Electric drive type seed sowing device, device and method

A kind of seed metering device and technology of seed metering device, which is applied in the field of agricultural machinery, can solve the problems of high driving torque requirement of seed metering device, great difficulty in implementing electric drive seed metering, and affecting the reliability of machines and tools, so as to save manpower and improve rowing efficiency. Seed effect, the effect of improving the uniformity of seeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

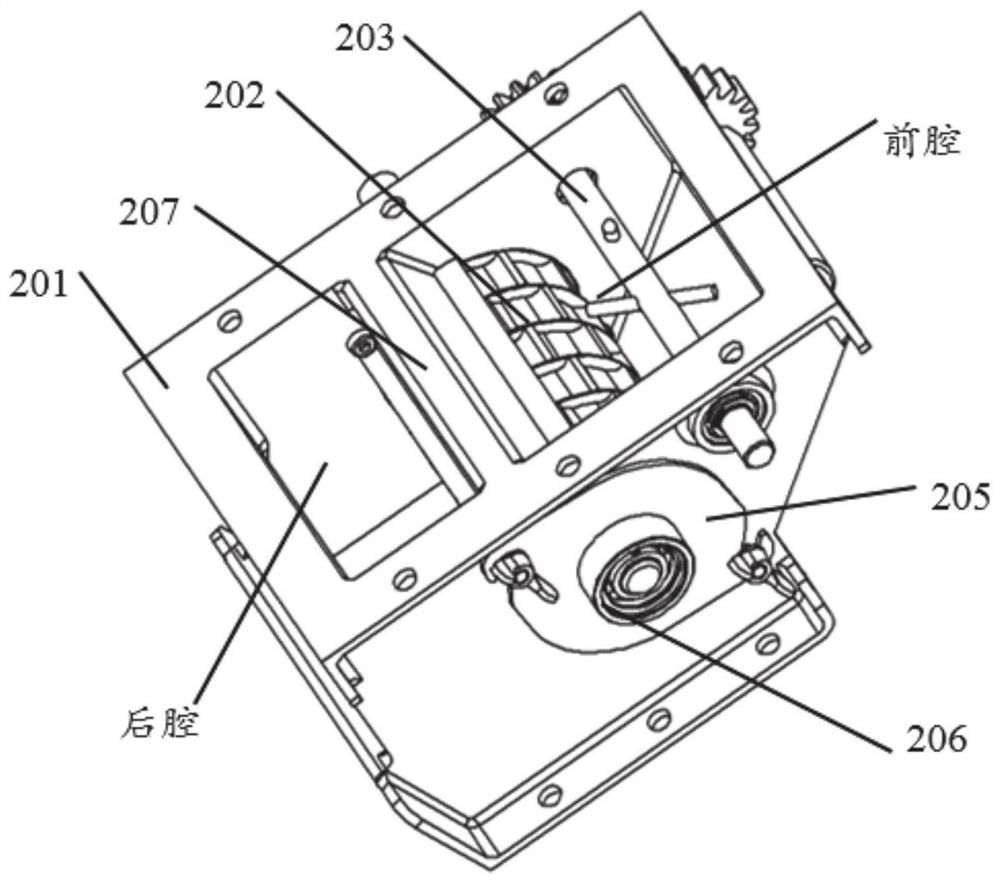

[0042] This embodiment provides an electric drive type metering device, such as figure 2 with image 3As shown, it includes housing 201, spiral seeding wheel group 202, stirring shaft group 203 and driving device. It is connected with the spiral seeding wheel group 202 and the stirring shaft group 203.

