Robot connecting mechanism convenient to disassemble and assemble

A connecting mechanism and robot technology, applied in the field of robotics, can solve the problems of the hydraulic cylinder not being used normally, the hydraulic cylinder disassembly process is complicated, etc., and achieve the effect of improving the degree of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

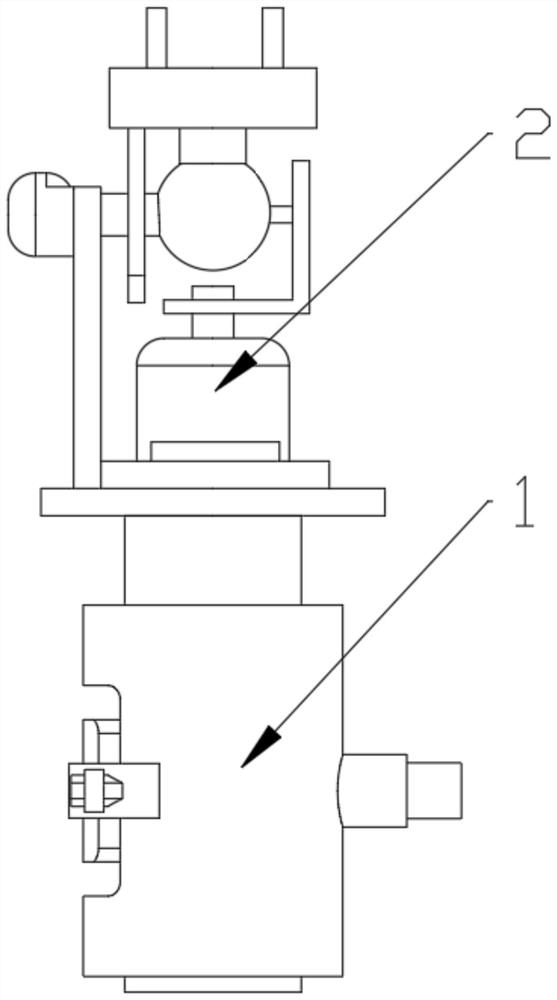

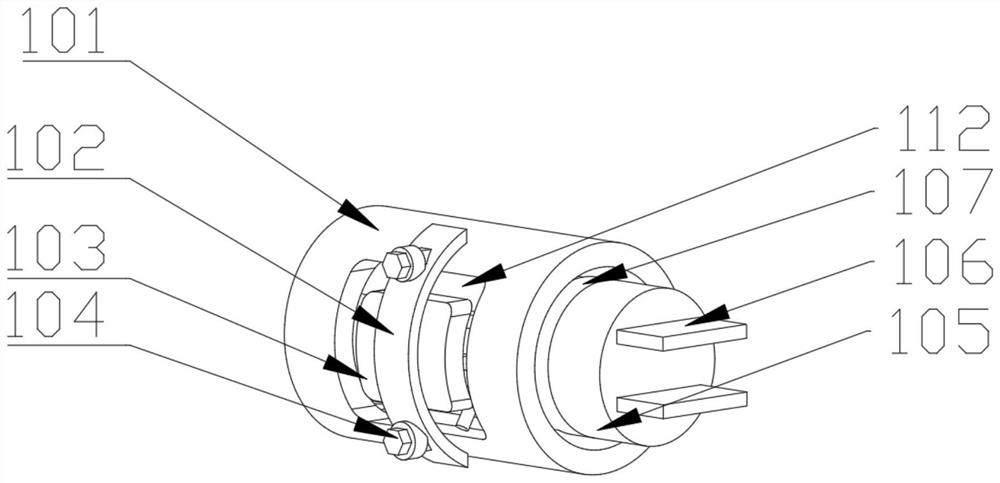

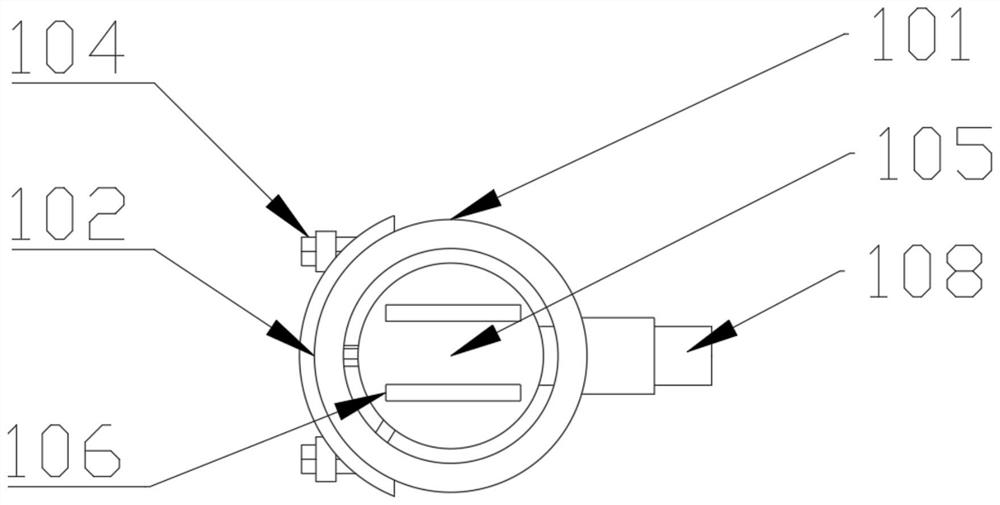

[0026] see Figure 1-6 , a robot connection mechanism that is easy to disassemble, including a telescopic functional part 1 and a rotating functional part 2, the telescopic functional part 1 is connected to the lower end of the rotating functional part 2, and the telescopic functional part 1 includes an outer ring housing 101, a sliding rod 111 and an inner ring housing 107, the outer ring housing 101 is provided with an inner ring housing 107, and the inner ring housing 107 is driven by the sliding rod 111; the outer ring housing 101 A limit ring 112 for the sliding rod 111 to slide is provided on the circumferential surface of the outer ring housing 101, and a first rotating shaft 108 is also pierced on the side of the outer ring housing 101; A connecting block 109 is arranged inside, and one end of the connecting block 109 is fixedly connected to the first rotating shaft 108, and the first rotating shaft 108 is set in the square hole, and the other end is fixedly connected ...

Embodiment 2

[0033] In order to further improve the activity capacity of the present invention, special increase improvement on the basis of embodiment 1, improvement is: please refer to Figure 1-6 , the rotating function part 2 includes a moving ball 207, a first motor 203 and a second motor 210; the first motor 203 and the second motor 210 are respectively located on two sides adjacent to the moving ball 207, and the The bottom of the first motor 203 is fixedly connected with a connecting clamp 201, and the first motor 203 is connected with an L-shaped plate 205 through a second rotating shaft 204, and a moving head 206 is installed on the L-shaped plate 205, and the moving head 206 Engaged in the groove provided on the moving ball 207; the second motor 210 is connected to the side plate 209 through the third rotating shaft 202, and the side of the side plate 209 rotates with the moving ball 207 connection; the second motor 210 is affixed to the connecting clamp 201 through a fixed fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com