A snow layered turning and throwing device for reshaping and cleaning ski slopes

A flipping device and technology for ski resorts, applied in snow surface cleaning, cleaning methods, construction, etc., can solve the problems of high cost of ski slope remodeling and failure to meet the purity requirements of ski slopes, so as to realize automatic dredging and prevent blockage , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

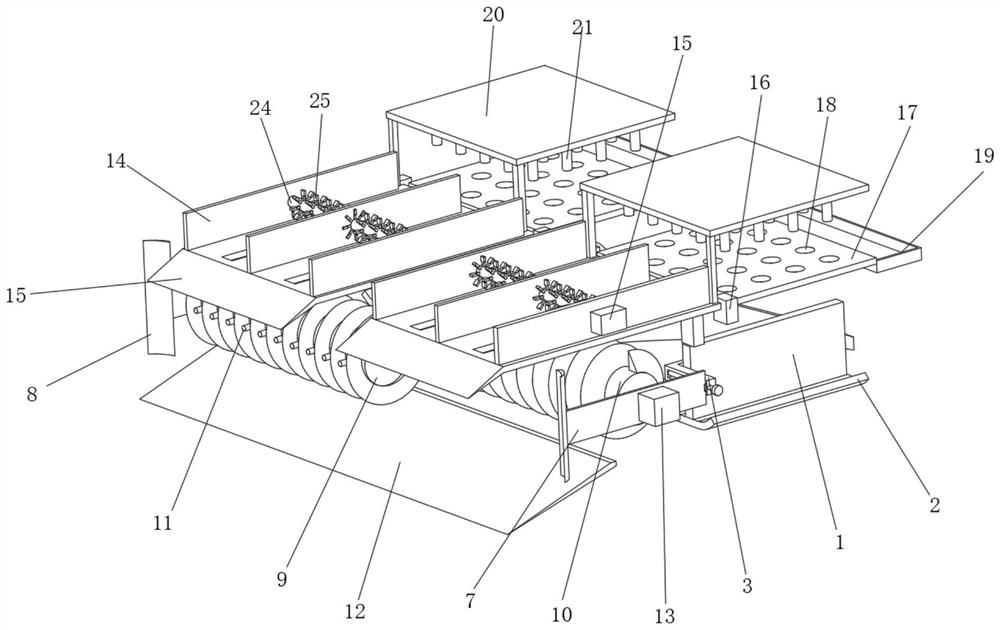

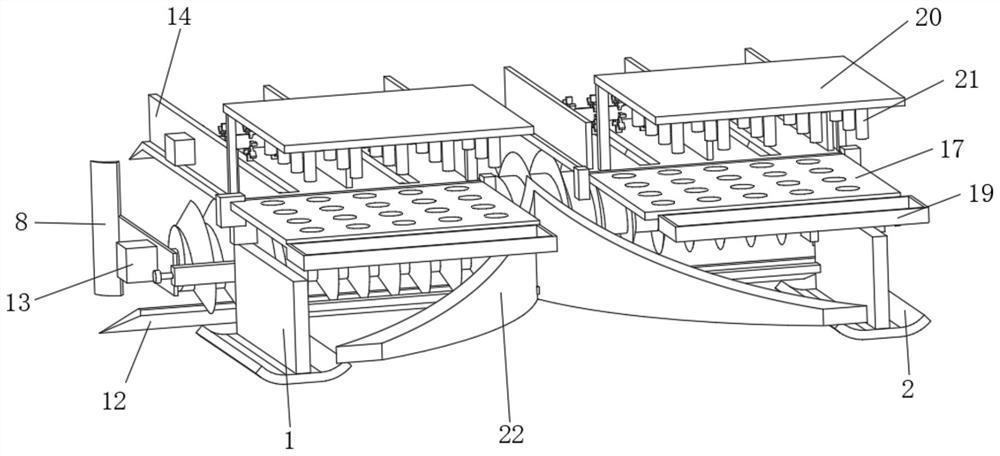

[0036] Such as Figure 1-4 As shown, the present invention provides a technical solution: a snow layer turning and throwing device for ski slope remodeling and cleaning, including a support baffle 1, the bottom of the support baffle 1 is fixedly connected with a walking slide 2, and the support baffle The front of the plate 1 is fixedly connected with an adjusting support plate 3, and the inside of the adjusting support plate 3 is fixedly connected with a limiting track 4, and the inner rotation of the limiting track 4 is connected with an adjusting threaded rod 5, and the outer surface of the adjusting threaded rod 5 is sleeved and threaded. The transmission threaded block 6 is connected, and the outside of the transmission threaded block 6 is fixedly connected with the installation side frame 7, and one end of the installation side frame 7 at the front is fixedly connected with a slideway side shovel 8, and the installation side frame 7 on the left side is close to the front ...