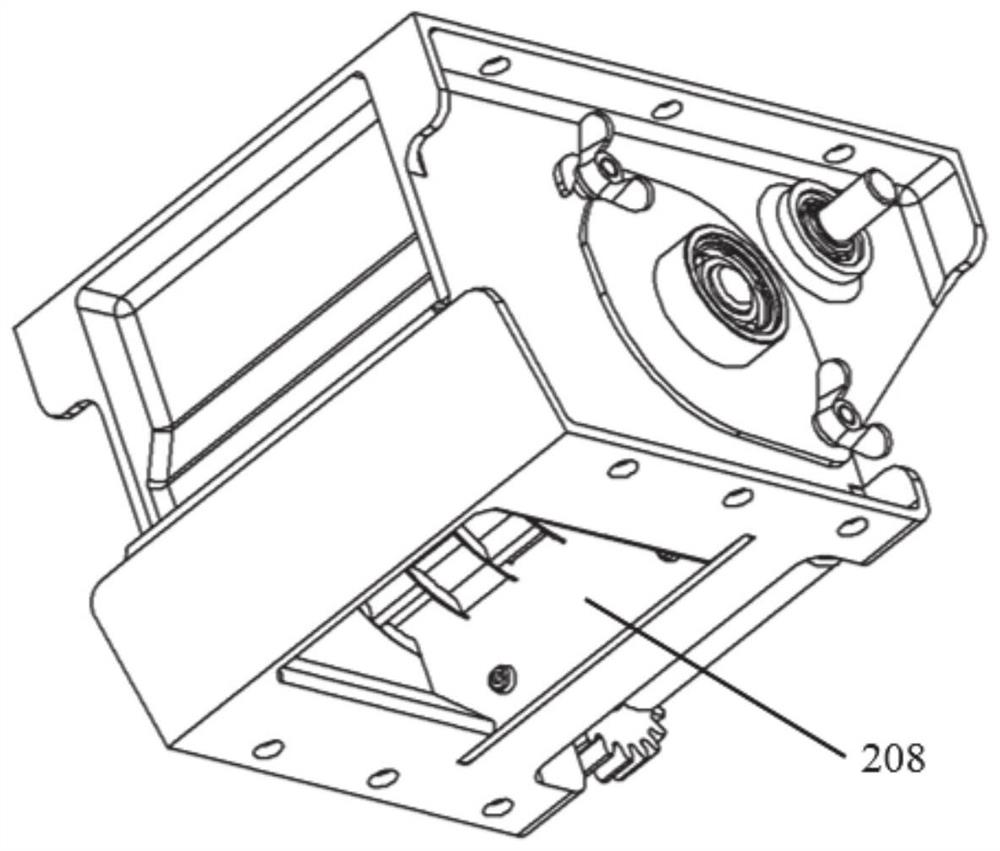

[0043] Specifically, the inside of the housing 201 is a cavity, and its top and bottom are respectively open structures. The spiral seed wheel set 202 is horizontally installed inside the housing 201, and the spiral seed wheel set 202 is provided with a seed wheel cover 207, which is welded and fixed to both sides of the shell 201, and the seed wheel The protective cover 207 is set concentrically with the spiral seed row set 202 . A seed clearing plate 208 is provided below the spiral seed row group 202, and the seed wheel cover 207 and the seed clearing plate 208 divide the housing 201 into a front cavity and a rear cavity. Wherein, the front cavity is located on one sid...

