of the bottom support plate 1 is provided with a support rib 2 that is upright ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com