Beam string structure with high progressive collapse resistance performance and implementation method of beam string structure

A chord beam and performance technology, applied in the field of long-span prestressed space structures, can solve the problems of insufficient bending resistance of the upper chord beam, prone to collapse, low bending resistance efficiency, etc., to improve the continuous collapse resistance performance, increase redundancy, control Effect of Prestress Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is described in detail:

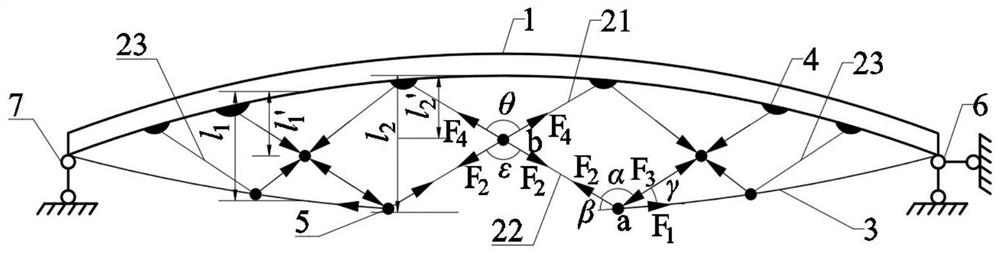

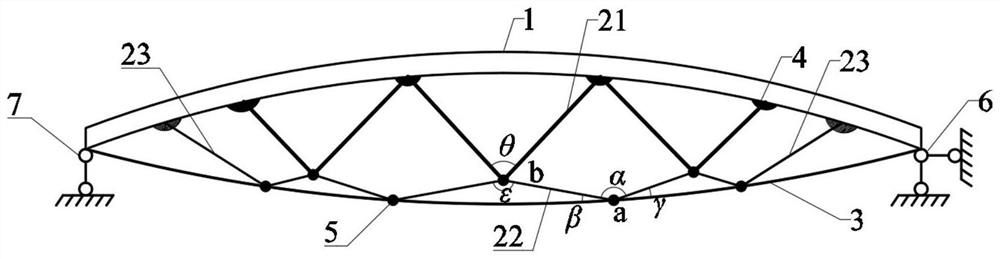

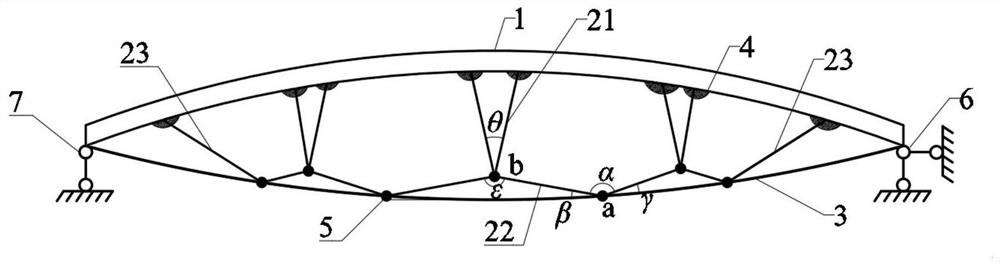

[0039] Such as Figure 1-Figure 4 As shown, the tension beam structure with anti-collapse function of the present invention includes an upper string 1 and a lower cable 3, and the upper string is a beam structure such as a steel beam or a truss beam. A plurality of first nodes are arranged on the upper string beam, a plurality of second nodes are arranged on the lower cable, and a plurality of third nodes are arranged in the space between the upper string beam and the lower cable, and on each third node Four oblique struts are provided, and the four oblique struts are respectively connected to two adjacent first nodes on the upper chord beam and two adjacent second nodes on the down cables, and the outermost first A side diagonal brace is arranged between the node and the second outermost node.

[0040] The four diagonal struts connected to the third node include two upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com