Method for preparing collagen oligopeptide by hydrolyzing animal skin by using bacillus subtilis

A technology of Bacillus subtilis and collagen oligopeptides, applied in the biological field, can solve the problems of uneven molecular weight distribution of collagen oligopeptides, high cost of collagen oligopeptides, unfavorable absorption and utilization, etc., and achieve easy absorption and utilization, high content of hydrophobic amino acids , to achieve the effect of making full use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

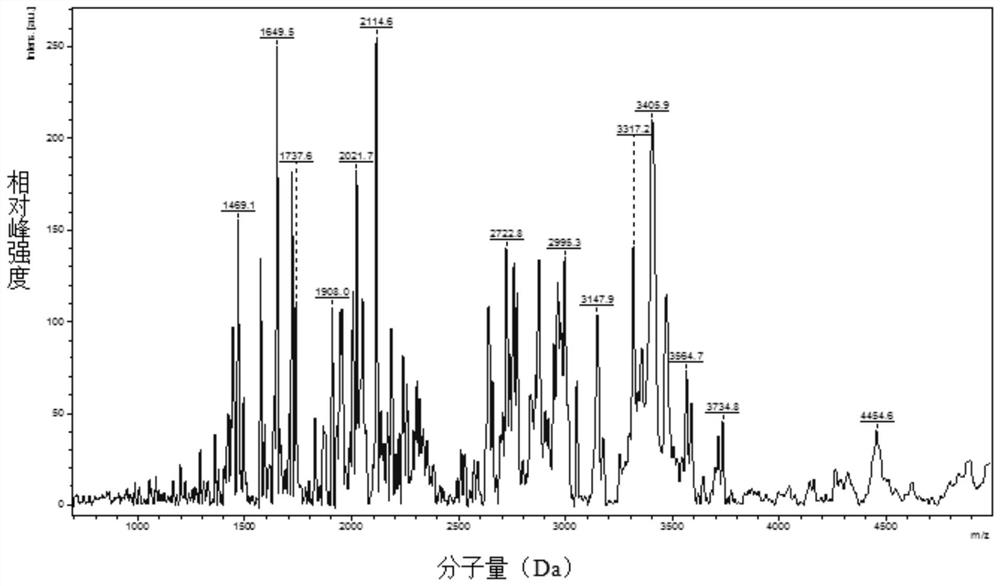

[0041] The preparation of embodiment 1 pigskin collagen oligopeptide

[0042] Including the following steps:

[0043] (1) Pick a single colony of Bacillus subtilis and inoculate it in the seed medium, cultivate it on a shaking table for 12 hours at a temperature of 30° C. and a rotating speed of 150 r / min, then inoculate it in the fermentation medium with an inoculum size of 6%, and Cultivate for 48 hours at a temperature of 30°C and a rotational speed of 150r / min; collect the fermentation broth of Bacillus subtilis, use casein as a substrate, and use the tyrosine assay method to measure the enzymatic activity of collagenase, and measure the activity of Bacillus subtilis fermentation In the solution, the enzyme activity of collagenase is 509U / mL;

[0044] (2) After simply cleaning the pigskin, remove the hair on the surface of the pigskin and scrape off the fat on the surface of the pigskin with a knife, then grind the pigskin with a meat grinder, and finally dry the ground p...

