A method for low-temperature continuous batching in the chlorination step of sucralose production

A sucralose, continuous technology, which is applied in the field of continuous batching at low temperature steps in a chlorination section, can solve the problems of frequent fluctuations in process indicators, low production efficiency, low reaction temperature, etc., and achieves stable production process index control, productivity level improvement, and improvement Effects of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

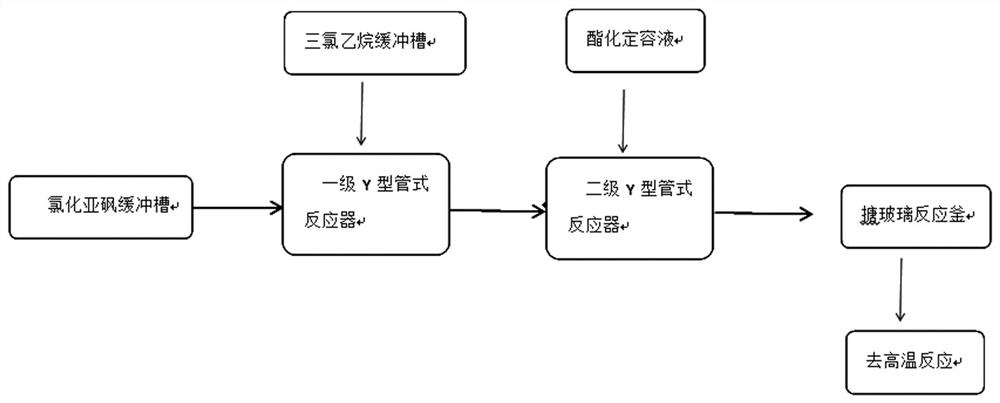

[0018] Mix trichloroethane cooled to -1~5 degrees Celsius at a flow rate of 1800L / H, and thionyl chloride at a flow rate of 400L / h, adjust the flow rate with a pump, and pump it into the two sides of the first-stage Y-shaped tubular reactor at the same time. The mixed liquid at the outlet end of the first-stage Y-shaped tubular reactor is quenched with -20°C frozen brine to 0-5°C and then poured into the buffer tank.

[0019] Pump the mixed liquid in the buffer tank at the flow rate of 1300L / H, and the esterification constant volume solution (300g / L) at the flow rate of 400L / H to the two inlet ports of the secondary Y-type tubular separator. The secondary mixed liquid flowing out of the outlet of the tubular separator is quenched again with -20°C frozen brine to 0~5°C, and then poured into a glass-lined reactor with stirring, and continues to cool down with frozen brine, and maintains it at -5 to 5°C. Keep it cold for one hour at 15°C. The secondary mixed liquid with uniform i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com