Fabricated prestressed high-strength concrete pavement

A high-strength concrete and prestressed technology, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of complex construction procedures, thick concrete road slabs, and long construction periods, and achieve flexural toughness, It is convenient for renovation and replacement, and the effect of quick assembly and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

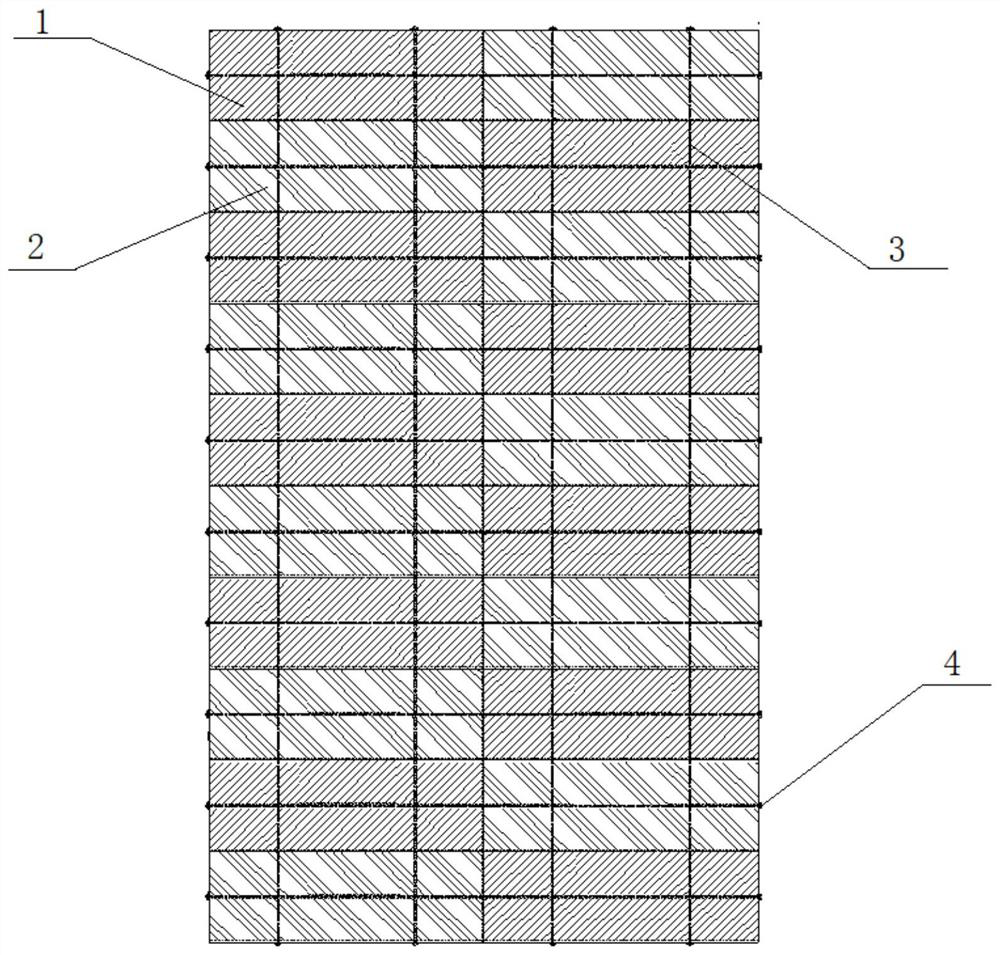

[0017] The invention provides an assembled prestressed high-strength concrete pavement, which includes more than two veneers, prestressed tendons, prestressed anchors 5 and assembly parts.

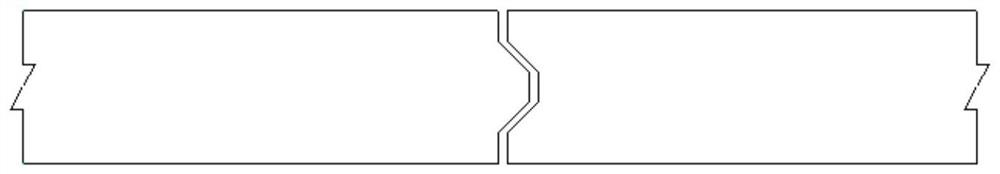

[0018] The veneer is made of high-strength concrete. High-strength concrete refers to active powder concrete with a compressive strength of more than 80MPa and good compressive and flexural toughness. The veneer is rectangular, which can be rectangular or square. The thickness of the veneer is 6 ~10cm, there are horizontal and vertical intersecting prestressed tendon channels inside, and the intersection point is a curved channel; two or more veneers can be inserted and assembled along the road horizontally, and can also be inserted and assembled along the longitudinal plates of the road. The center line of the body is laid out, and the corresponding prestressed tendon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com