Embodiment 2

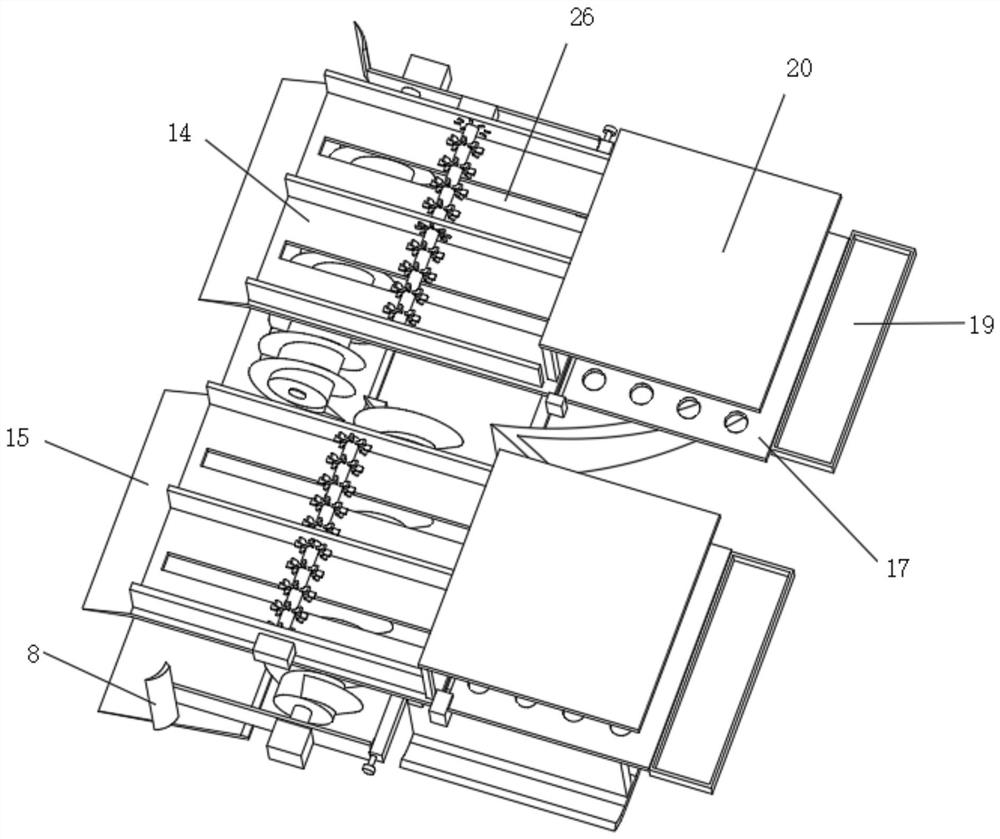

[0044] Such as Figure 5 Shown, on the basis of Embodiment 1, the present invention provides a kind of technical solution: a kind of ski resort skidway remodeling cleans up and uses snow layer to throw device, and electromagnetic drive mechanism 16 comprises drive shell 161, and the drive shell 161 One side is fixedly connected with the upper shovel rail 14, and the vertical position inside the drive housing 161 is slidably connected with a movable slider 162, and the right side of the movable slider 162 extends to the outside, and the right side of the movable slider 162 is connected to the sieve plate 17 fixed connections.

[0045] A magnet 163 is fixedly connected to the bottom of the movable slider 162 , an electromagnet 164 is fixedly connected to the inner bottom of the driving housing 161 , and an extruding spring 165 is sheathed and fixedly connected to the outside between the magnet 163 and the electromagnet 164 .

[0046] A power supply 166 is fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com