Embodiment 2

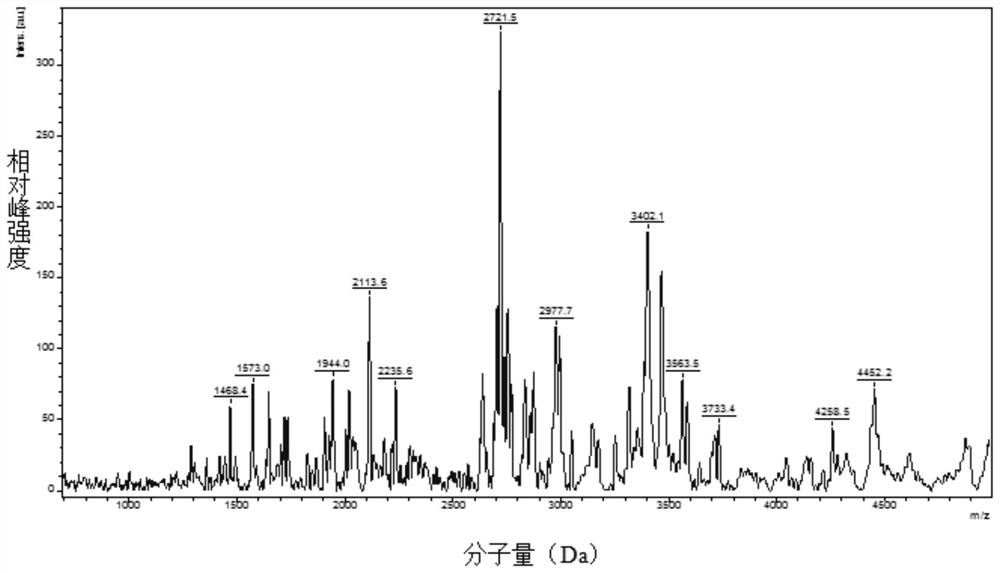

[0049] The preparation of embodiment 2 fish skin collagen oligopeptides

[0050] Including the following steps:

[0051] (1) The preparation method of Bacillus subtilis fermented liquid is the same as embodiment 1, and the activity size of collagenase is 509U / mL;

[0052] (2) After the fish skin is simply cleaned, remove the fat on the surface of the fish skin and a little residual fish scale, then grind the fish skin with a meat grinder, dry the minced fish skin in an oven at 50°C, and store it at -20°C for later use , to get fish skin powder;

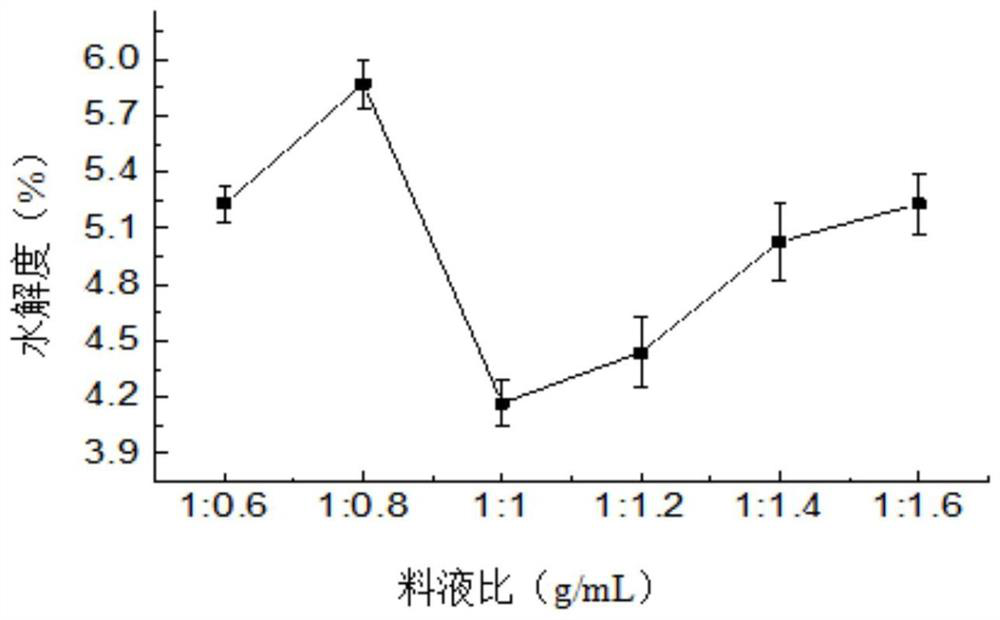

[0053] (3) Take fish skin powder, add distilled water according to the solid-liquid ratio of dried fish skin powder and distilled water 1:6.8g / mL, after mixing, sterilize the mixed solution at 121°C for 15 minutes to obtain the fish skin mixed solution;

[0054] (4) The step (1) of adding 34.3% of the mixed liquid volume of fish skin to hydrolyze the fish skin with the Bacillus subtilis fermented liquid, the hydrolysis time is 5h, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com