Embodiment 2

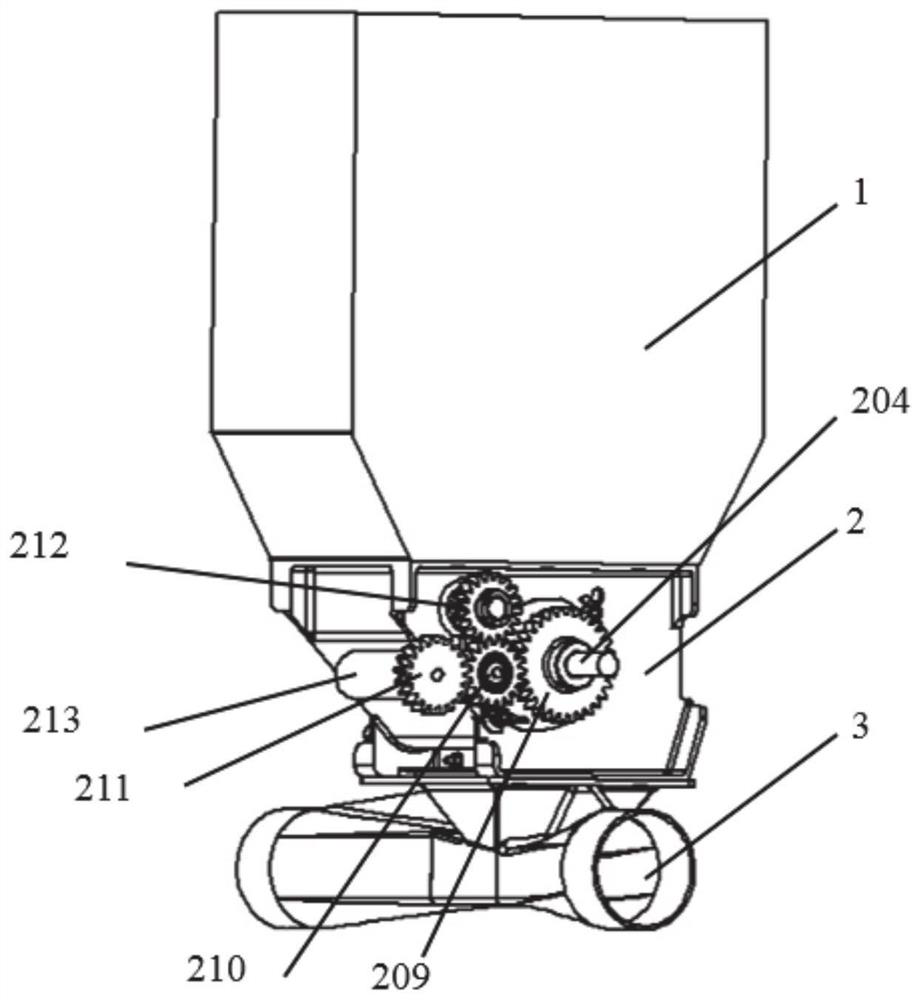

[0054] This embodiment provides an electrically driven seed metering device, which includes the seed meter 2 described in Embodiment 1, and also includes a seed box 1 and a Venturi air duct 3, such as figure 1 As shown, the seed box 1 is installed above the seed meter 2, and the Venturi air duct 3 is installed below the seed meter 2. The Venturi air duct 3 can realize negative pressure seed suction, and the seeds falling in the seed meter 2 are mixed with the high-speed airflow generated by the fan through the Venturi duct 3 to form a uniform and orderly seed flow and enter the next stage of distribution.

[0055] Such as Image 6 As shown, the Venturi air duct 3 includes an air duct 301 and a valve 302, and the top of the air duct 301 is provided with a material inlet, the top of the material inlet is connected to the bottom of the housing 201 of the seed meter 2, and the bottom of the material inlet is connected to the bottom of the air duct 301. Tube 301 is connected. And...

Embodiment 3

[0057] The present embodiment provides a kind of seeding method adopting electric driving type seeding device, comprises the following steps:

[0058] 1) Seed filling: The external positive pressure airflow passes through the straight pipe of the Venturi tube 3 to keep the feed inlet in a negative pressure state. Put the seeds into the seed box 1, and the seeds fall from the seed box 1 into the seed metering device 2; when the seeds are filled with the seed storage area in the front cavity, the servo motor 213 rotates through the multi-stage reducer to reduce the speed and increase the torque, and drives the spiral seed metering wheel through gear meshing The group 202 rotates stably over the population resistance.

[0059] 2) Seed cleaning: the spiral seeding wheel set 202 rotates to the bottom after being filled with seeds, and the seed cleaning plate 208 is closely attached to the outer edge of the spiral seeding wheel set 202 to prevent the discharge of the driven layer se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com